MAINTENANCE PROCEDURES

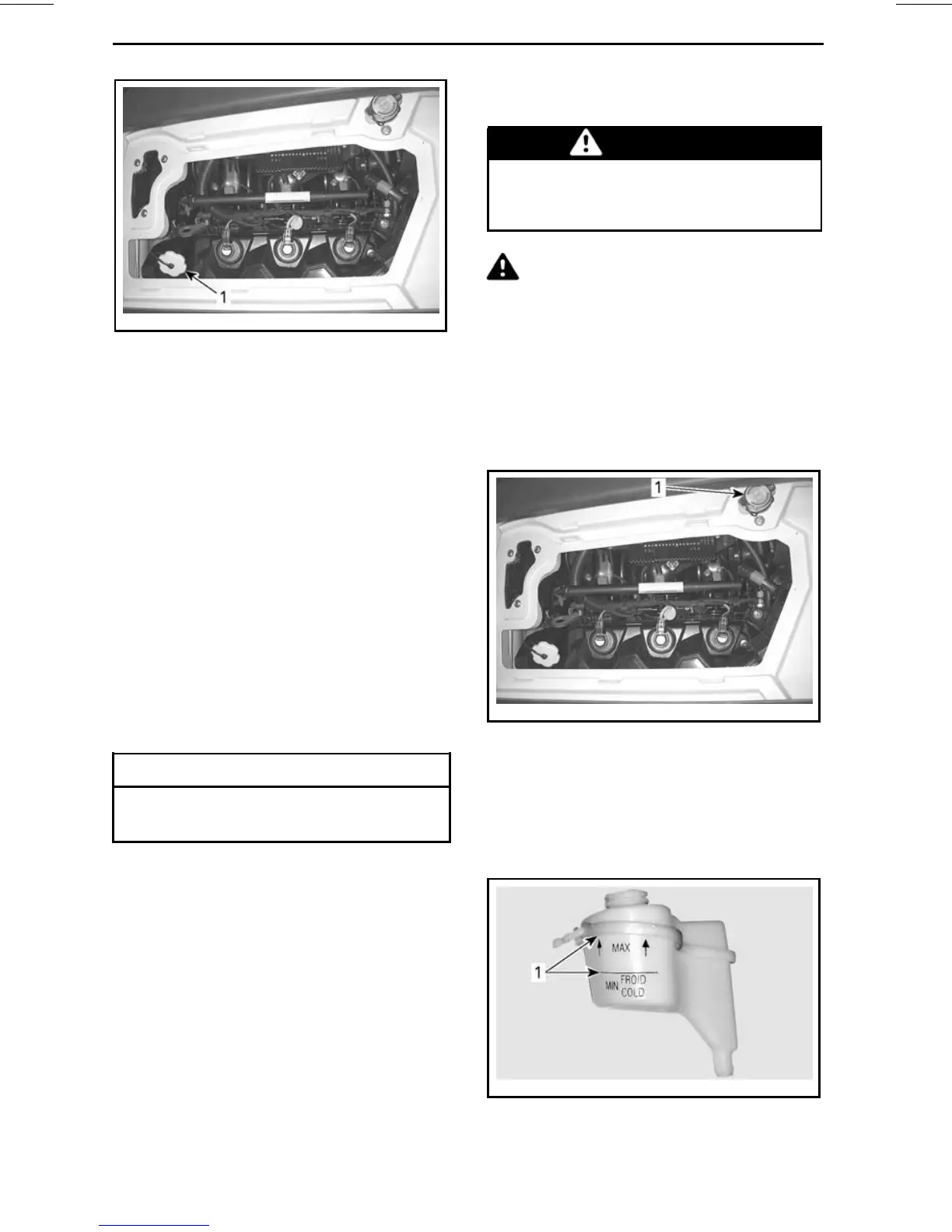

smo2009-002-003_c

TYPICAL - RXT iS ILLUSTRATED

1. Oil filler cap location

NOTE: Every time oil is added in the

engine, the complete procedure ex-

plained in this section must be carried

out again. Otherwise, you will obtain a

false oil level reading.

10. Properly reinstall oil cap and dip-

stick.

Engine Oil Change and Oil Filter

Replacement

The oil change and filter replacement

should be performed by an authorized

Sea-Doo dealer.

Engine Coolant

Recommended Engine Coolant

RECOMMENDED COOLANT

BRP PREMIXED COOLANT

(P/N 219 700 362)

As an alternative, use ethylene-gly-

col antifreeze containing corrosion in-

hibitors specifically formulated for in-

ternal combustion aluminum engines.

NOTE: Using a blend of 40% an-

tifreeze with 60% demineralized wa-

ter will improve the cooling efficiency

when watercraft is used in particularly

hot weather and/or hot water condi-

tion.

Engine Coolant Level

WARNING

Check coolant level with engine

cold. Never add coolant in cooling

system when engine is hot.

CAUTION Certain compo-

nents in the engine compartment

may be very hot. Direct contact may

result in skin burn.

Open seat.

Remove ventilation box. Refer to EN-

GINE OIL LEVEL for the procedure.

Locate the expansion tank cap.

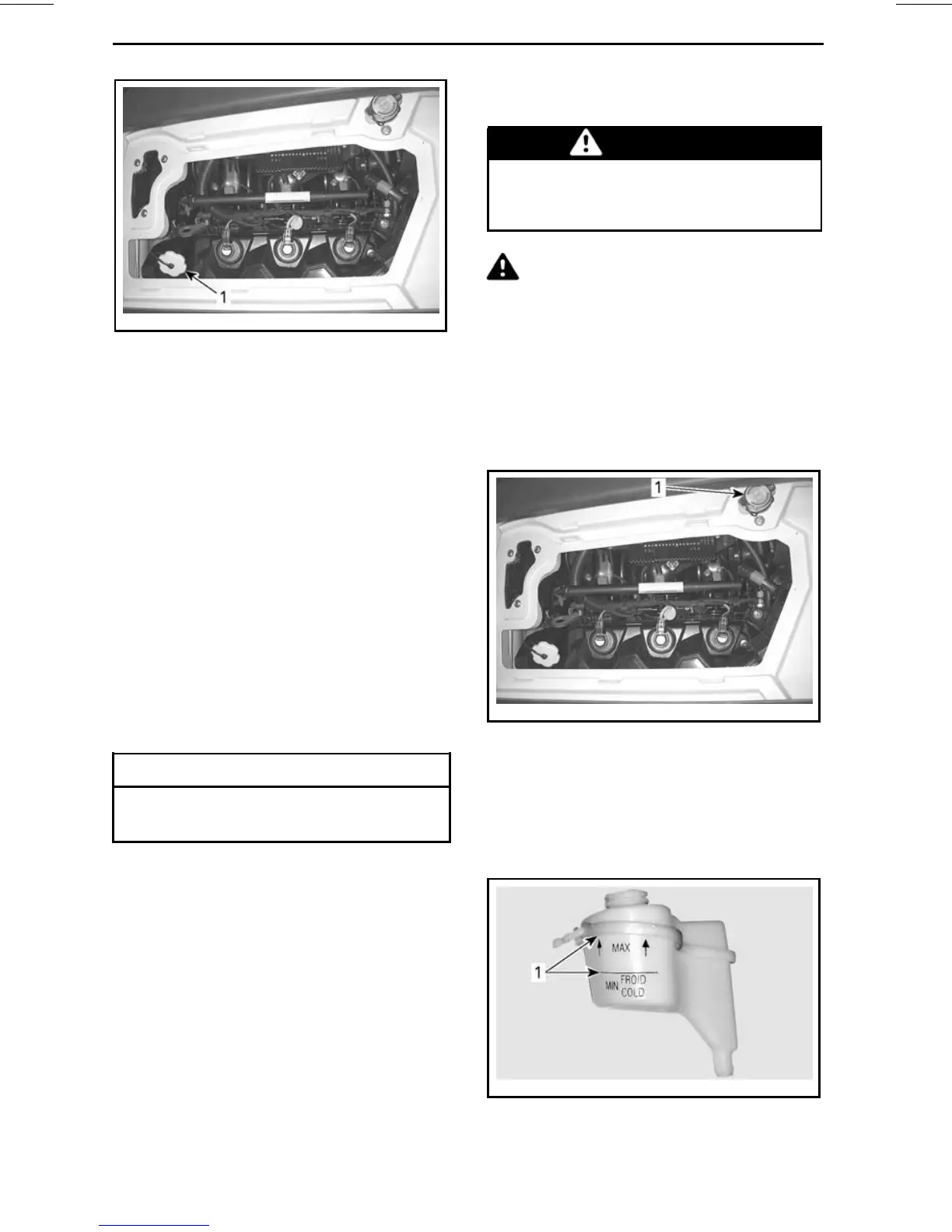

smo2009-002-003_d

TYPICAL - RXT iS ILLUSTRATED

1. Expansion tank cap

With watercraft on a level surface,

coolant level should be between MIN.

and MAX. marks on coolant reservoir

when engine is cold.

smo2009-002-137_a

TYPICAL - COOLANT EXPANSION TANK

1. Level between marks when engine is cold

132

______________

Loading...

Loading...