Chapter 4 Fault diagnosis

SMSO-2-02.04- 15.07.03 95

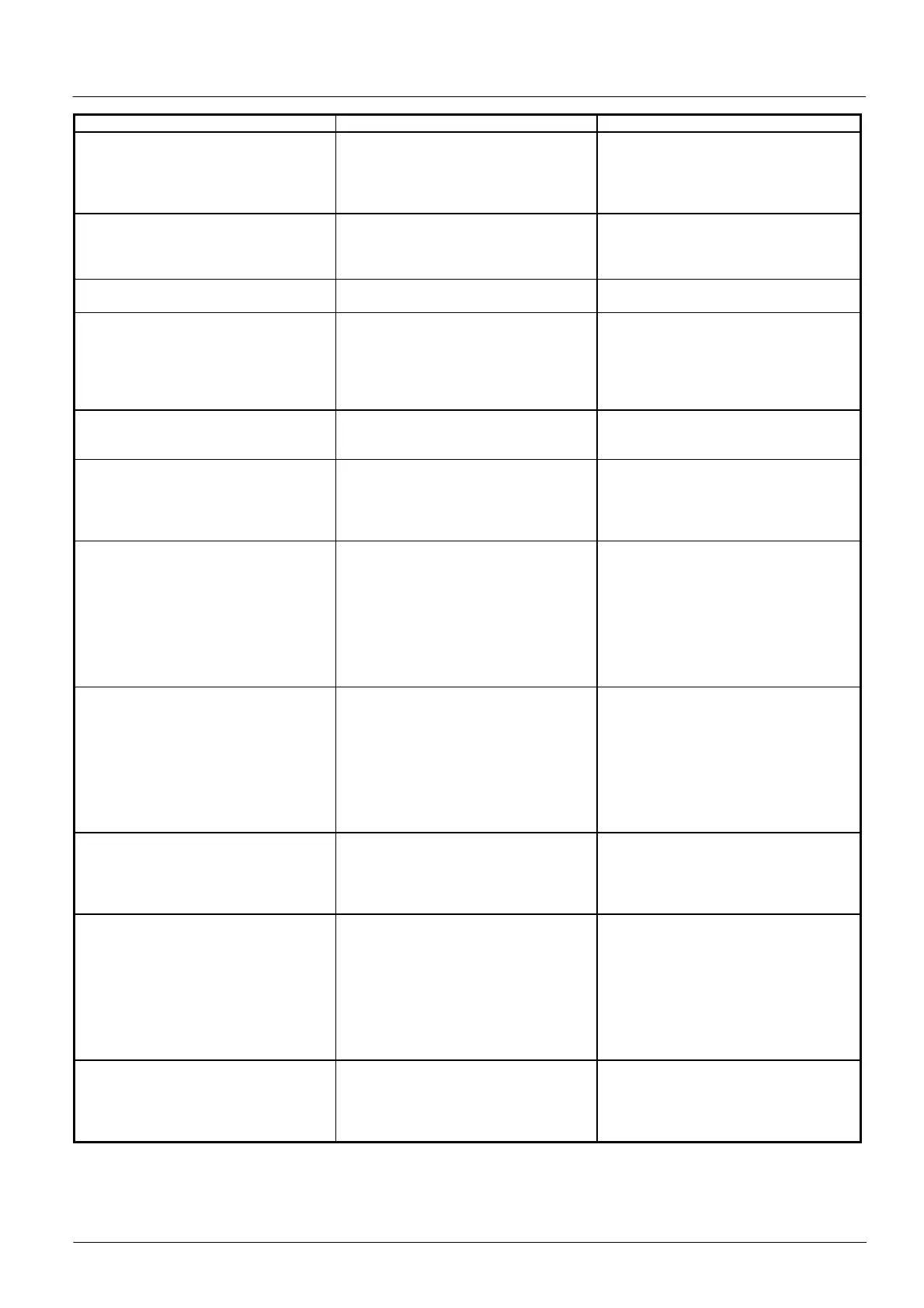

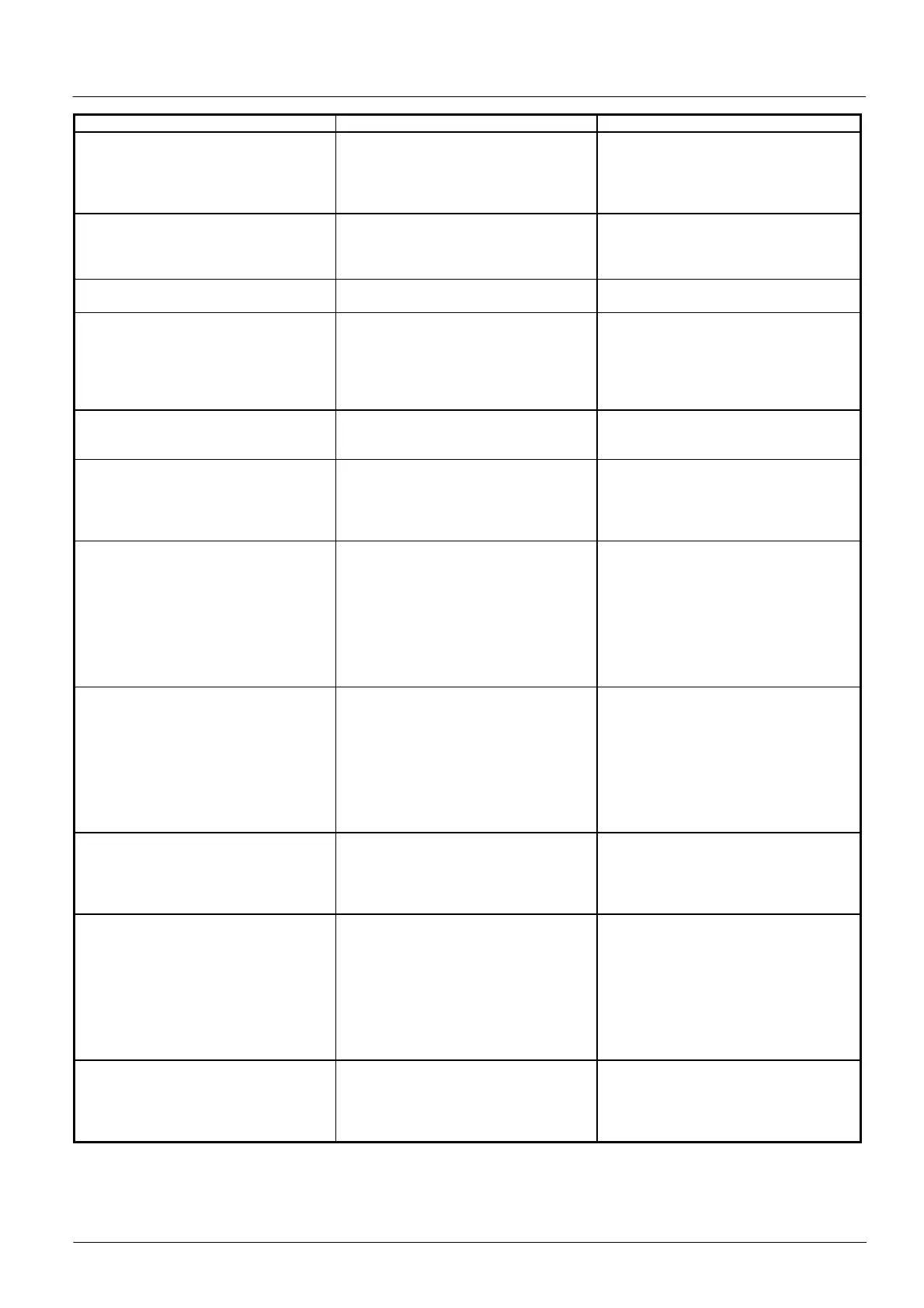

System / component Possible cause Remedy

piston motor timeout

Damage to motor or to gear

Position switch faulty or is not actu-

ated by the brewing unit

Electrical test on motor: see “control

system diagram, piston motor”

Functional check on position switch;

if necessary set the switch position or

replace the position switch

Selection locked

comms. interrupted

Interruption between RS 232 inter-

face and accounting unit

Check the cable and/ or the supply

voltage.

Check using the Info folder, sections

6/7

Selection locked

** LAN-Timeout **

Selection locked

milk door open

The limit switch is not in the correct

position (screw loose)

The door limit switch is faulty

Check if the door operating pin is

able to actuate the button roller; fas-

ten the switch into the correct posi-

tion.

Electrical check: see “control system

diagram, refrigerator cover switch”

motor current

Current to switch off piston motor not

reached.

Check the “compaction pressure”

setting and readjust if necessary

Replace the piston motor

motor driver error

Concerns the grinder and the piston

motor control system when an inter-

nal measurement is made on the

power PCB there is current, but no

motor is actuated.

Replace the power PCB

Select product

grinder left blocked

Foreign bodies in the grinder, so that

the grinder blades are blocked.

Damage to motor or to gear

Clean the grinder: see “Repairs,

dismantling/replacing grinder

blades”)

Electrical test on motor: see “Control

system diagram, left-hand grinder

motor”.

Replace the motor: see “Dismantling

components, dismantle/replace

grinder”

Select product

grinder right block.

Foreign bodies in the grinder, so that

the grinder blades are blocked.

Damage to motor or to gear

Clean the grinder: see “Repairs,

dismantling/replacing grinder

blades”)

Electrical test on motor: see “Control

system diagram, right-hand grinder

motor”.

Replace the motor: see “Dismantling

components, dismantle/replace

grinder”

level probe steam

After two minutes of feed time, the

water level in the steam generator

still not reached.

Faulty feed valve

Calcified level probe

Calcified water supply

Electrical check: see “Control system

diagram, level probe steam”

Product ## Error!

Error in RAM Check the parameters for the product

button concerned for unrealistic set-

tings End programming, switch the

machine off and then on again. If the

error is still present: Carry out a Con-

fig.-Reset, reprogram (with Save

Data cards). If the fault still cannot be

rectified, replace the unit control sys-

tem.

Selection locked

container n.i. place

The limit switch is not in the correct

position (screw loose)

The limit switch to the drawer for

coffee grounds is faulty

Check if the drawer is able to actuate

the button roller; fasten the switch

into the correct position.

Electrical check: see “Control system

diagram, drawer limit switch

Loading...

Loading...