FLOWSIC600 · Operating Instructions · 8010458 V 2.0 · © SICK MAIHAK GmbH 15

Product Description

2.1.2

Ultrasonic transducers

The FLOWSIC600 ultrasonic transducers are optimized to suit the application

requirements. The high quality of the transducer design provides the basis for accurate

and highly stable propagation time measurements with nanosecond precision. These

transducers are of an intrinsically safe design (category “ia“).

2.1.3 Signal processing unit

The SPU contains all the electrical and electronic components for controlling the ultrasonic

transducers. It generates transmission signals and analyzes the received signals to

calculate the measuring values. The SPU also contains several interfaces for

communication with a PC or standardized process control system.

The volume counters, errors, warnings, and system events are stored in a non volatile data

memory (FRAM) together with a time stamp (Logbooks

→

pg.86, 7.2.) On system restart, the

counter readings that were last saved are restored as the start values for the volume

counters. The FRAM backup provides an unlimited number of writing cycles and protects

the saved data for at least 10 years.

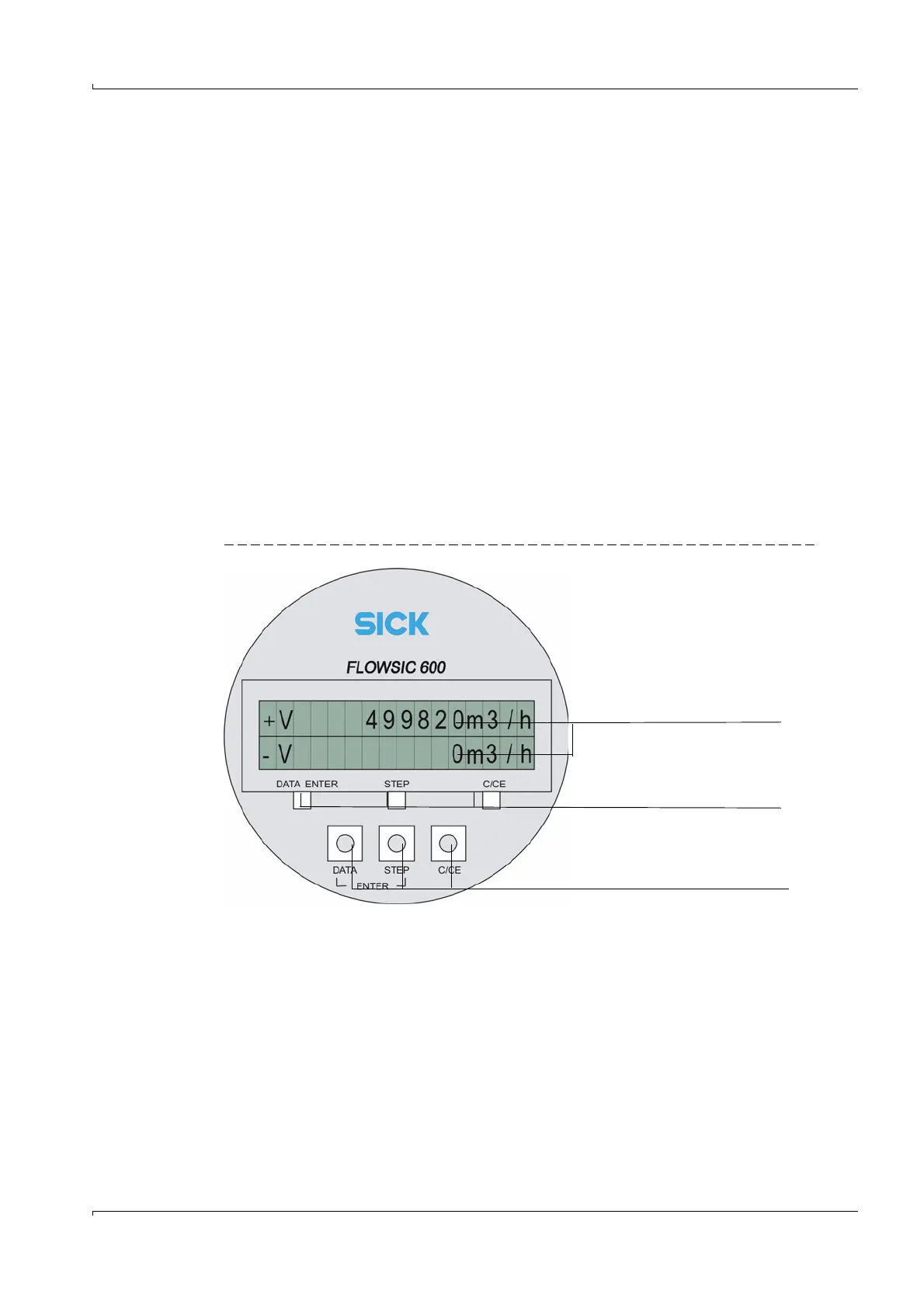

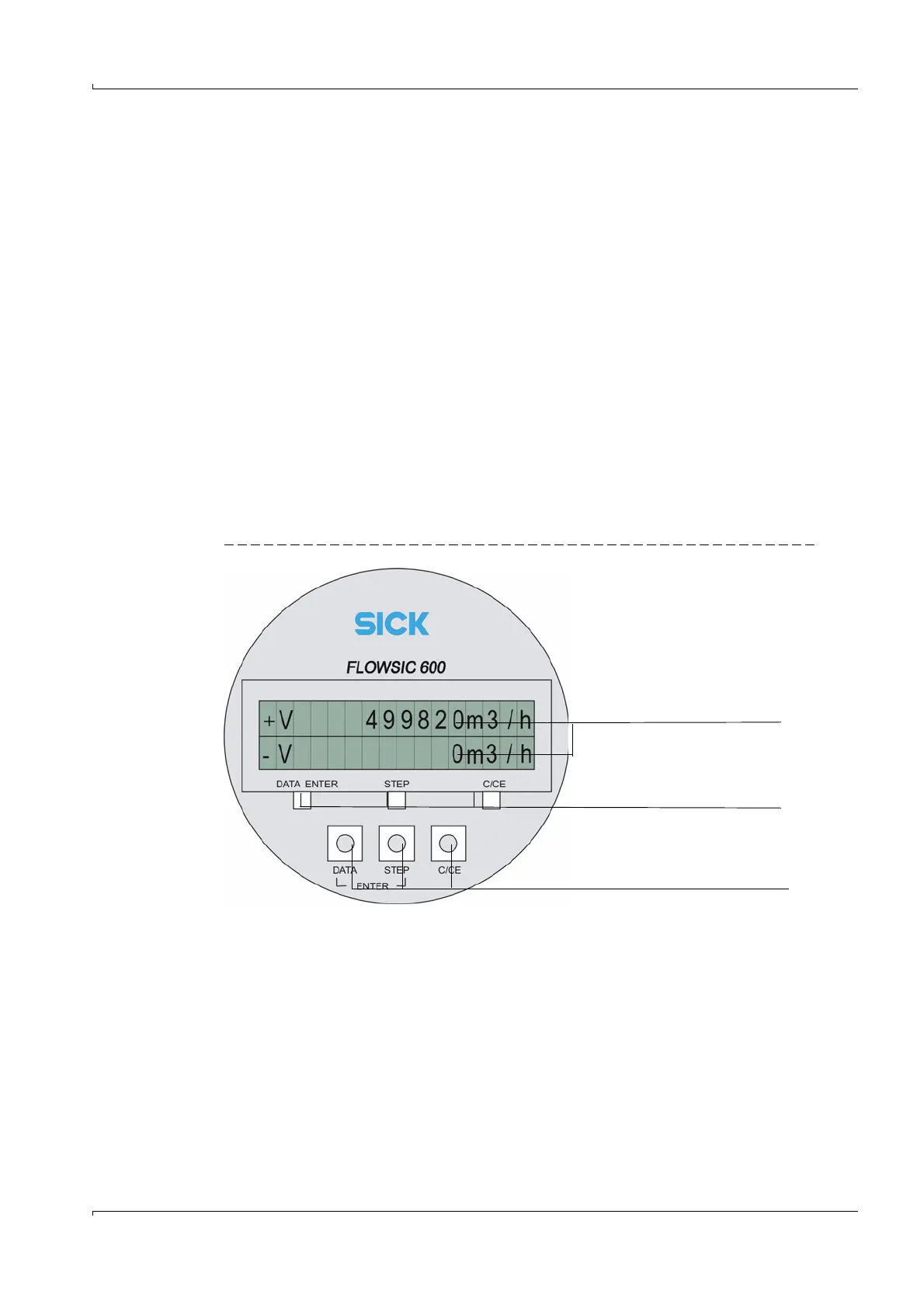

The SPU is equipped with a front panel containing a two-line LCD to display current

measured values, diagnostics and logbook information (

→

Figure 2). The values to be

displayed can be selected using a magnetic pen without removal of the front cover . The

MEPAFLOW600 CBM software provides a more user-friendly way to display the information.

Figure 2 FLOWSIC600 front panel LCD

The power supply and interface terminals are located on the back of the SPU in a separate

terminal section of the enclosure (

→

pg.36, 3.4.4).

The electronics are mounted in the SPU enclosure certified to EN 60079-1 or IEC 60079-1

with protection type “d“ (flameproof enclosure). The transducer circuits are of an

intrinsically safe design (category “ia“).

Measured values

Control buttons for the magnetic pen

Control buttons for manual use

Loading...

Loading...