179

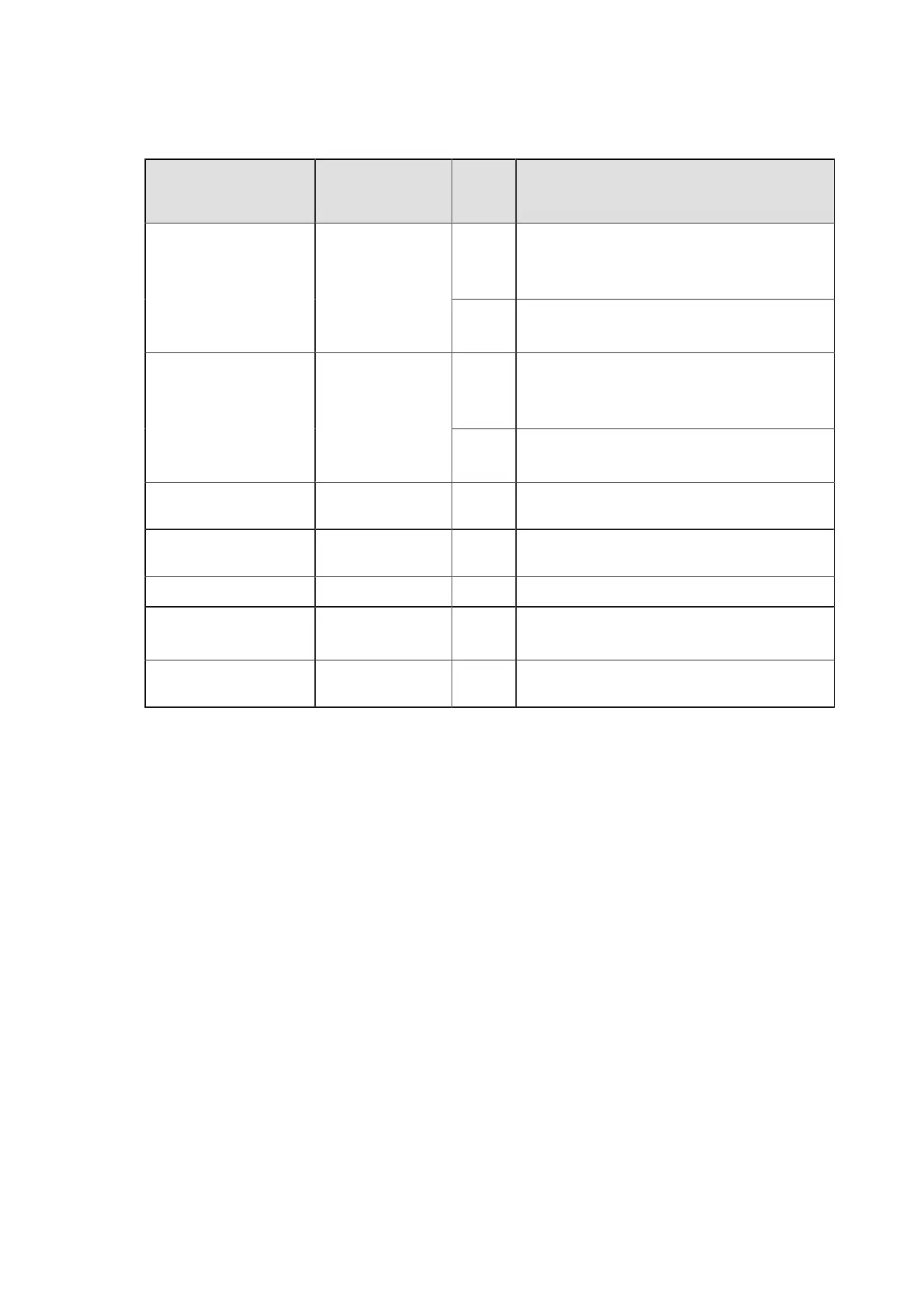

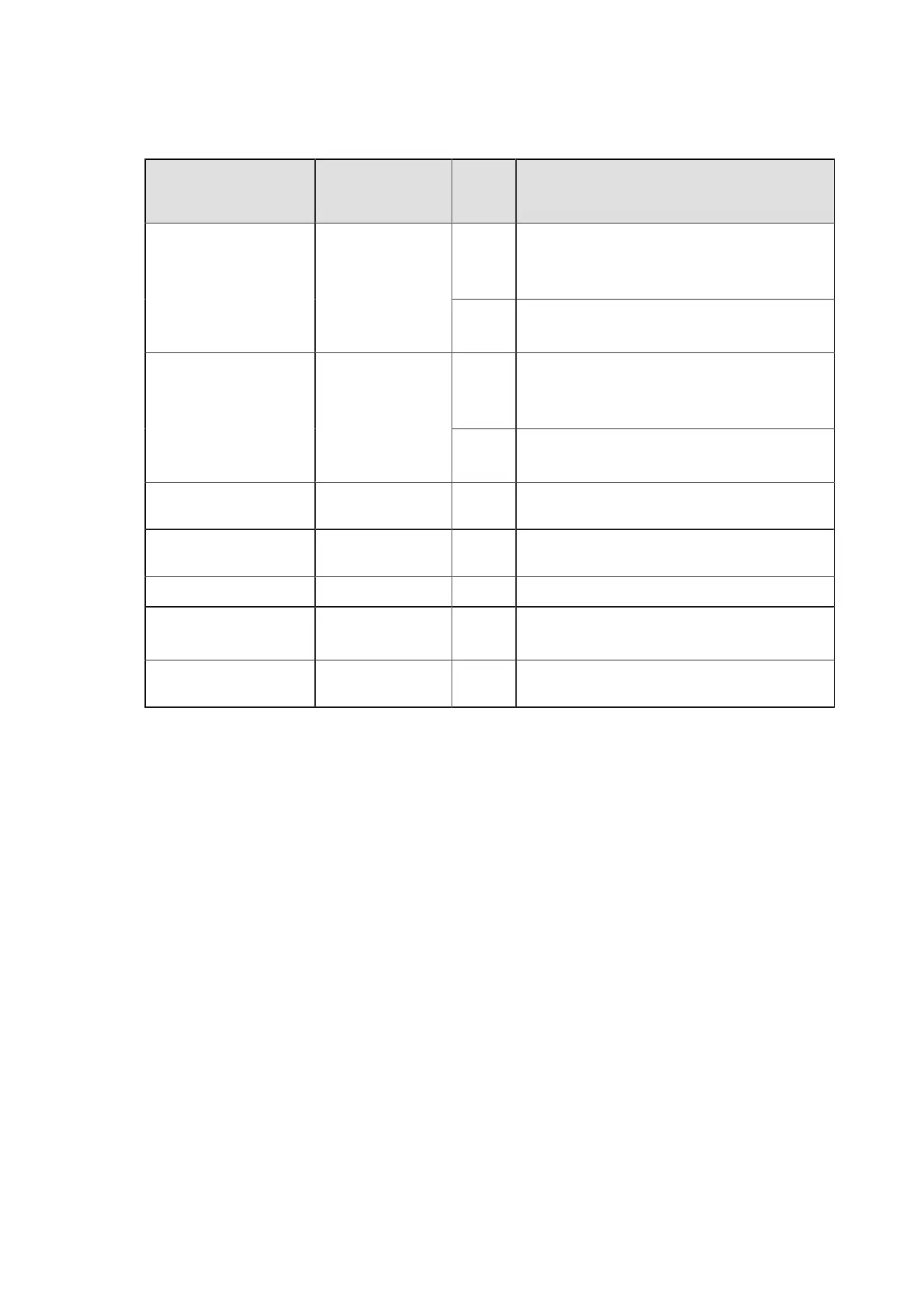

(5) Composition of check digit

Refer to the table below for check digit in each barcode.

[Composition of C/D]

Barcode specification

parameter

Barcode

specification

Input

digit

No.

Print digit number and contents

12-digit 13-digit

(Input data of barcode + C/D)

C/D is calculated by modulus10.

3 JAN/EAN13

13-digit 13-digit (Input data of barcode)

C/D is not checked.

7-digit 8-digit

(Input data of barcode + C/D)

C/D is calculated by modulus10.

4 JAN/EAN8

8-digit 8-digit (Input data of barcode)

C/D is not checked.

C CODE93 Max.

99-digit

C/D is calculated by modulus47.

E UPC-E 6-digit

only

C/D is calculated by modulus10.

G CODE128 - C/D is calculated by modulus103.

H UPC-A 11-digit

only

12-digit (Input data of barcode + C/D)

C/D is calculated by modulus10.

I UCC/EAN128 for

standard carton ID

17-digit

only

C/D is calculated by modulus103.

Note: C/D stands for "Check Digit".

(6) Barcode Rotation Print

Print direction of barcode can be rotated. Note that when specifying Serial 1 and Serial 2 for barcode

rotation, it may cause blurring due to barcode enlargement ratio.

Avoid printing of 1-dot narrow bar since 1 dot becomes 0.125 / 0.083 / 0.042 mm when head density

is 8 dots/mm (203 dpi) or 12 dots/mm (305 dpi) or 24 dots/mm (609 dpi).

Parallel 1: Forward feed print

Parallel 2: Backfeed print at 180-degree rotation

Serial 1: Forward feed print at 90-degree rotation

Serial 2: Forward feed print at 270-degree rotation

* Forward feed: Prints horizontally to label feed direction

Loading...

Loading...