Plasma Gas Analyzer

27 02001001A_9

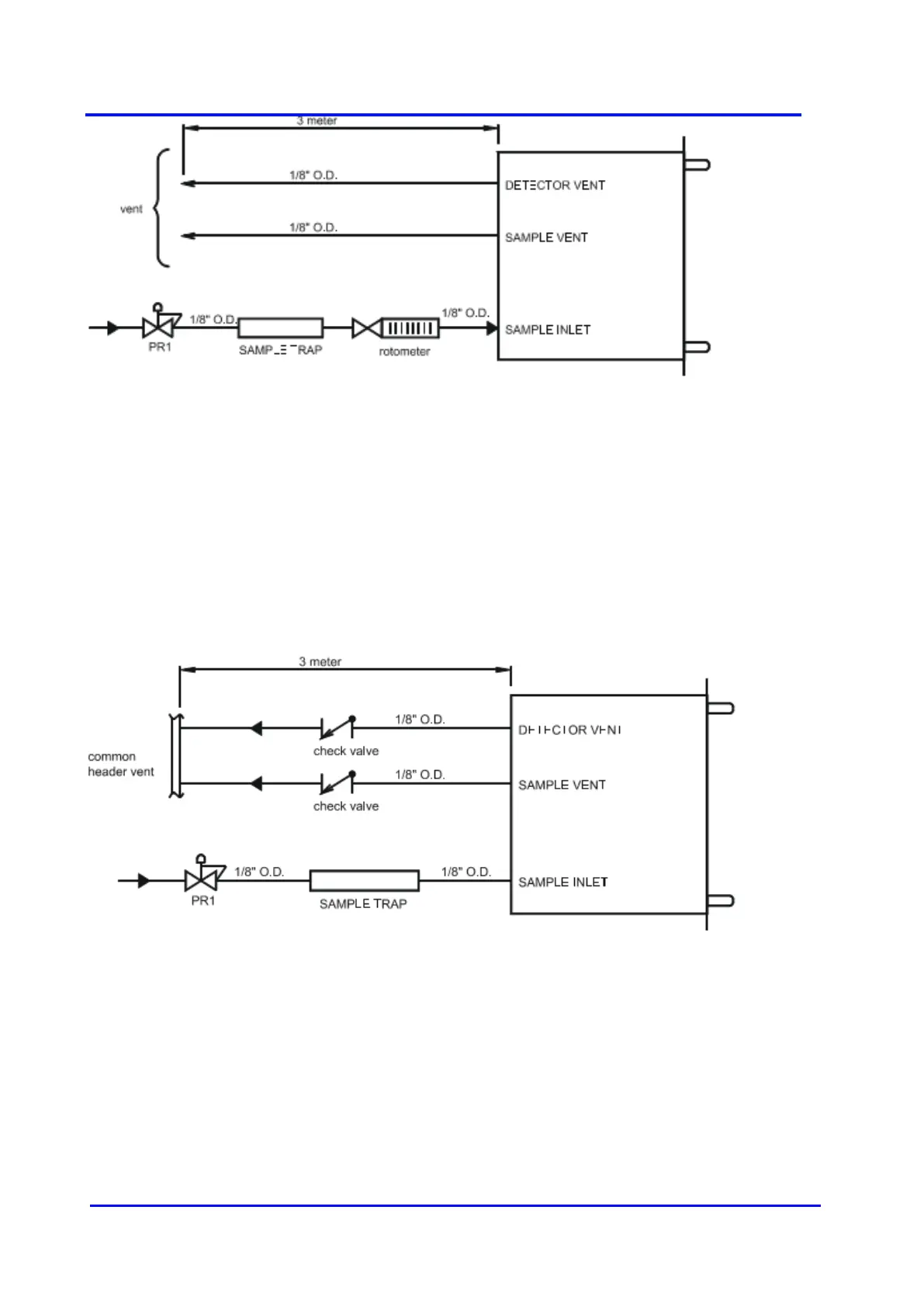

Figure 14 - POOR INSTALLATION EXAMPLE 2

Some users wish to monitor the inlet flow with a falling ball rotameter. Those rotameters (or

flowmeters) are calibrated at atmospheric pressure. The flow indicated will be wrong, it must

be compensated for the line pressure. Furthermore, these types of rotameters are absolutely

not leak tight. Air will diffuse into the system, there will also be some permeation through the

material used to build it. There is also a risk that someone tries to control the flow with the

valve mounted on this rotameter (if any). This will be in conflict with the analyzer internal flow

control system.

Problems caused: line pollution, flow instability, reading will be noisy, reading will definitely drift.

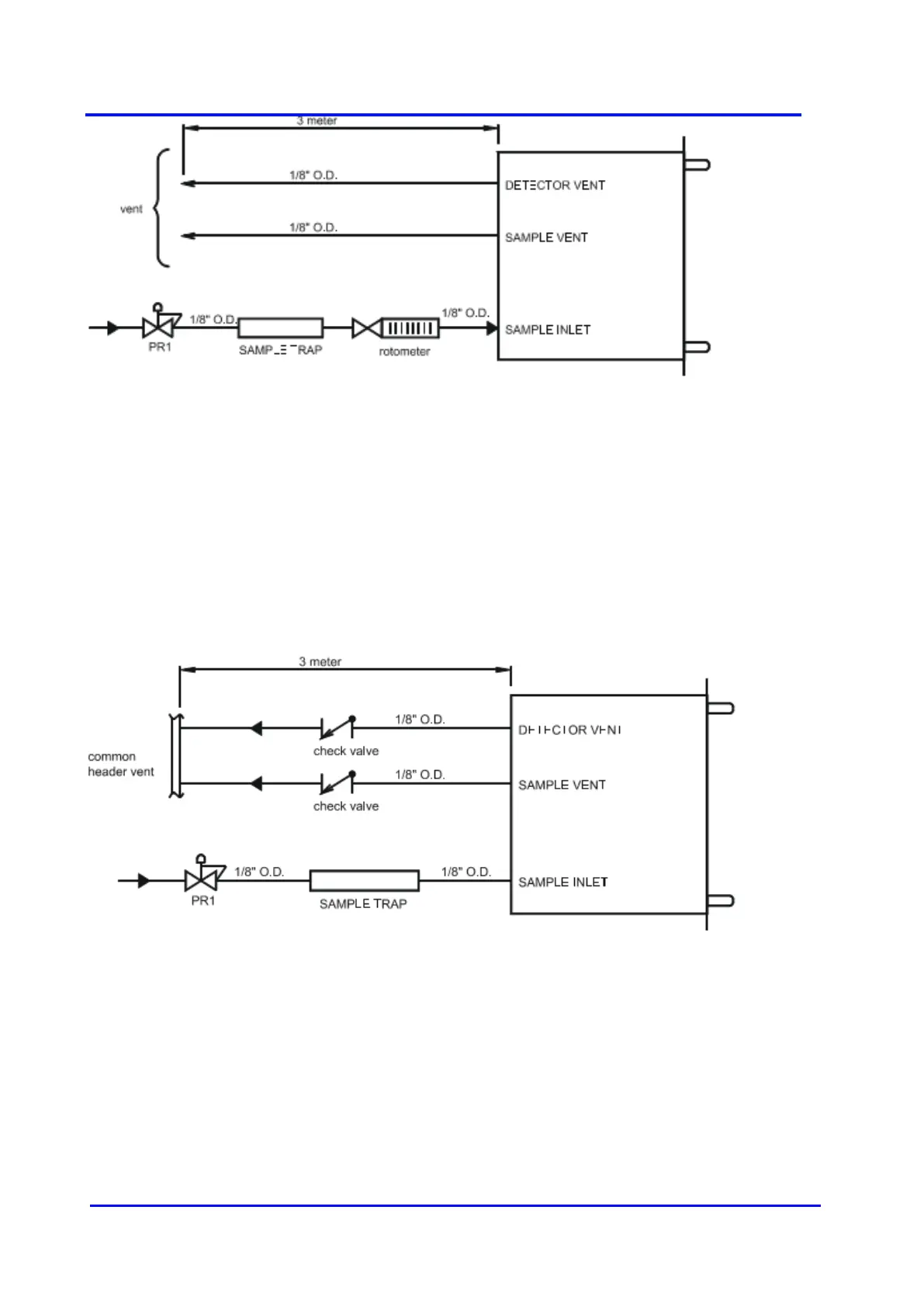

Figure 15 - POOR INSTALLATION EXAMPLE 3

Some users wish to avoid back flow from a vent header into the analyzer vent. Doing so will

cause sample flow and cell pressure variation. The cell pressure will follow header pressure

variation. Check valve cracking pressure is not constant. The plasma cell must work at

atmospheric pressure with no backdraft. Problems caused: noisy signal, risk of cracking the

cell on the event of check valve failure.

Loading...

Loading...