20

8012704/YHS4/V2-0/2016-10 | SICKOPERATING INSTRUCTIONS | GM32

Subject to change without notice

3 PREPARING THE GAS DUCT SIDE

Connections of sender/receiver unit and purge air fixture (see detailed view)

Purge air supply connection

Temperature sensor connection

Purge air/filter monitor connection

CAN line connection: Purge air fixture- reflector (see á)

CAN line connection: Purge air fixture - SR-unit (see â)

Ethernet PC/network connection

Power supply connection

CAN line connection: (see å)

Purge air fixture connection

Table 4: Purge air fixture for sender/receiver unit and purge air fixture

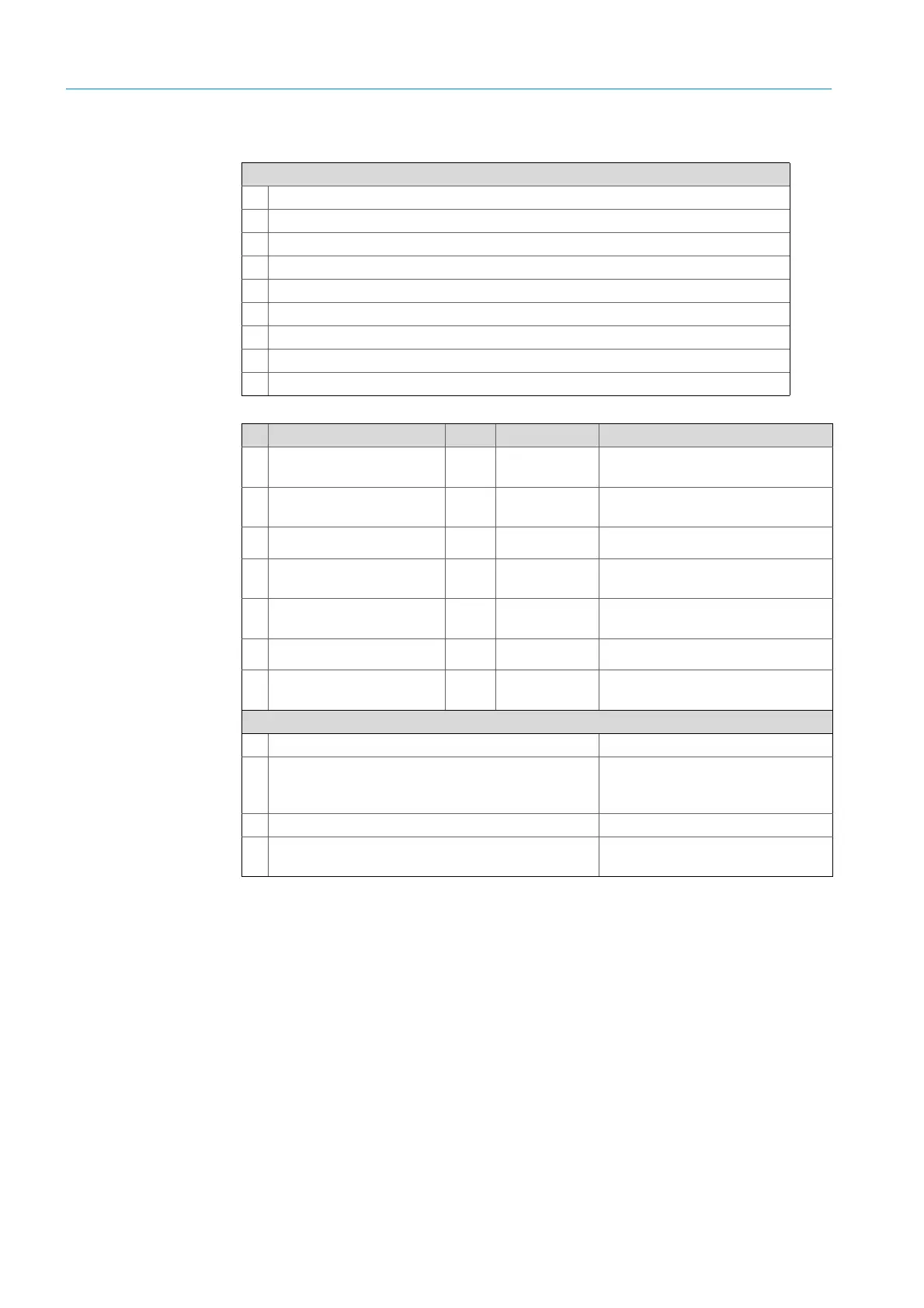

Signal line for connection Length Part number Remark

Purge air fixture - pressure

sensor

à

Purge air fixture - tempera-

ture sensor

á SR – reflector (CAN line)

● 12 m

● 24 m

● 2020861

● 2027031

Order separately

â

SR – purge air fixture

(CAN line)

0.8 m 2023704 Included in the purge air fixture (SR)

ã

Filter monitor 5 m 2032143

Included in the respective purge air fix-

ture (SR + Ref)

ä Power supply SR (standard)

● 10 m

● 20 m

● 2046548

● 2046549

å

CAN line connection unit -

sender/receiver unit

● 10 m

● 20 m

● 2028786

● 2045422

Order separately

On-site lines

a Ethernet – PC/network line

bSCU connection

On-site

Configuration and connections

see “Operating Instructions SCU”

c Power supply 100 ... 240 V AC, 50/60 Hz On-site

d On-site terminal connections (inputs/outputs)

Technical Information “Modular

System I/O”

Table 5: Signal lines

Loading...

Loading...