70 DF-310E User Interface

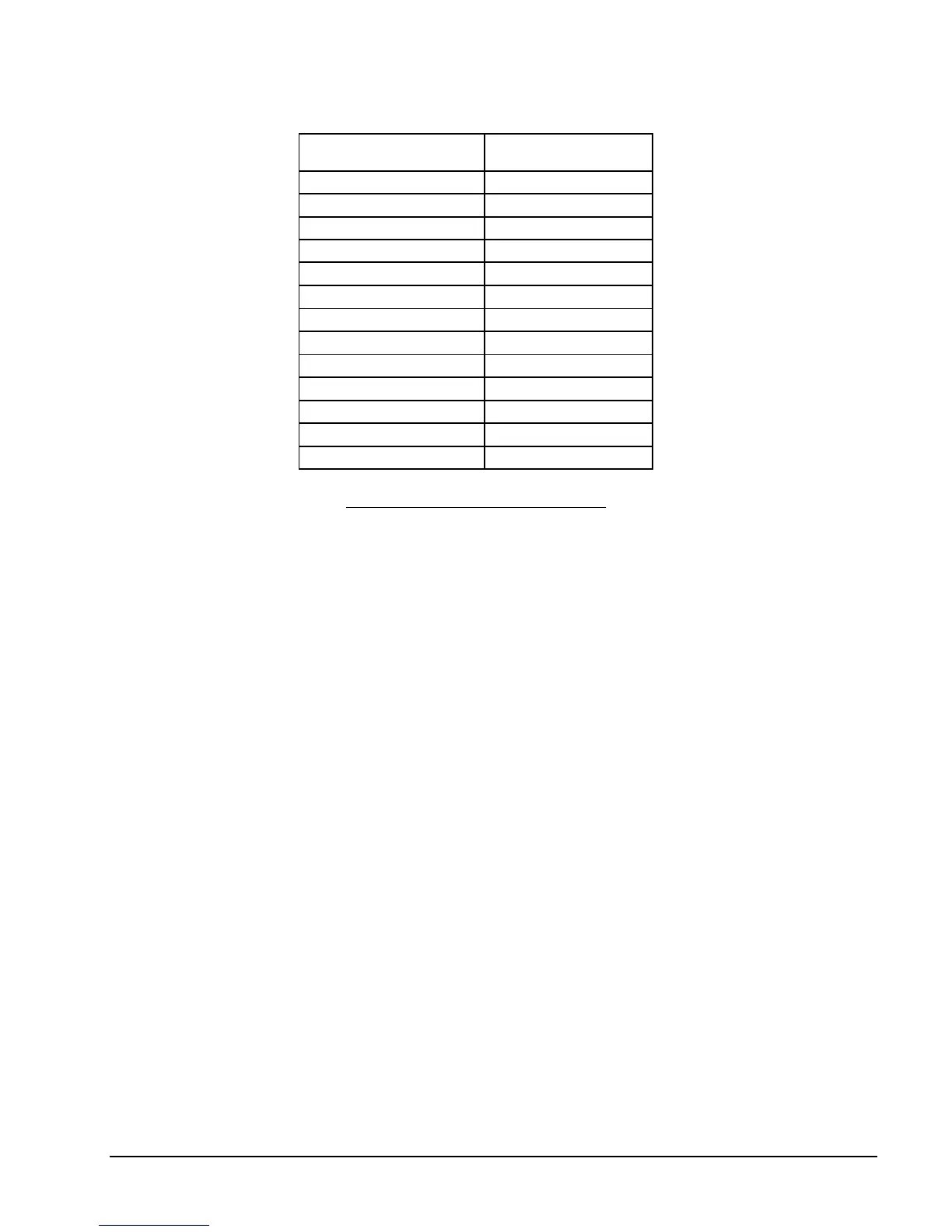

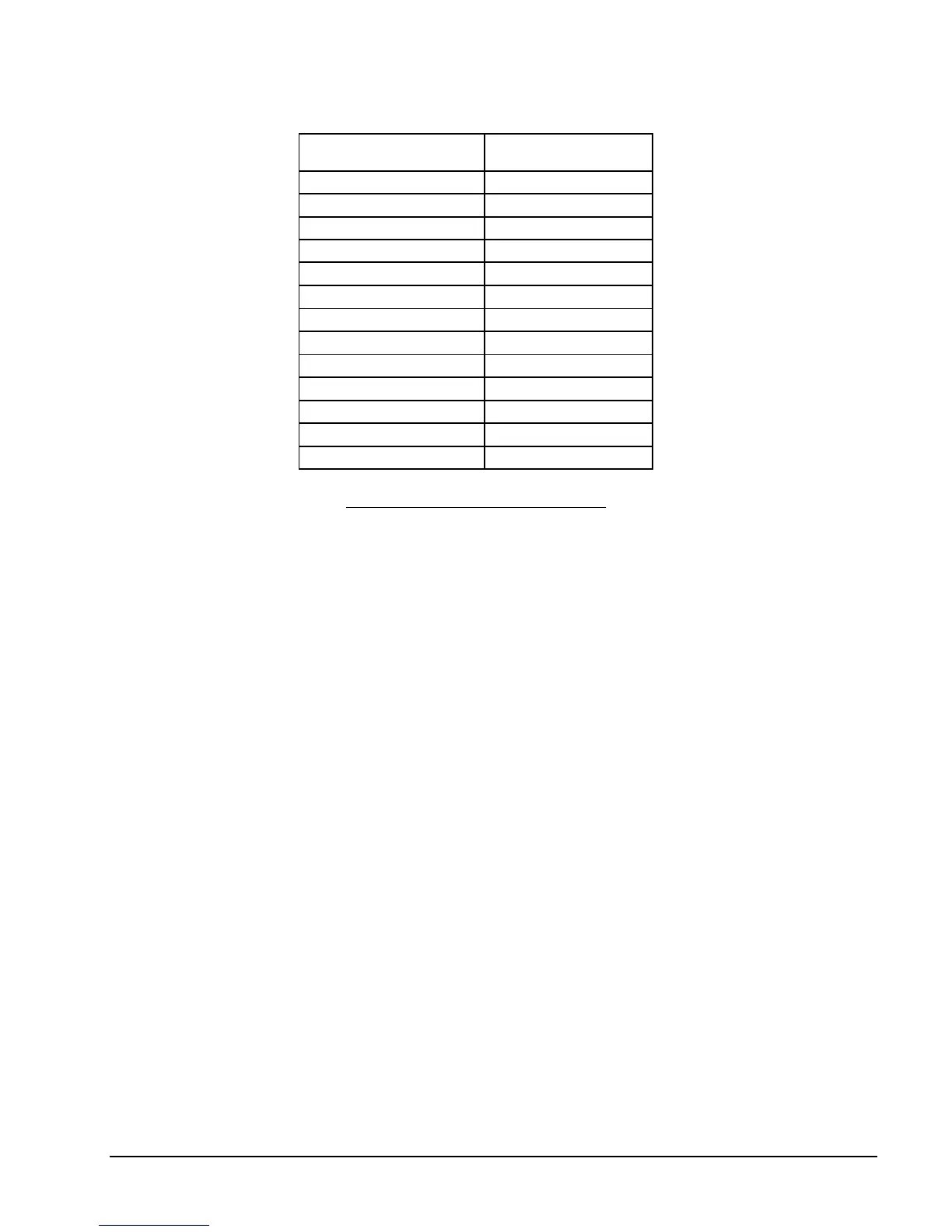

Background Gas Trip Point (scfh)

Air 0.25

Ammonia 0.33

Argon 0.22

Butane 0.18

Carbon Monoxide 0.26

Ethane 0.25

Ethylene 0.26

Helium 0.69

Hexane 0.15

Hydrogen 0.96

Methane 0.34

Nitrogen 0.26

Propylene 0.21

Table 13: Flow Switch Trip Points

From the Alarm Setup Menu, Figure 37, selecting FLOW Alm (ON) will bring a display similar

to Figure 39. The alarm can be assigned to any one relay.

The flow alarm is programmed in the same way as an O

2

alarm. However, the values for Hi Stpt,

Lo Stpt and Deadbnd will indicate NA. These values cannot be accessed.

8.4.1.4 Electrolyte Condition Alarm

The ELEC alarm is used to indicate electrolyte condition. From the Alarm Setup Menu, Figure

37, selecting the ELEC Alm (ON) will bring a display similar to Figure 39. The alarm can be

assigned to any one relay.

The electrolyte condition alarm is programmed in the same way as an O

2

alarm. However, the

values for Hi Stpt, Lo Stpt and Deadbnd will indicate NA. These values cannot be accessed.

8.4.2 Analog Outputs

The Outputs entry in the Setup Menu, Figure 36, is used to scale the full range of the analog

output (voltage and current) over a partial or full range of oxygen concentration.

NOTE: Alarm or Analyzer status conditions that signal an “Analyzer off-line” fault condition

(such as sensor off) can be assigned to a single relay contact used as a trouble indicator. If the

Analyzer signal is only monitored remotely, it is suggested to route the 4-20 mADC signal

through the “Analyzer Trouble” relay such that an alarm condition will cause the relay to break

the current loop. This method allows a computerized system to be configured to detect an

analyzer fault condition whenever the 4-20 mADC signal is below 4 mA. After accessing the

Outputs on the Setup Menu, Figure 36, the display will be as shown in Figure 41.

Loading...

Loading...