48

8012704/YHS4/V2-0/2016-10 | SICKOPERATING INSTRUCTIONS | GM32

Subject to change without notice

6 MAINTENANCE

6 Maintenance

6.1 Maintenance plan (operator)

6.1.1 Recommended expendable and wearing parts for 2 years operation

6.2 Preparation work

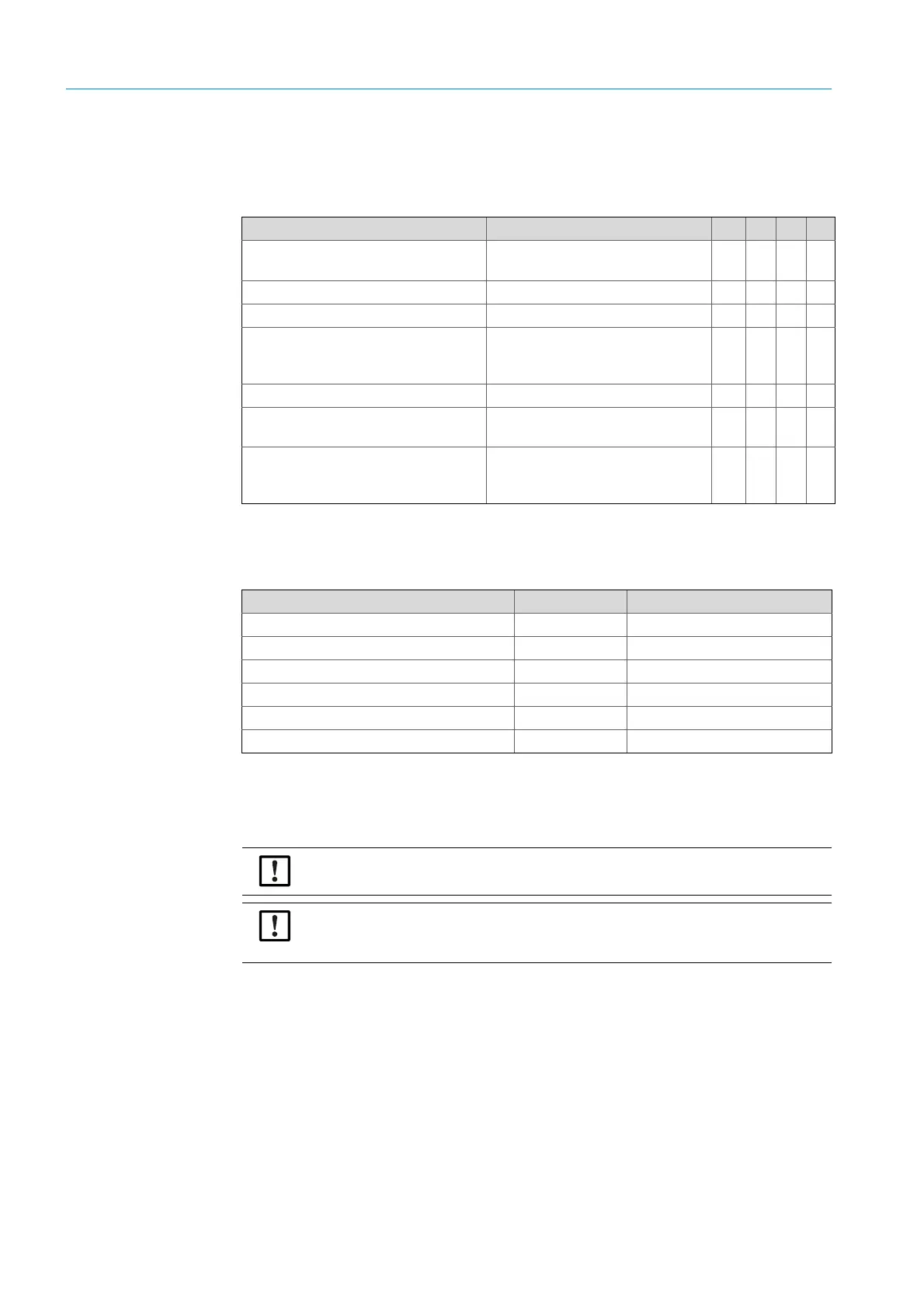

Maintenance task Reference w

[1]

[1] w = weekly, q = quarterly, h = every half year, y = yearly

q

[1]

h

[1]

y

[1]

Checking measured and control values

(zero/test point)

x xxx

Visual inspection see “Visual inspection”, page 50. xxx

Cleaning the window. see “Cleaning the window”, page 50. xxx

Checking the desiccant cartridges,

replace when necessary.

Replace at the latest after 6 months.

see “Checking and replacing the des-

iccant cartridges”, page 50.

xxx

Replacing the activated charcoal bag. SICK Service x

Check the purge air unit.

see “Cleaning the purge air unit”,

page 53.

xxx

Check the optical alignment.

see “Alignment check (automatic

optical alignment check; option)”,

page 45.

xxx

Table 10: Maintenance plan

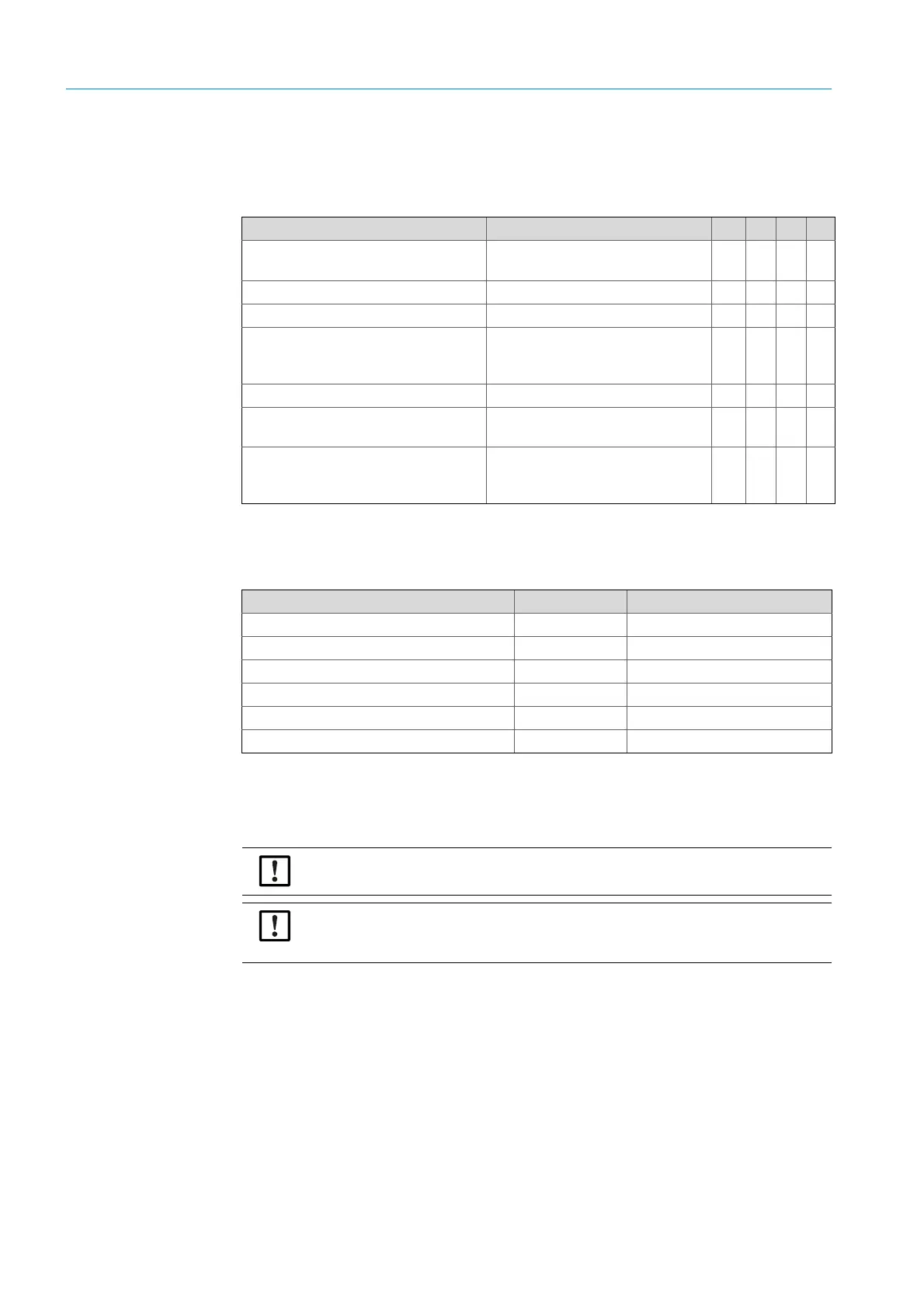

Spare part Number Part No.

[1]

[1] Per piece

Sender lamp 2 pcs 2082776

Sender lamp GM32LN 2 pcs 2086187

Desiccant cartridge 8 pcs 2010549

Activated charcoal bag 2 pcs 5323946

Optical cleaning cloth 8 pcs 4003353

Filter insert for purge air unit 8 pcs 5306091

Table 11: Recommended expendable and wearing parts

NOTE: Some tasks cause the GM32 to switch to malfunction

▸ Activate Maintenance mode before starting work, see “Maintenance”, page 47.

NOTE: Do not switch the purge air off

!▸

Do not disconnect the purge air unit as long as the SR-unit or the reflector is still on

the gas duct.

Loading...

Loading...