10.7 PID control

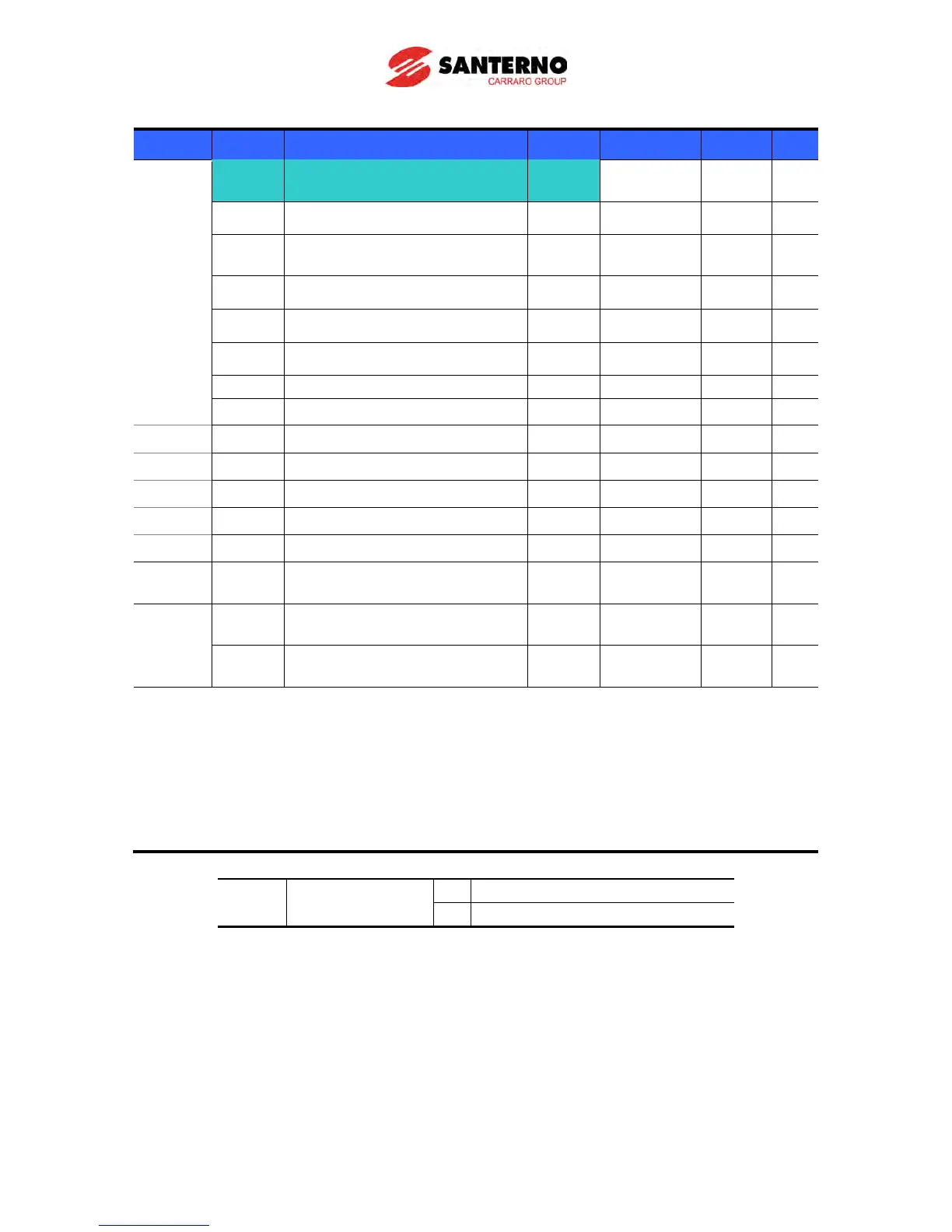

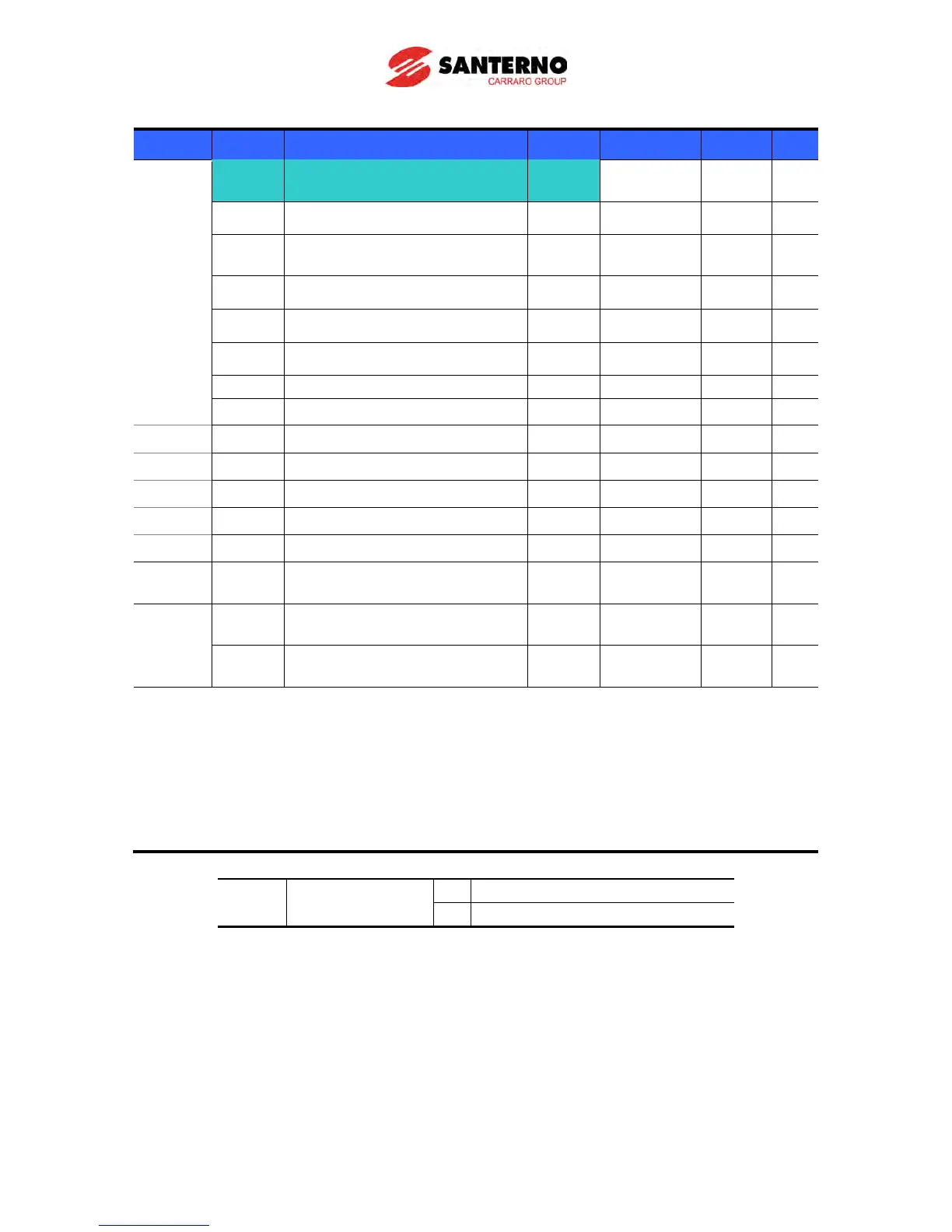

Group Display Parameter Name Setting Range Default Unit

H49 [PID Operation select] 1

0 ~ 1 0 -

H50 [PID Feedback select] - 0 ~ 1 0 -

H51

[Proportional gain for PID

control]

- 0 ~ 999.9 300.0 %

H52 [Integral time for PID control] - 0.1~ 32.0 1.0 sec

H53 [Derivative time for PID control ] - 0.0~30.0 0 sec

H54 [PID control mode select] - 0 ~ 1 0 -

[PID output frequency high limit]

H56 [PID output frequency low limit] - 0.1 ~ 400 0.50 Hz

H57 [PID reference source select] - 0~4 0 Hz

H59 [Inverse PID] - 0~1 0 -

H61 [Sleep delay time] - 0.0~2000.0 60.0 -

H62 [Sleep frequency] - 0.00~400 0.00 Hz

H63 [Wake-up level] - 0.0~100.0 35.0 %

[Multi-function input terminal

P1-P8 define]

group

rEF [PID reference] -

In order to control the amount of following water, pressure and temperature, do PID

control to inverter output frequency.

Select H49 of function group 2 as a 1 (PID drive select). Then REF and FBK category

show. Set PID reference value in REF and real PID feedback amount is monitored at the

FBK

PID drive is classified as Normal PID mode and Process PID mode. It can be set in H54

H50: Select the feedback type of PID controller.

select]

0 Terminal I input (0 ~ 20[mA] )

1 Terminal V1 input (0 ~ 10[V])

H51: proportional term (P), multiplying the difference between the reference (value to be

obtained from the physical quantity to adjust) and the feedback (value measured by the

physical quantity). That difference is called “error” and is multiplied by a constant (H51), “Prop.

Gain”). When H51 increases, the incidence of the proportional term in the regulator output

signal also increases (regulator becomes more “sensitive”) if the error is the same. Instability

occurs if H51 value is set too high.

H52: Integral time is important because allows to reduce to 0 the error at running operation

in order to keep the same value for both reference and feedback. Integral gain set the needed

time to correct the accumulated error. For example if H52 is set to 1 sec and the error

Loading...

Loading...