BRP-Rotax

MAINTENANCE MANUAL LINE

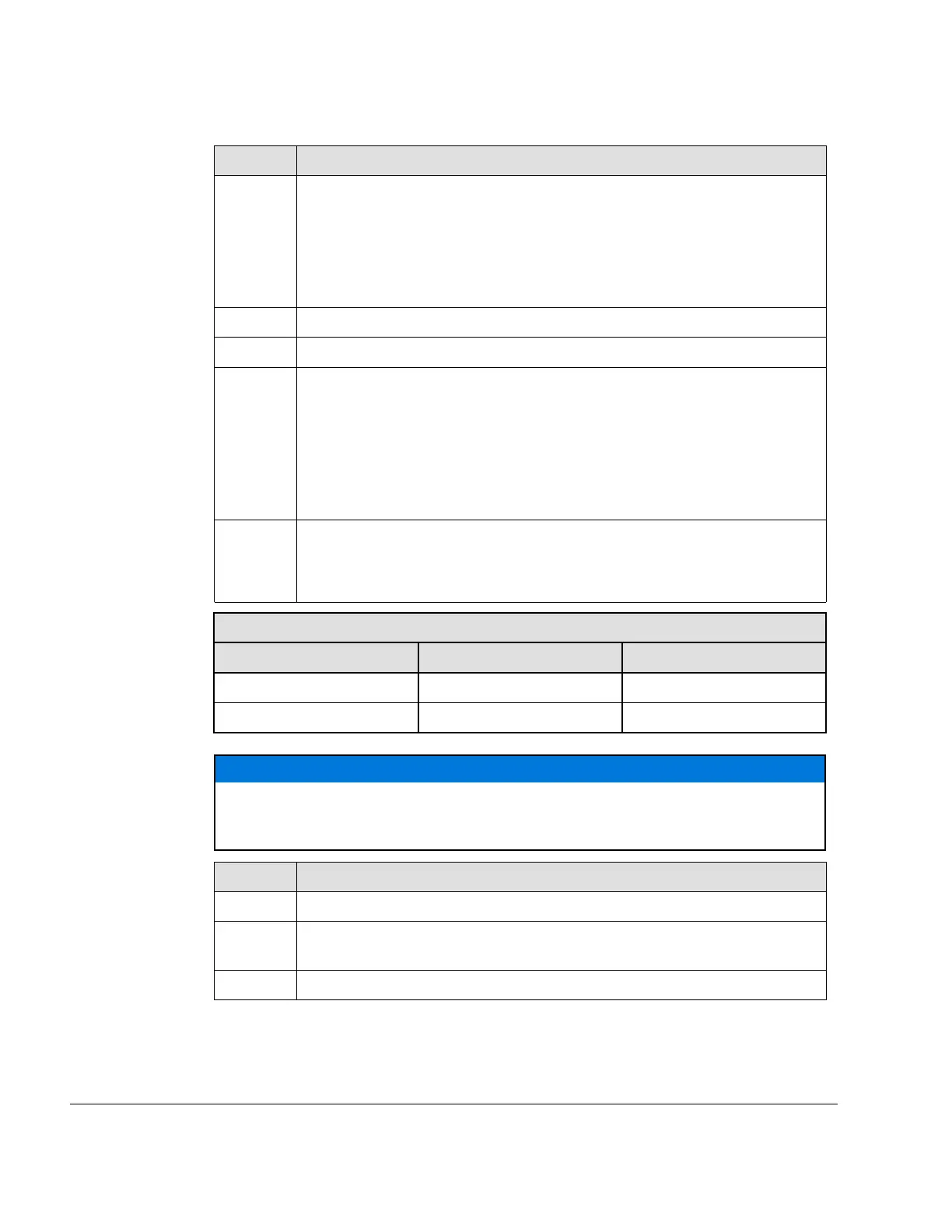

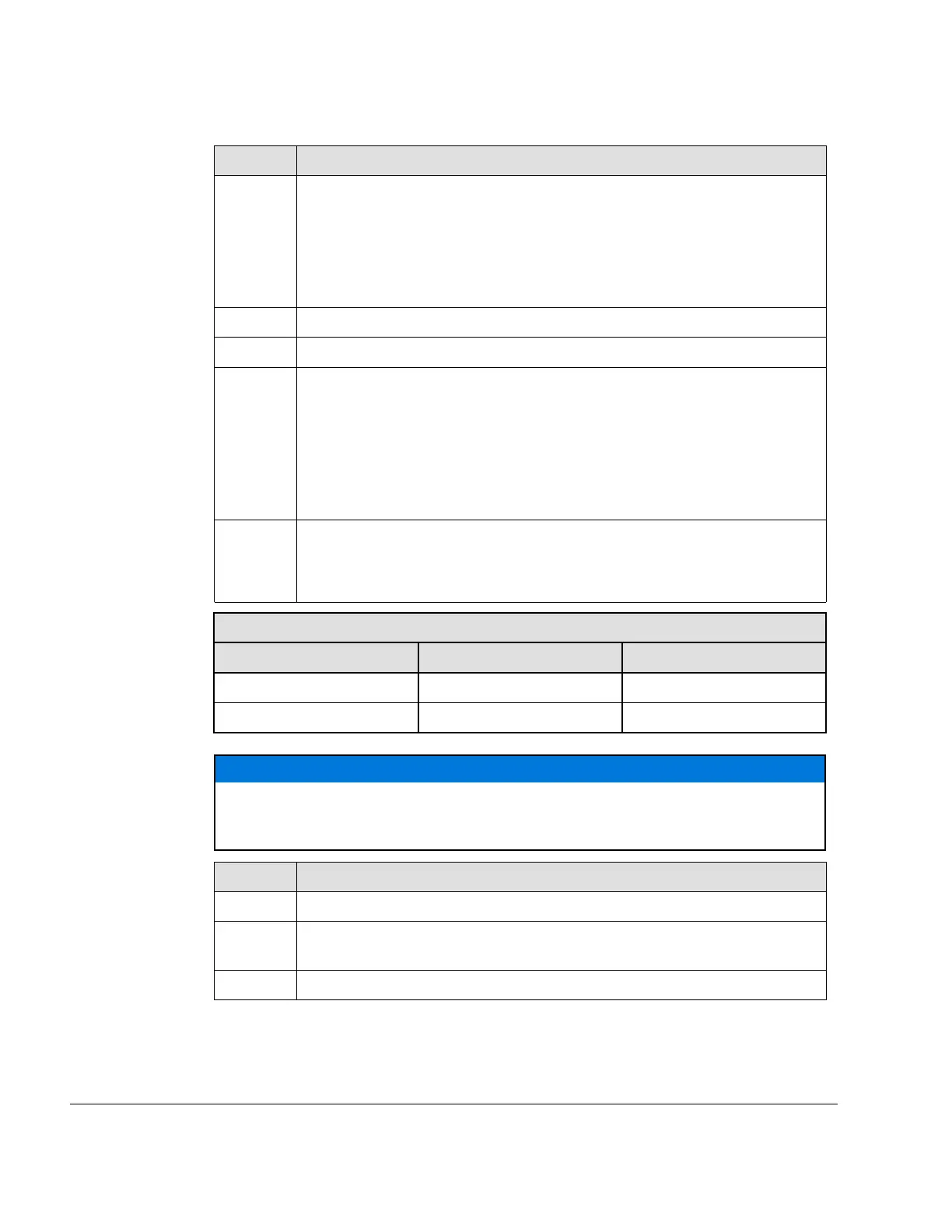

Step

Procedure

4

Attach and adjust outrigger of the torque multiplier. If the engine is mounted

in an aircraft, this one must be supported/fixed to the ground.

NOTE

Due to the torque multiplier the effective direction of the support de-

vice is opposite to the input direction of rotation..

5

Connect torque wrench to torque multiplier.

6

Turn over the clutch 3 times. (Do not record the measured values!).

7

Turn over the clutch and record the breakaway torque on the torque

wrench.

NOTE

Check transmission ratio of the torque multiplier.

To calculate the value the measurement must be repeated a few

times (min. 2x) in order to obtain a stable value.

8 Compare the measured value with the limits.

If the value is greater or smaller than the limit values, the overload clutch

must be inspected, repaired or overhauled in accordance with the BRP-Ro-

tax instructions for continued airworthiness.

Breakaway torque

Engine type minimum Limit maximum Limit

912 iS 600 Nm (442 ft.lb) 800 Nm (590 ft.lb.)

912 iS/iSc Sport 700 Nm (516 ft.lb.) 900 Nm (664 ft.lb.)

ATTENTION

The maximum limit must not be exceeded, otherwise it may cause a damage of

the gearbox. Values below the minimum limit may cause a slipping of the over-

load clutch that result in an overspeed.

Step

Procedure

9 Remove torque multiplier and torque wrench.

10

Remove the crankshaft. Locking pin, replace screw with new ring.

See Chapter 12-20-00 section Locking/loosen of the crankshaft.

11 Install the propeller according to the manufacturers instruction.

05–50–00

Page 14

September 01/2018

Effectivity: 912 i Series

Edition 2/Rev. 0

Loading...

Loading...