FLOWSIC600 · Operating Instructions · 8010458 V 2.0 · © SICK MAIHAK GmbH 67

Maintenance

5.3

Maintenance Report

It is recommended to generate and file Maintenance reports on a regular basis. This

serves to create a basis of comparable data over time and helps when a problem has to be

diagnosed.

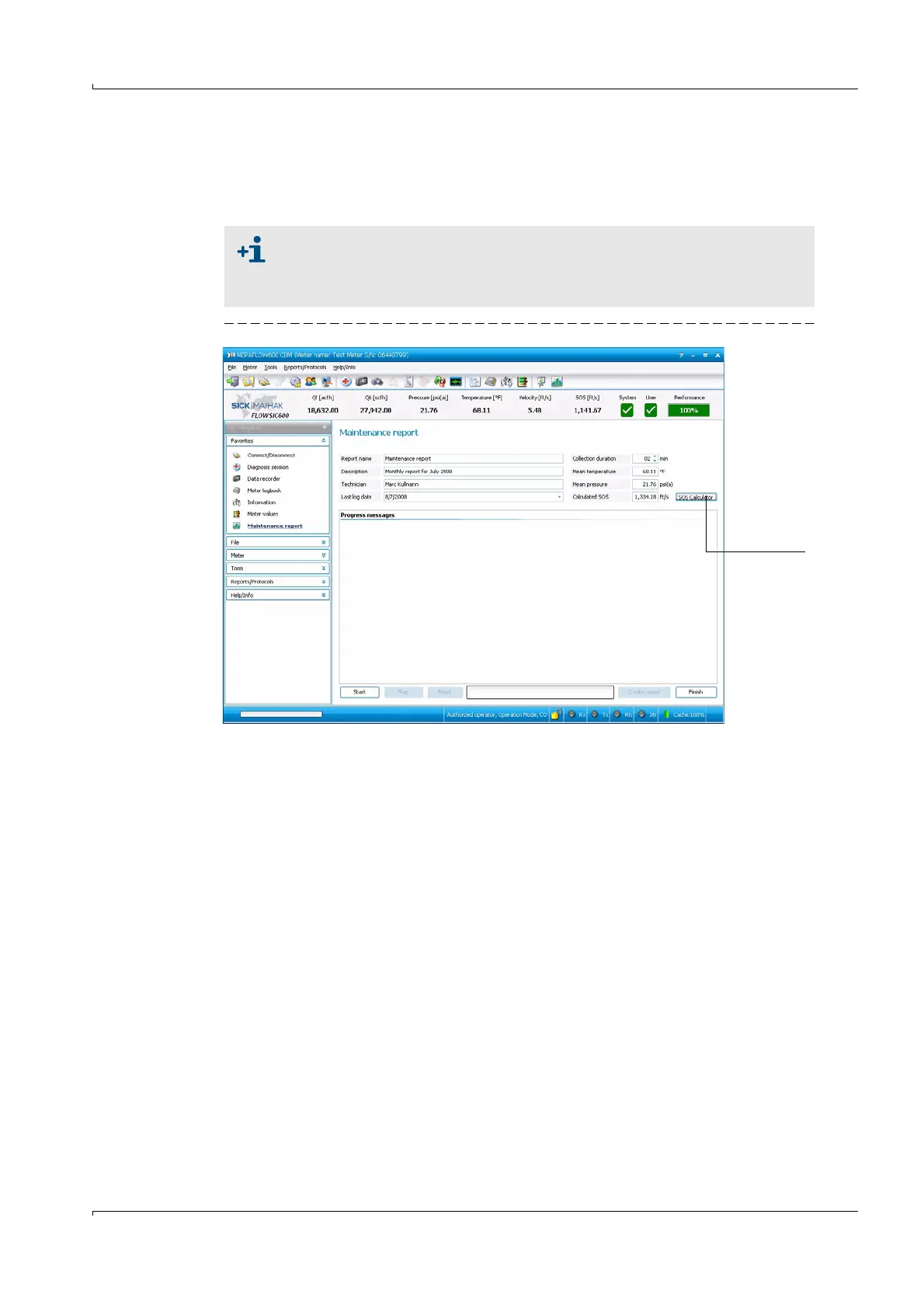

Figure 30 “Maintenance report” wizard

To create a maintenance report, follow the described procedure:

b

Choose “Tools / Maintenance report” from the menu to open the Maintenance report

wizard (

→

Figure 30).

b

Enter the information (Description, Technician) in the fields provided.

b

Specify the collection duration, a timespan, over which live meter data is to be collected

to document the meter‘s state (default: 1 minute).

b

Enter the current pressure, temperature and SOS. Use the SOS Calculator to calculate

the SOS for the gas composition (

→

pg.63, 5.2.1).The gas composition must be current

and representative.

b

Click the “Start” button to start live data collection. Diagnosis data, measured values

and status information will be collected over the specified time span and will be saved

in the meter database

b

Click the “Create report” button. The Maintenance report will be generated and

displayed.

b

Print it and file the copy in the Manufacturer Data Report (MDR) shipped with the

meter. Additionally the data is stored in the MEPAFLOW600 CBM meter database and

accessible via the “Meter explorer” and the “Report manager”. The Maintenance report

can also be exported to Excel using the direct link provided when the Maintenance

report is displayed.

The operating conditions (gas composition, pressure, temperature, flow

velocity) under which the Maintenance reports are created, should be similar.

If the operating conditions are not similar, they should be documented

separately and taken into account when the data is analyzed.

Click to open the

“SOS Calculator”

Loading...

Loading...