42 GMS800 · Operating Instructions · 8013025 V1.2 · © SICK MAIHAK GmbH

Adjustment

Subject to change without notice

6.2 Adjustment guideline

6.2.1 How often do you have to adjust?

The GMS800 should be adjusted

● after start-up

● at regular intervals during operation (weekly to monthly).

6.2.2 What do I need for an adjustment?

To perform an adjustment, you need:

● For each measuring component of the GMS800

– suitable zero gas (

→

p. 43, §6.3.1)

– suitable reference gas (

→

p. 44, §6.3.2)

● Time in which normal measuring operation may temporarily stop.

Further prerequisites are:

● Correct test gas parameter settings

[1]

● Correct runtime settings

[1]

The GMS800 can control test gas feed automatically

[1]

.

6.2.3 How can you perform an adjustment?

You can use the following alternative adjustment procedures:

b

Pay primary attention to the adjustment information in the Supplementary

Operating Instructions for the Analyzer Modules fitted.

● Choose larger adjustment intervals when possible (e.g. 3 or 6 months)

when permitted by the application or when expressly allowed (e.g. in a TÜV

approval).

● Specialized measuring systems (e.g. process applications with complex gas

conditioning systems) may need a different adjustment concept.

[1]

→

Technical Information for Control Unit

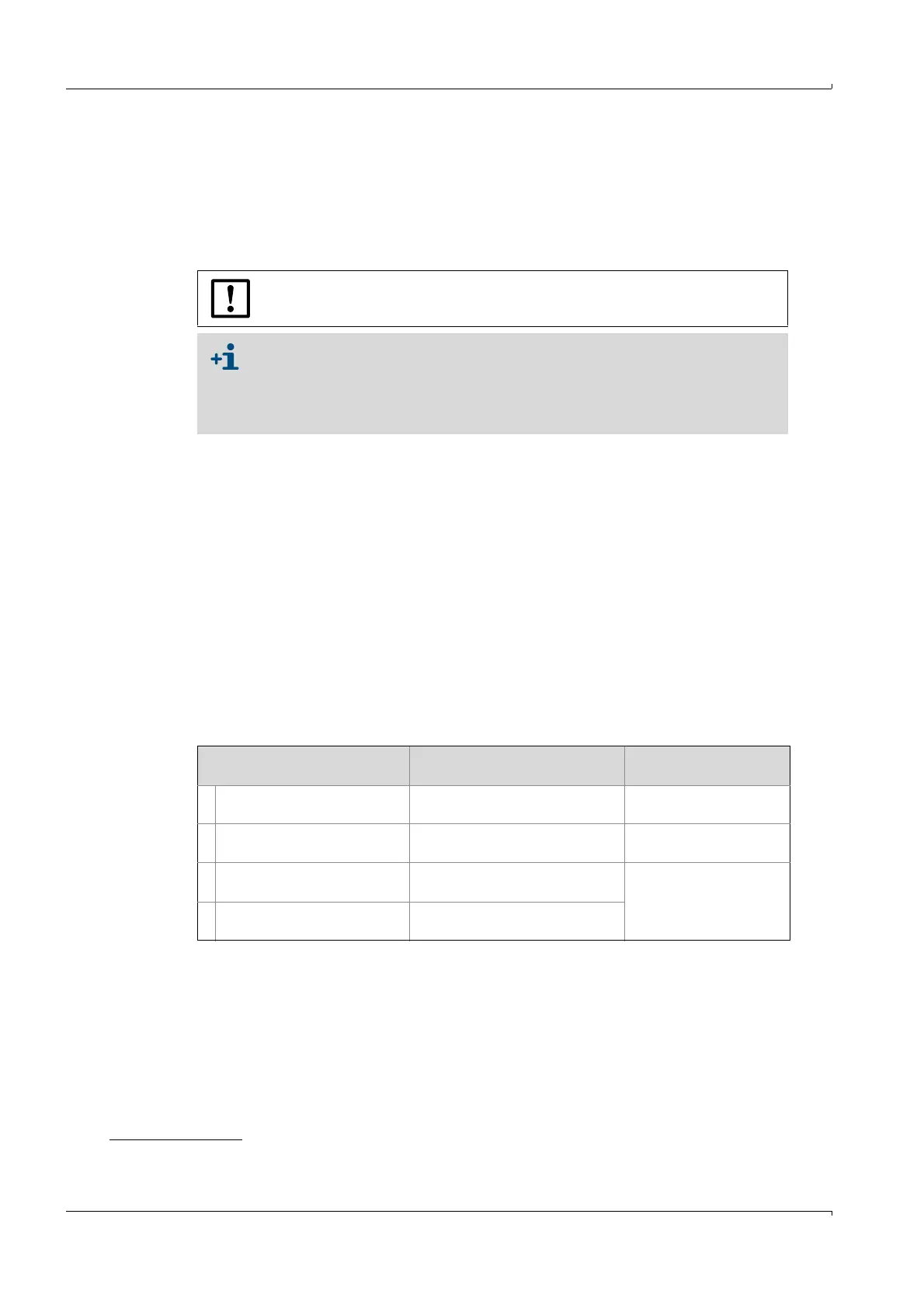

Alternative adjustment proce-

dures

Requirements See

A

Single comparisons with

manual test gas feed

Suitable test gas settings

→

Operating Instruc-

tions for Control Unit

B

Single comparisons with

automatic test gas feed

As in [A] + installations with

automatic test gas feed

→

p. 25, §3.3.6

C

Automatic adjustment

started manually

As in [B] + selection of suitable

sequence control program

→

Technical Infor-

mation for Control Unit

D

Fully automatic (cyclic)

adjustment

As in [C] + programmed cyclic

trigger

Loading...

Loading...