26 FLOWSIC600-XT · Service Manual · 8019179/V0-2/2016-03 · © SICK Engineering GmbH

Repairs

Subject to change without notice

3.4.1.2 Fit the new sensor

1 Unpack the new sensor and check for transport damage. Do not use the sensor when

any damage can be seen at the sensor or the O-ring seal.

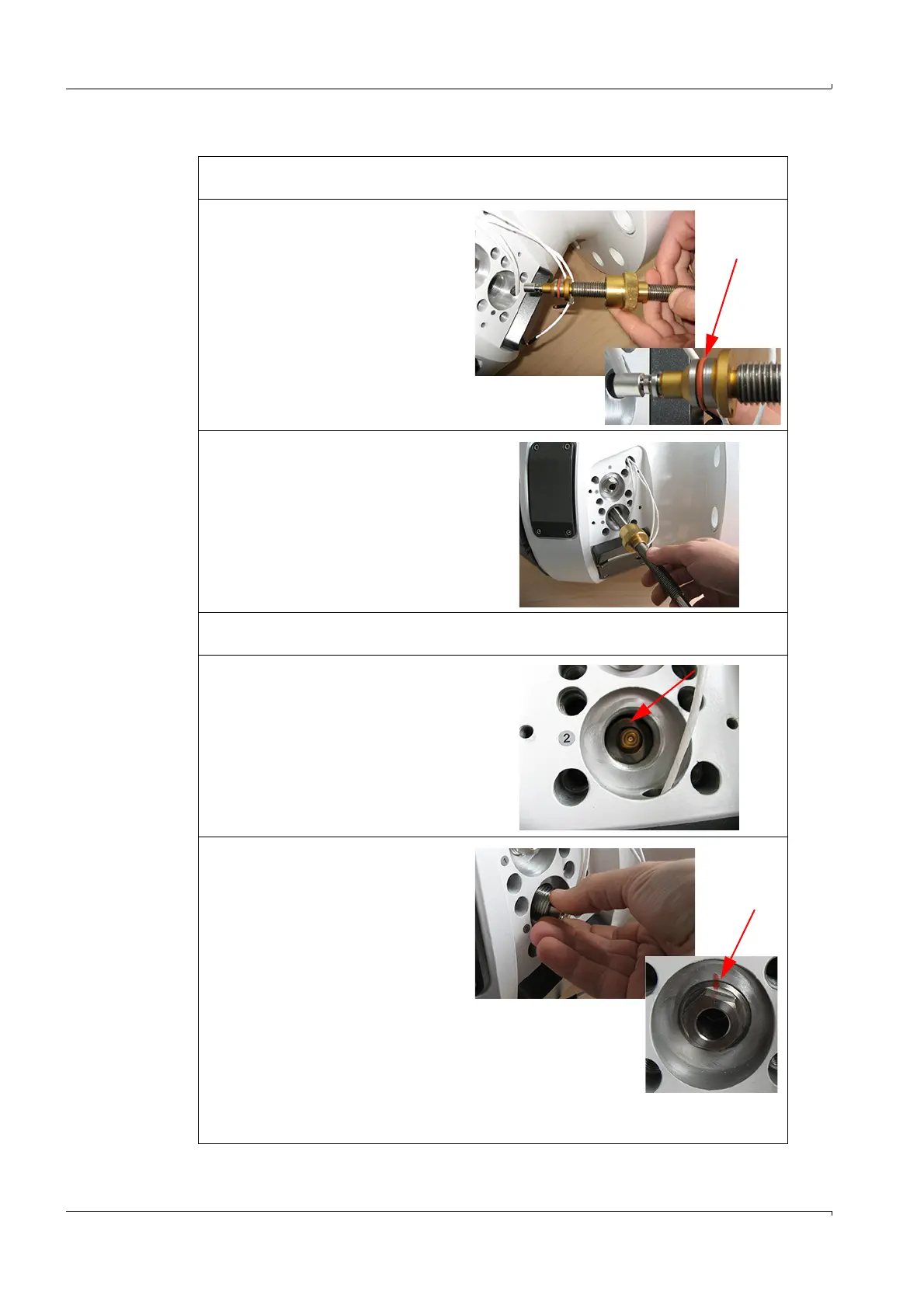

2 Screw the new sensor onto the

assembly tool.

3 Grease the O-ring with lubricant.

Important:

– Do not let lubricant into the area

with media contact.

– Step 3 does not apply to oxygen

applications, do not use lubri-

cant!

4 Insert the sensor into the sensor

support until the resistance of the O-

ring seal can be felt.

5 Fix the sensor carefully with one light

axial circular movement.

Important: The O-ring can be easily

damaged. Only position once and do

not tilt!

6 Unscrew the assembly tool from the sensor. If the sensor turns as well, press the

assembly tool slightly from the top and carefully continue to screw.

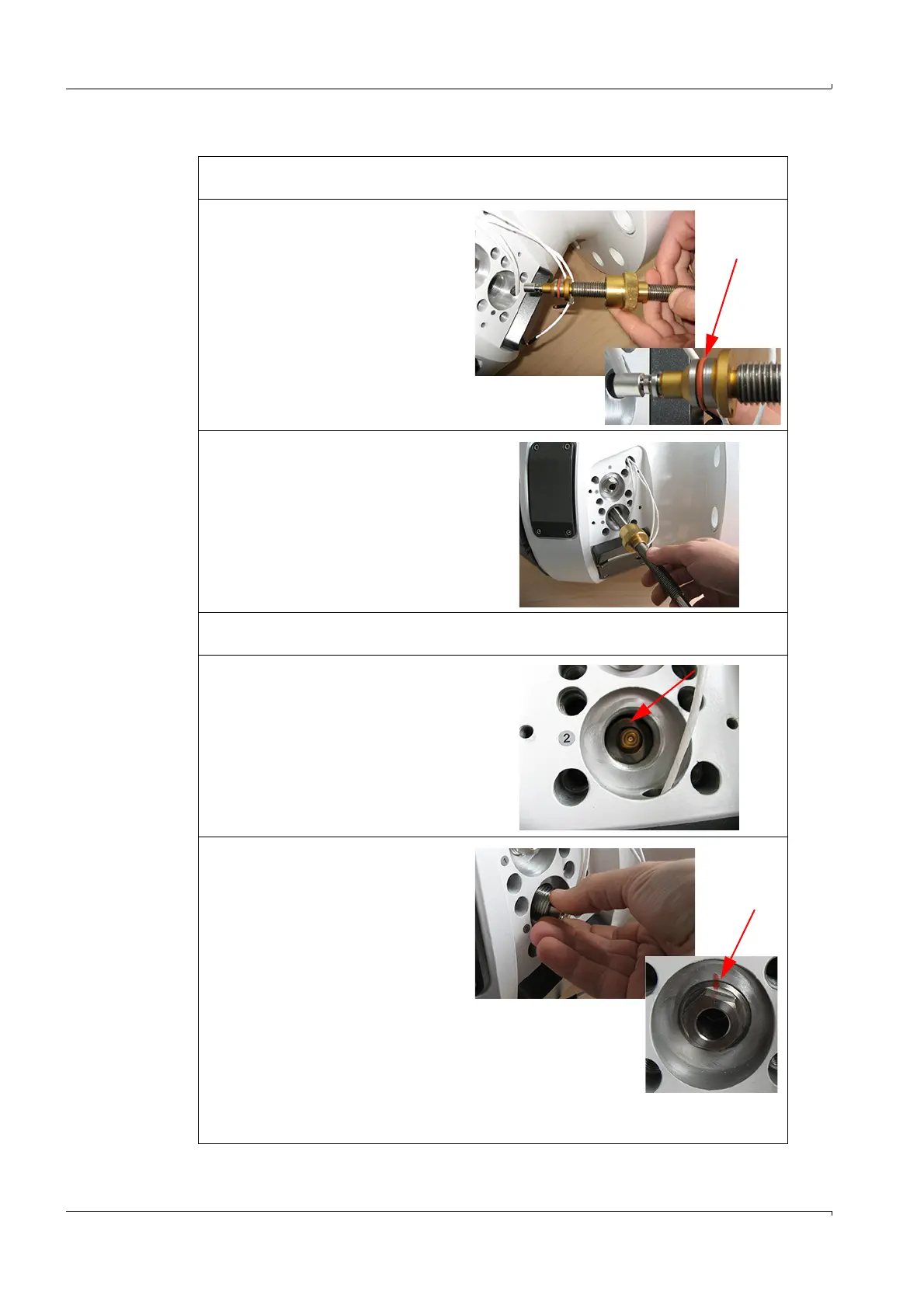

7 Refit the lock washer.

Make sure the washer does not tilt

otherwise the retaining screw cannot

be completely screwed in.

8 Screw the retaining screw in by hand

9 Then tighten with torque 20 Nm.

Check the position of the manufac-

turer's marking:

– The retaining screw has been

screwed in completely when the

markings are aligned.

– If the markings cannot be

aligned, remove the retaining

screw again and check the lock

washer seating.

10 After sensor replacement, perform a

leak tightness check. Apply leak

detection spray to the sensors and

slowly increase the pressure in the device.

Loading...

Loading...