Section 5 Operating Instructions H85A Manual

www.rottlermfg.com

5-9

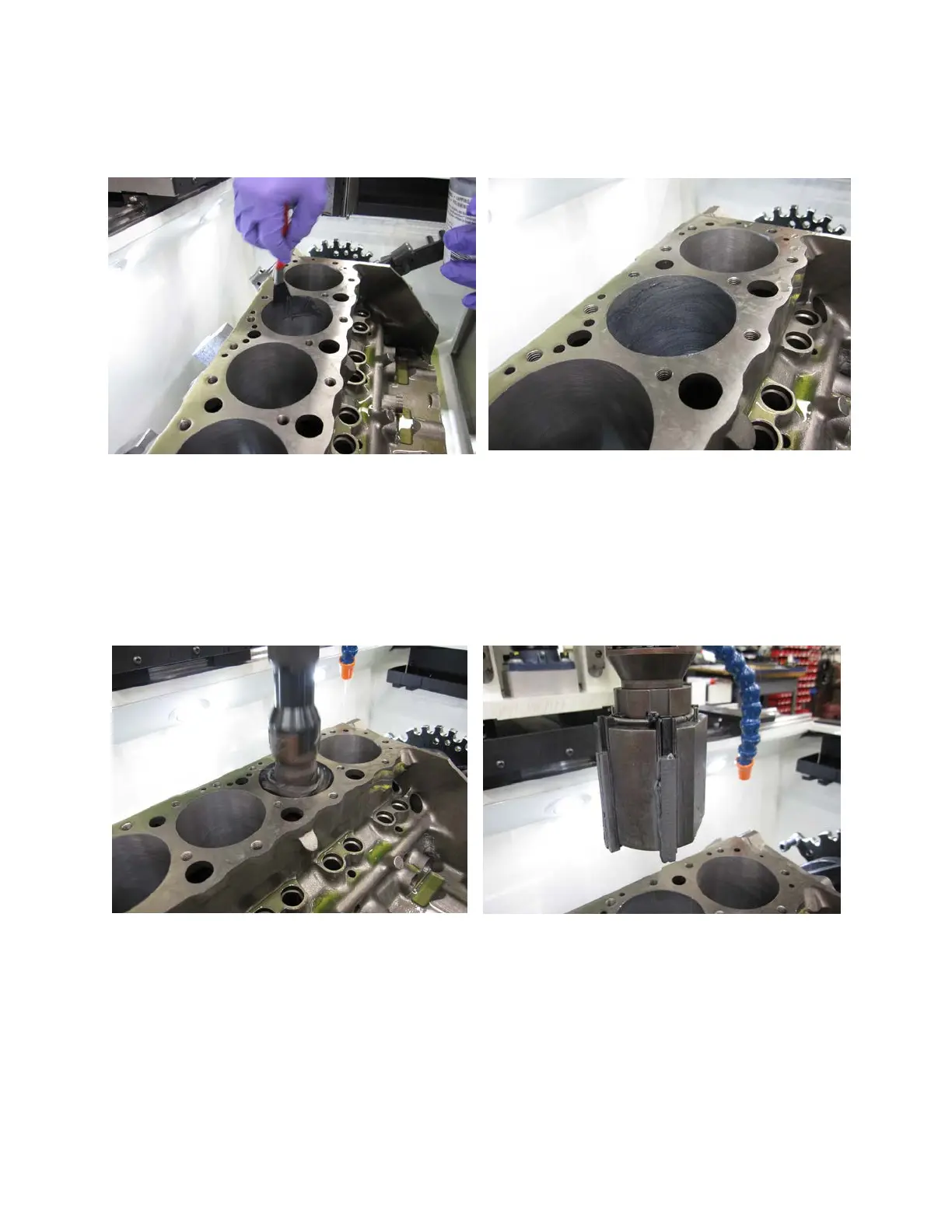

To start take a small brush and apply the lapping compound into the cylinder.

Set the cutting pressure in roughing and nishing mode to 20%. Set RPM to 80 rpm. You will need to set

the stock removal for .010 to .015 in (.254 -.381mm) the stock removal window as abrasive will wear

quickly with lapping compound. Insert hone head into bore. Start the machine with the coolant nozzle

pointed away from the cylinder. Do not use the ow valve to shut off ow from the pump as that will cause

the motor to overheat and trip out. You can shut the pump motor off in the Operation screen if you want.

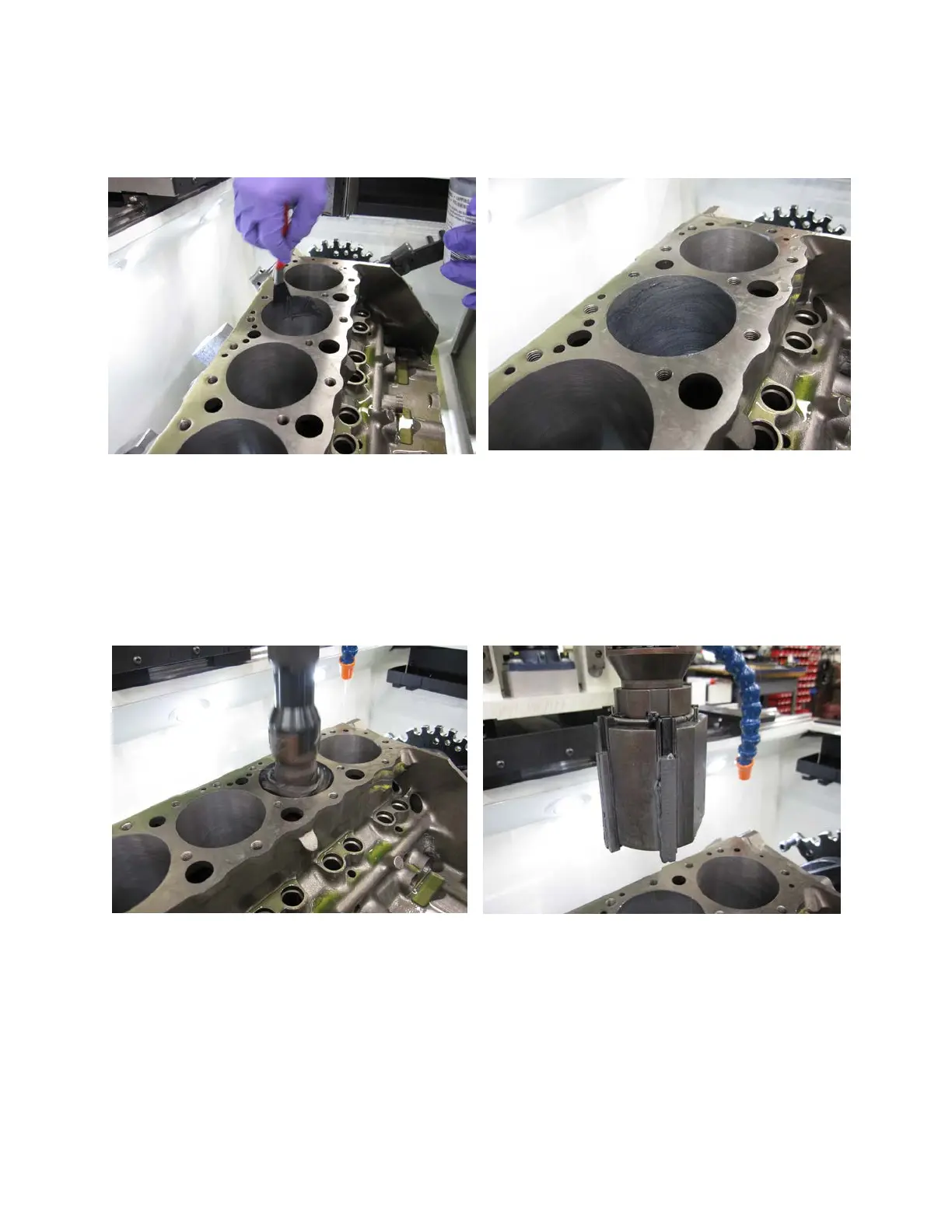

Run machine until it either shuts off or the DRO for stock removal stalls or quits moving. This indicates grit

has either worn down or been swept from between cylinder wall and abrasive.

Remove hone head and clean the abrasive. Closely look at abrasive to determine if there is a solid line

of contact the entire length of abrasive. If there is not a solid line contact on either the leading or trailing

edge of abrasive then repeat the process again.

Loading...

Loading...