MAINTENANCE PROCEDURES

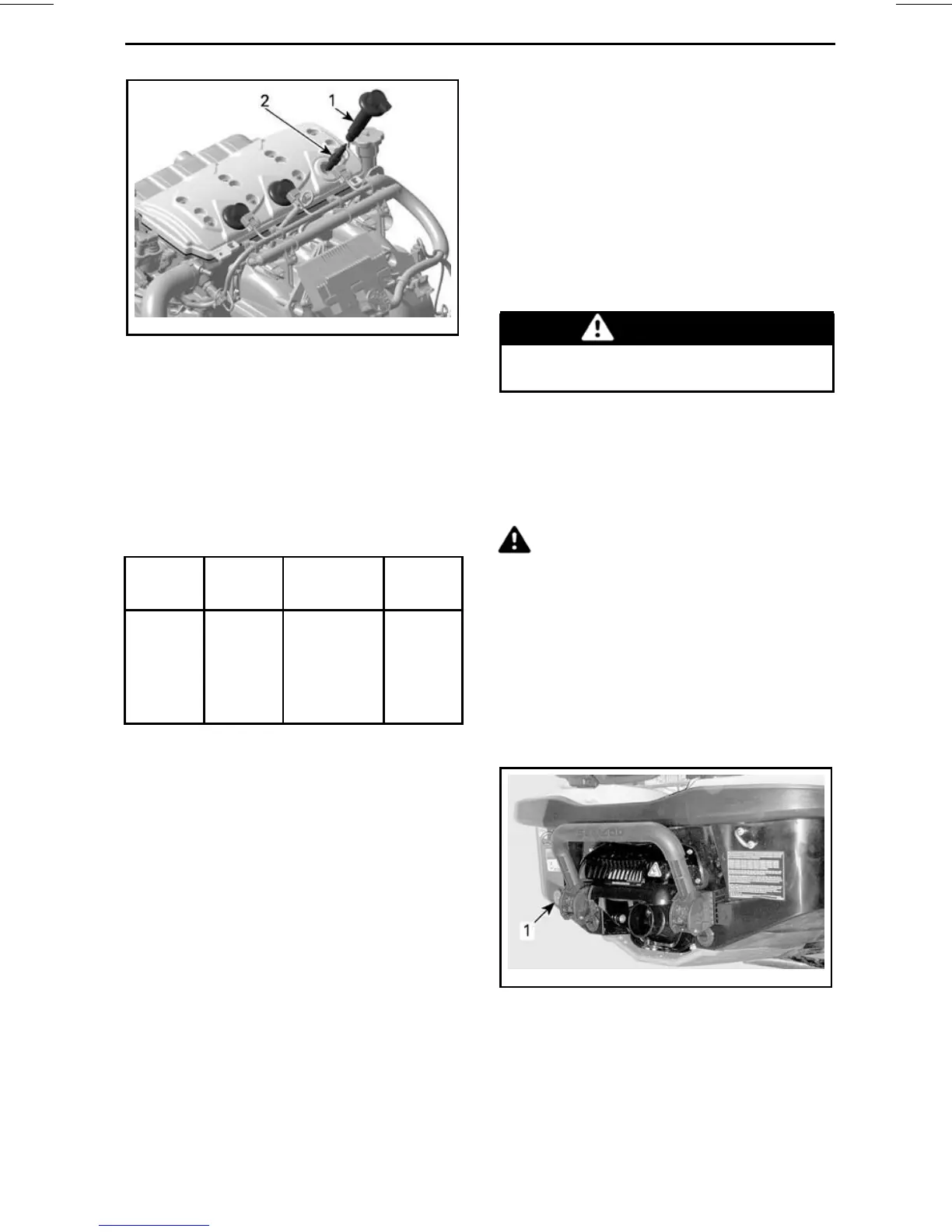

smr2009-032-003_a

1. Ignition coil

2. Spark plug

Spark Plug Installation

Prior to installation, ensure the contact

surfaces of the cylinder head and spark

plug are free of grime.

1. Using a wire feeler gauge, set elec-

trode gap as specified in the follow-

ing chart.

ENGINE

SPARK

PLUG

TORQUE

GAP

mm (in)

1503

NGK

DCPR8E

Hand

tighten

+ 1/4 turn

with a

socket

0.75

(.030)

2. Apply anti-seize lubricant over the

spark plug threads to prevent possi-

ble seizure.

3. Hand screw spark plug into cylinder

head. Then, tighten the spark plug

clockwise an additional 1/4 turn with

an approved spark plug socket.

Install ignition coil. Refer to

IGNITION

COIL INSTALLATION

.

Complete the installation in the re-

verse order of the removal.

Exhaust System

Exhaust System Flushing

Flushing the exhaust system and in-

tercooler (supercharged models) with

fresh water is essential to neutralize

corroding effects of salt or other chem-

ical products present in water. It will

help to remove sand, salt, shells or

other particles in water jackets and/or

hoses.

Flushing should be performed when

the watercraft is not expected to be

used further the same day or when the

watercraft is stored for any extended

time.

WARNING

Perform this operation in a well

ventilated area.

Proceed as follows:

Clean jet pump by spraying water in its

inletand outletandthen applyacoating

of XPS Lube or equivalent.

CAUTION When operating the

engine while the watercraft is out

of the water, the heat exchanger in

therideplatemaybecomeveryhot.

Avoid any contact with ride plate as

burns may occur.

Connect a garden hose to the connec-

tor located at the rear of watercraft (on

the port side of the stern). Do not open

water tap at this time.

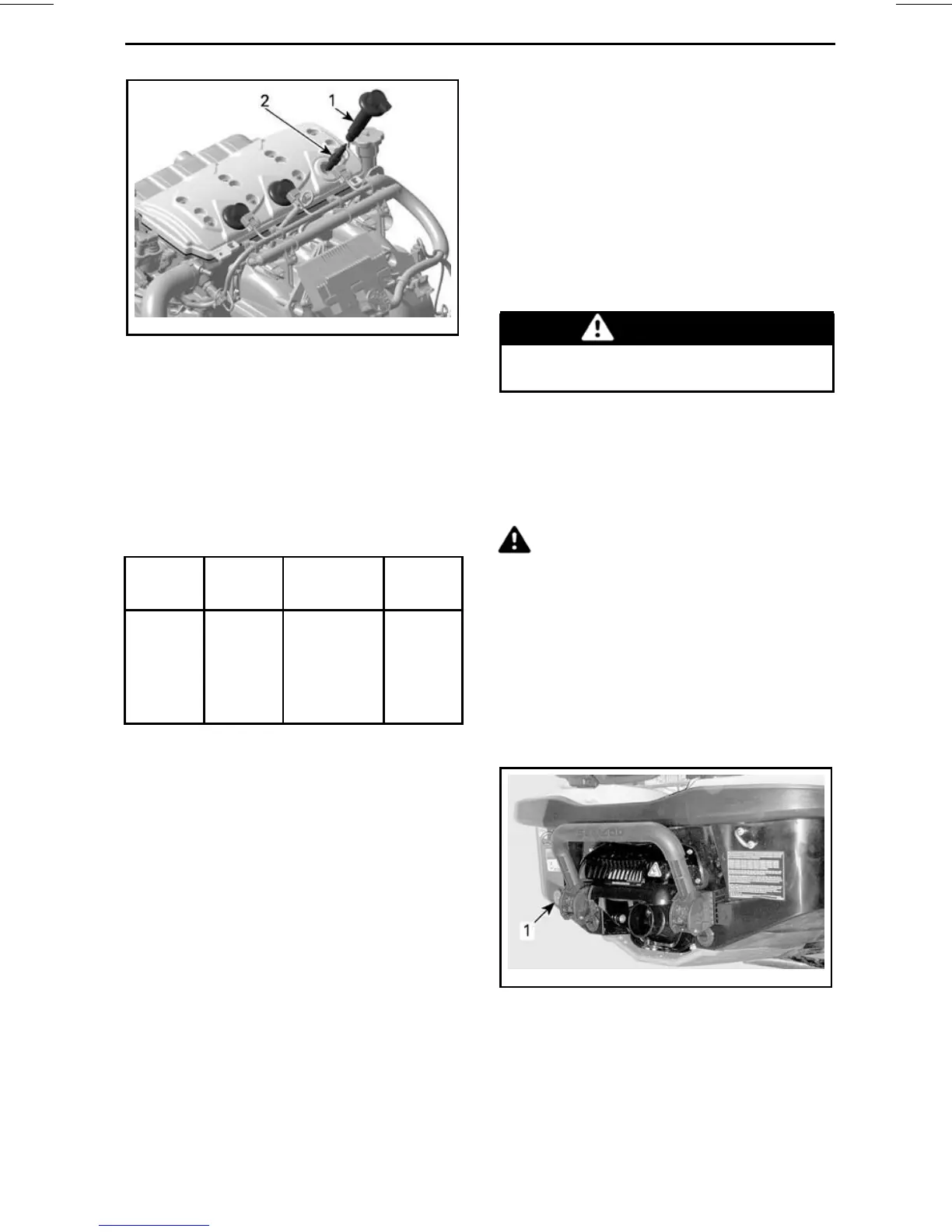

smo2009-002-132_c

TYPICAL

1. Flushing connector location

NOTE: An optional quickconnect hose

adapter and hose fitting can be used

(P/N 295 500 473). No hose pincher is

required to flush engine.

______________

135

Loading...

Loading...