PARTS LIST—ELECTRICIAN’S QUICK GUIDE

65

ELECTRICIAN’S QUICK GUIDE

The Rytec System 4 controller is a variable frequency

AC drive. This controller relies on the proper installation

and grounding of wiring and cabling for the controls and

motor. THE HIGH AND LOW VOLTAGE MUST BE SEP-

ARATE. FAILURE TO DO SO WILL VOID THE WAR-

RANTY. A door-specific electrical schematic has been

shipped inside the System 4 control panel. The electri-

cal schematic in this manual is a general schematic and

only used for reference. Use the schematic provided in

the control panel for the actual electrical installation.

NOTE: High voltage is any voltage exceeding 50

volts.

The System 4 control has a class 2 power

supply. Therefore, no voltage from any

other source can be introduced to the Sys-

tem 4 controller.

1. All entries to the control panel must be made

through the bottom of the control panel. Failure to

do so will void the warranty.

IMPORTANT: All conduit entering the control

panel must enter from the bot-

tom of the panel — High voltage

from the bottom left and low volt-

age from the bottom right.

Installing conduit through the

top or sides of the control panel

will void the warranty.

2. High voltage must run in metallic conduit and enter

the bottom left corner of the control panel.

3. All low voltage wiring is supplied by a class 2 power

supply and should be installed in accordance with

NEC and local electrical codes. Failure to separate

high and low voltage will void the warranty.

4. All cables are to be cut to length.

IMPORTANT: Do not bundle or coil excess

cables in the control panel or in

the head assembly of the door.

5. The motor ground (green wire) will terminate to

ground in the control panel. The drain wire (bare sil-

ver) will also attach to ground.

6. The encoder cable will enter the bottom right of the

control panel. The drain wire (bare silver) attaches

under the screw of the P-clip for the encoder cable

(see Figure 45).

NOTE: The encoder cable must be cut to length

and contain no loops or coils.

7. The remaining cable for the photo eyes and activa-

tors must also be cut to length and also contain no

loops or coils.

8. All field electrical work must conform to any applica-

ble local or national electric codes.

9. All field wiring to be minimum 60° C, 600 V rated

copper stranded type.

10. Use shielded cable where indicated on electrical

drawing.

IMPORTANT: Failure to use shielded cable

may result in improper operation

or premature failure and will

VOID the warranty.

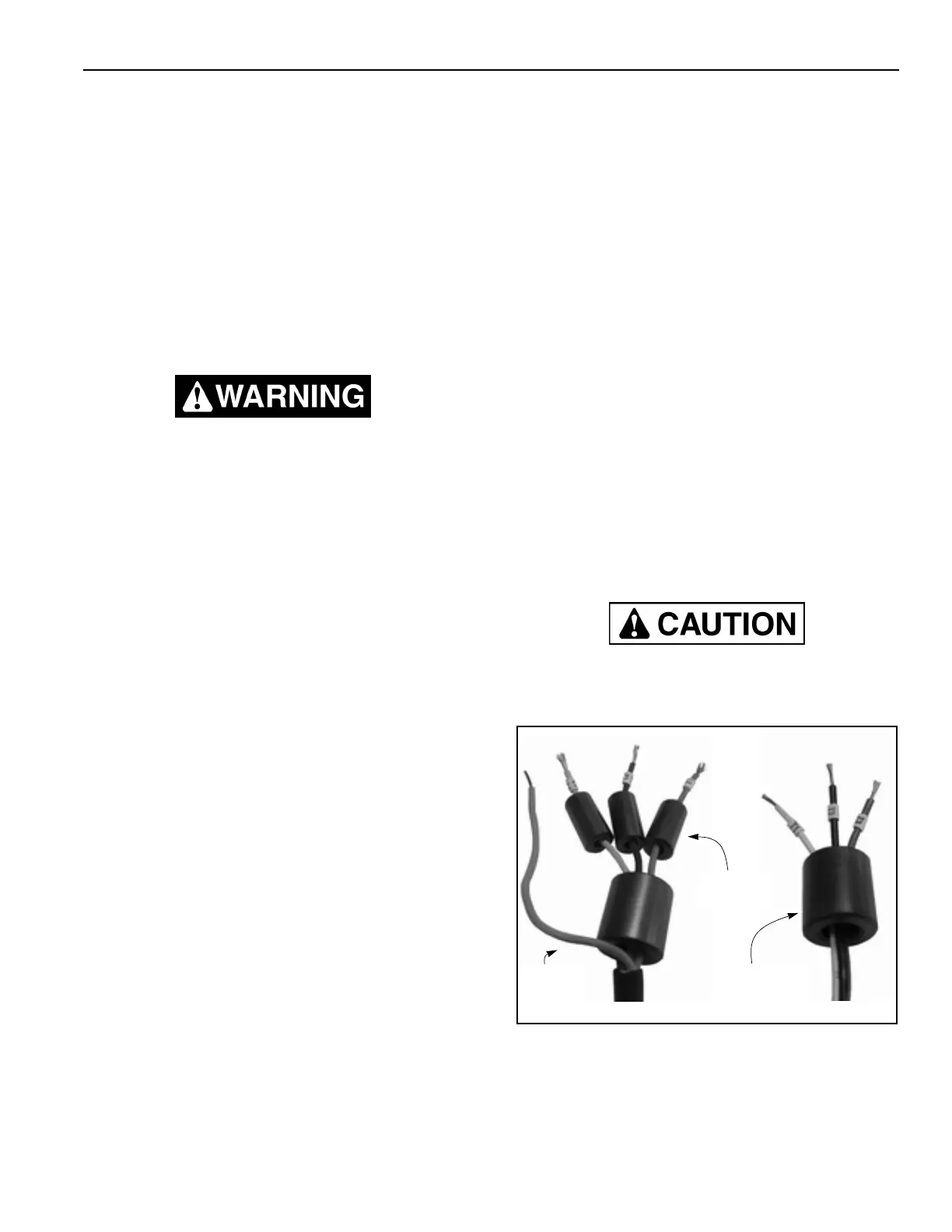

Ferrite core magnets are to be installed on the incoming

L1, L2, and L3 supply voltage wires and also on the T1,

T2, and T3 motor connections. The ferrite core magnets

act as a filter for the incoming supply power and voltage

passing to the motor. These filters help to reduce elec-

trical noise in the power system. See Figure 13 for

proper installation of the ferrite core magnets.

NOTE: Failure to install the ferrite core magnets

as illustrated will void the manufacturers

warranty.

Failure to install the ferrite core magnets will void

the manufacturer’s warranty and potentially cause

irreparable damage to the System 4 control panel.

Figure 53

A5400029-30

Motor Connection

Magnet Location

Supply Voltage

Magnet Location

Green

Ground Wire

Loading...

Loading...