PRODUCT DESCRIPTION 3

8015078/145N/2019-05 -24 | SICK STEGMANN OPERATING INSTRUCTIONS | AFS60/AFM60 PROFINET

13

Subject to change without notice

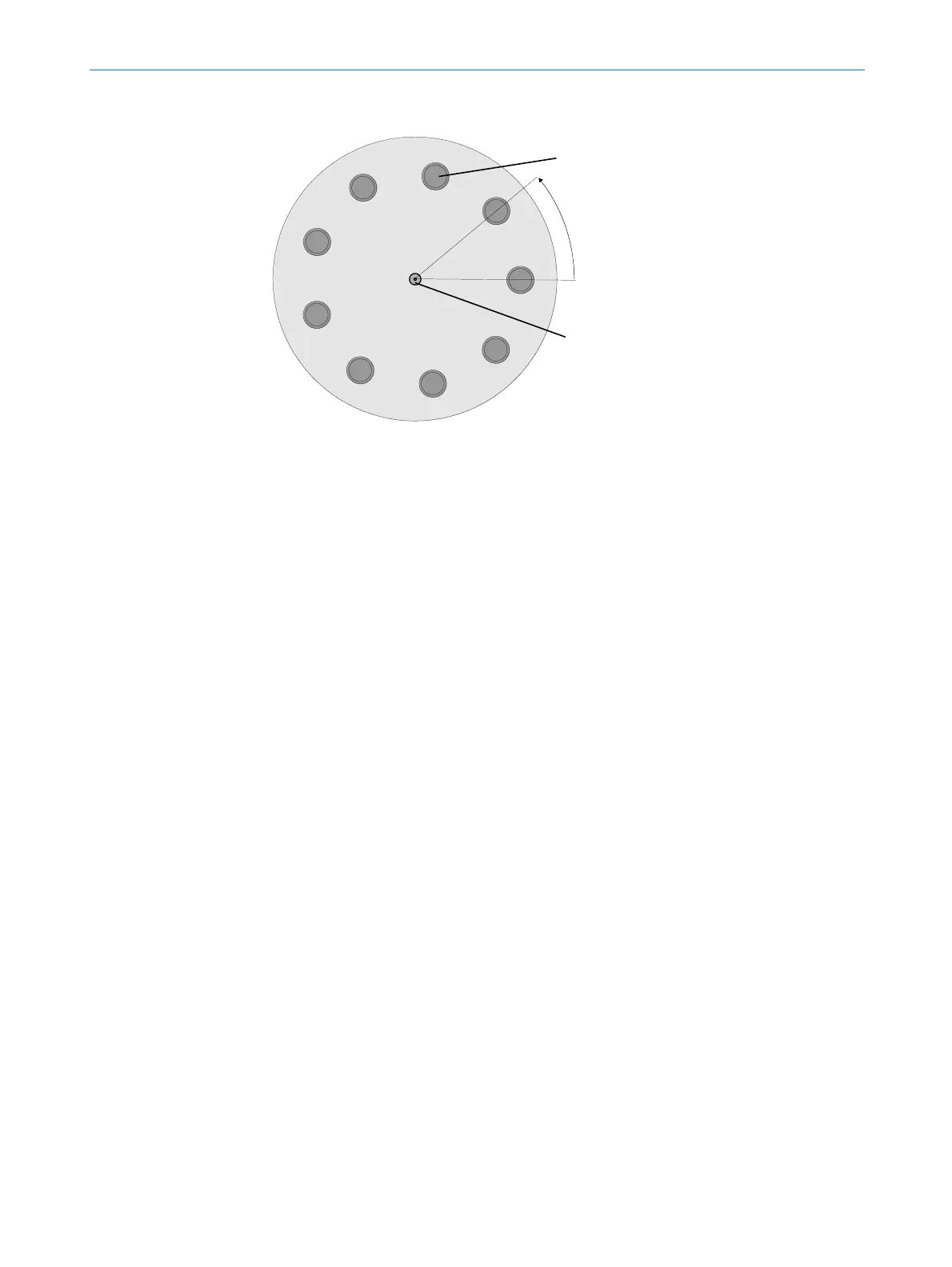

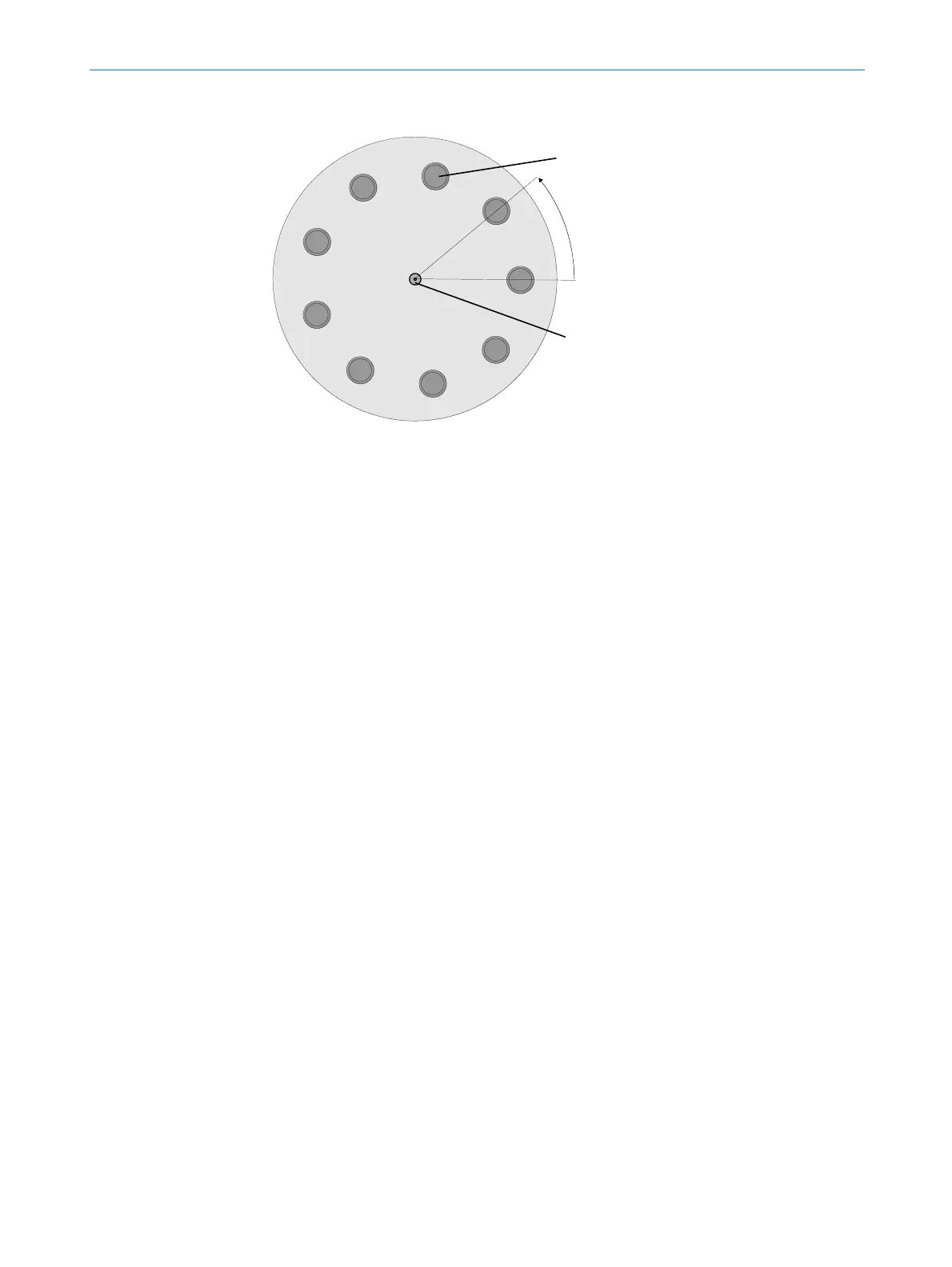

Example without transmission ratio

Figure 2: Example position measurement on a rotary table without transmission ratio

The encoder is mounted directly on the rotary table. The transmission ratio is 1:1.

The rotary table has 9 filling stations. The encoder must be configured such that it

starts to count with 0 at one filling station and counts to 999 on moving to the next

filling station position.

1,000 steps are configured as the total resolution.

For the nominator for the number of revolutions 1 is configured, 9 as the divisor (

1

/9

revolutions = 1,000).

After

1

/9 revolutions of the encoder shaft there are 1,000 steps, then the encoder

starts to count at 0 again.

3.3 Integration in PROFINET

PROFINET is a communication protocol that is based on the open Ethernet standard as

per IEEE 802.3.

PROFINET defines the real-time communication for the fast transmission of process

data.

The AFS60/AFM60 PROFINET is a PROFINET peripheral device and is integrated in a

PROFINET network as a slave.

The encoder is an input/output device. This means that the encoder uses data from

the master on the PROFINET (output data) and also produces data for the PROFINET

itself (input data).

The AFS60/AFM60 PROFINET complies with the guidelines of the encoder profile

version 4.1 class 3 with the encoder profile number 3D00h.

Loading...

Loading...