FLOWSIC600 · Operating Instructions · 8010458 V 2.0 · © SICK MAIHAK GmbH 63

Maintenance

5.2

Routine Checks

The information displayed on the front panel LCD display of the FLOWSIC600 meter can be

checked to ensure that the system is functioning properly. The MEPAFLOW600 CBM

software provides a more user friendly way for doing routine checks.

5.2.1 Comparing theoretical and measured Speed of Sound (SOS)

One of the most important criteria for the correct operation of an ultrasonic gas meter is

the consistency between the theoretical SOS, calculated for the actual gas composition,

temperature and pressure, and the SOS measured by the ultrasonic gas meter.

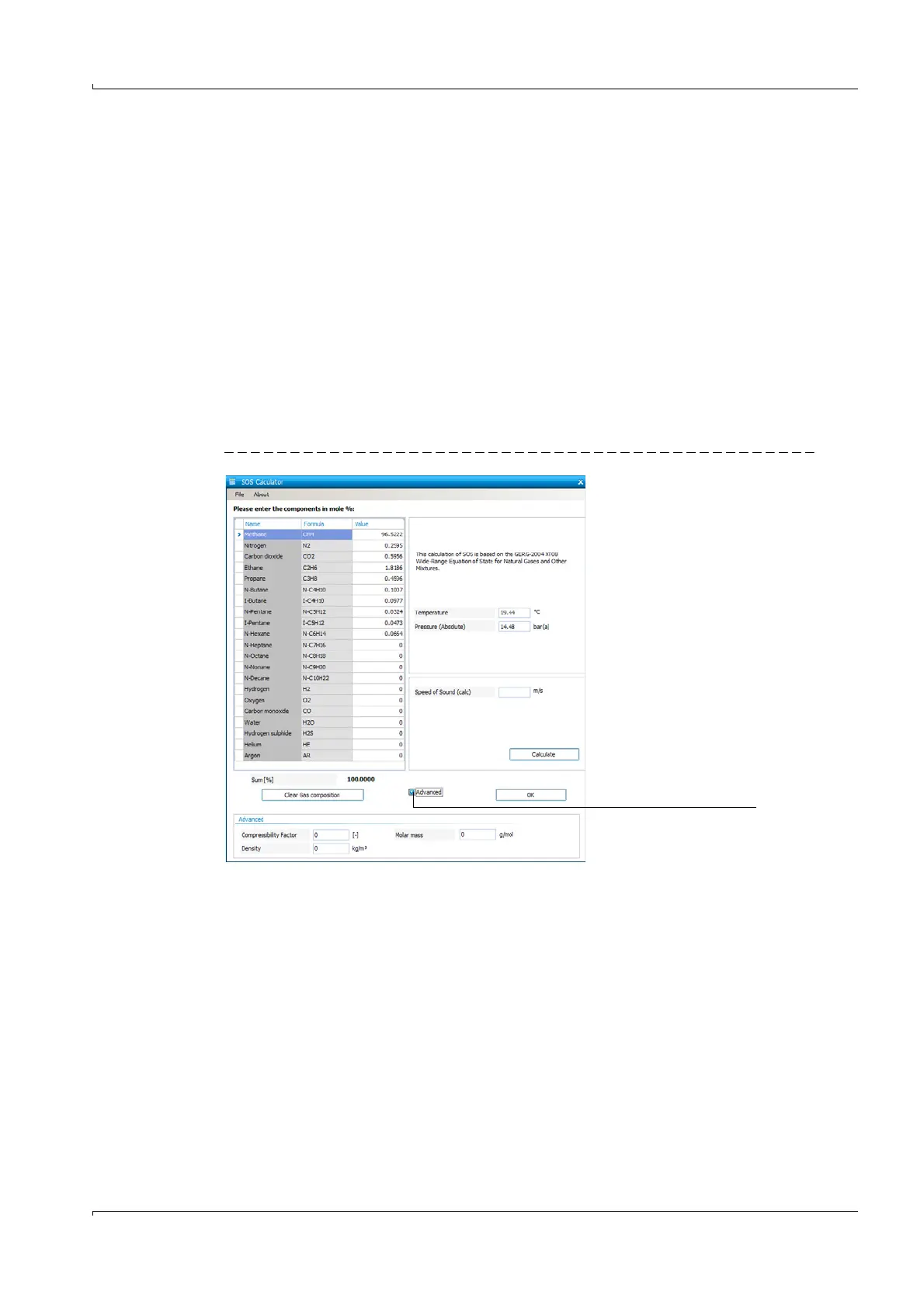

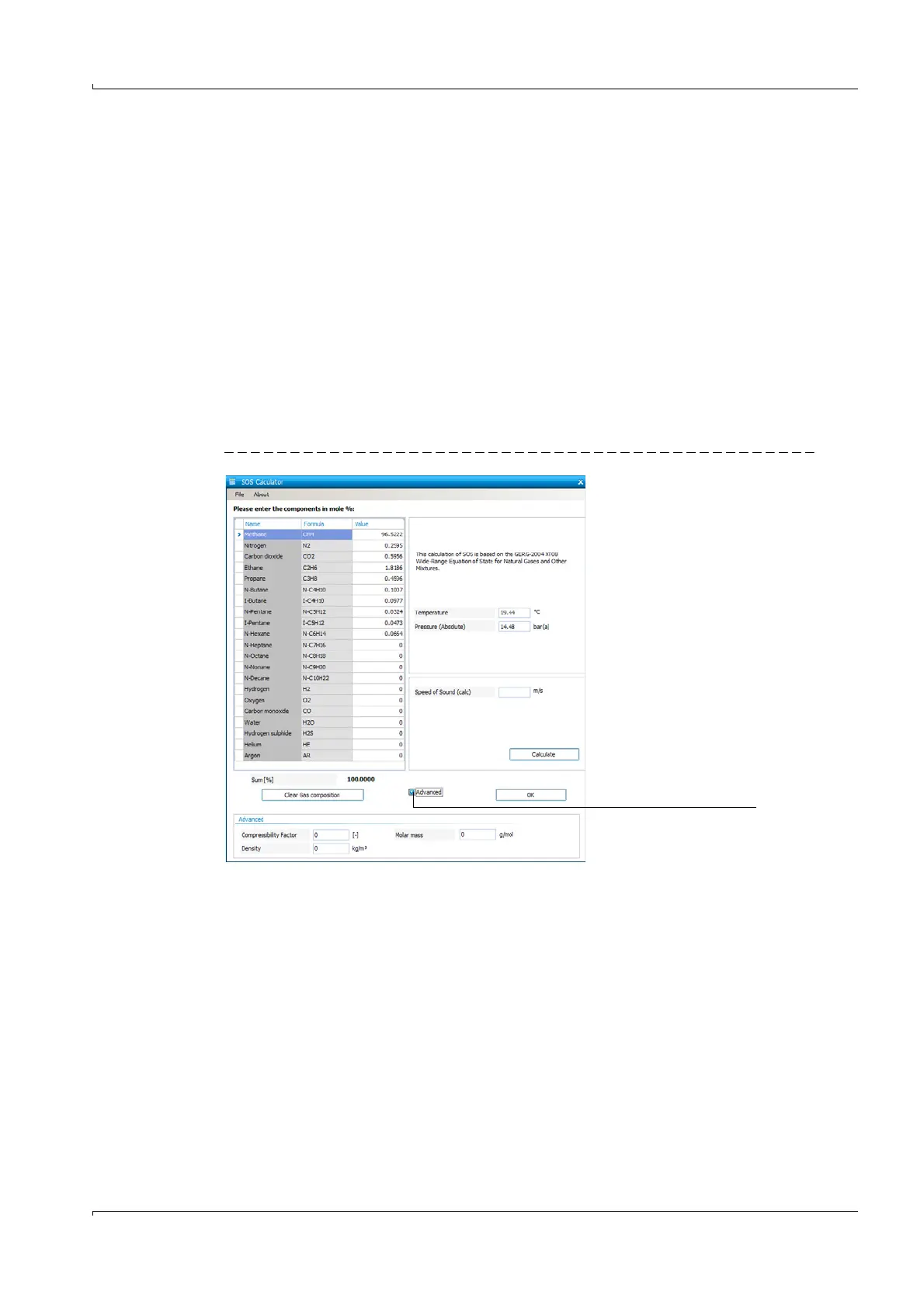

The Speed of Sound Calculator (SOS Calculator) available in MEPAFLOW600 CBM

calculates a theoretical SOS for a specific gas composition at a specified temperature and

pressure (

→

Figure 26). The calculation of thermodynamic properties is based on the “GERG-

2004 Wide-Range Equation of State for Natural Gases and other Mixtures”. The algorithms

that are implemented in the SOS calculator where developed by the Ruhr-University

Bochum (Germany).

Figure 26 Speed of Sound Calculator with loaded gas composition file

b

Use MEPAFLOW600 CBM to connect to your meter (

→

pg.47, 4.3).

b

Start the SOS calculator from the Maintenance report or choose “Tools / SOS

Calculator” from the menu.

b

Enter your gas composition and specify temperature and pressure for your application.

b

For additional settings, activate the “Advanced” checkbox.

b

Click the “Calculate” button.

b

If you started the SOS calculator from the Maintenance Report, the calculated value is

automatically copied to the corresponding field in the wizard and to the report.

b

Compare the theoretical SOS with the SOS measured by the FLOWSIC600 (see Figure 27,

main system bar).

The deviation between both should be less than 0.1%. If the deviation exceeds 0.3%, check

the plausibility of temperature, pressure and gas composition. Else proceed according to

→

pg.63, 5.2.1.

Checkbox for advanced options

Loading...

Loading...