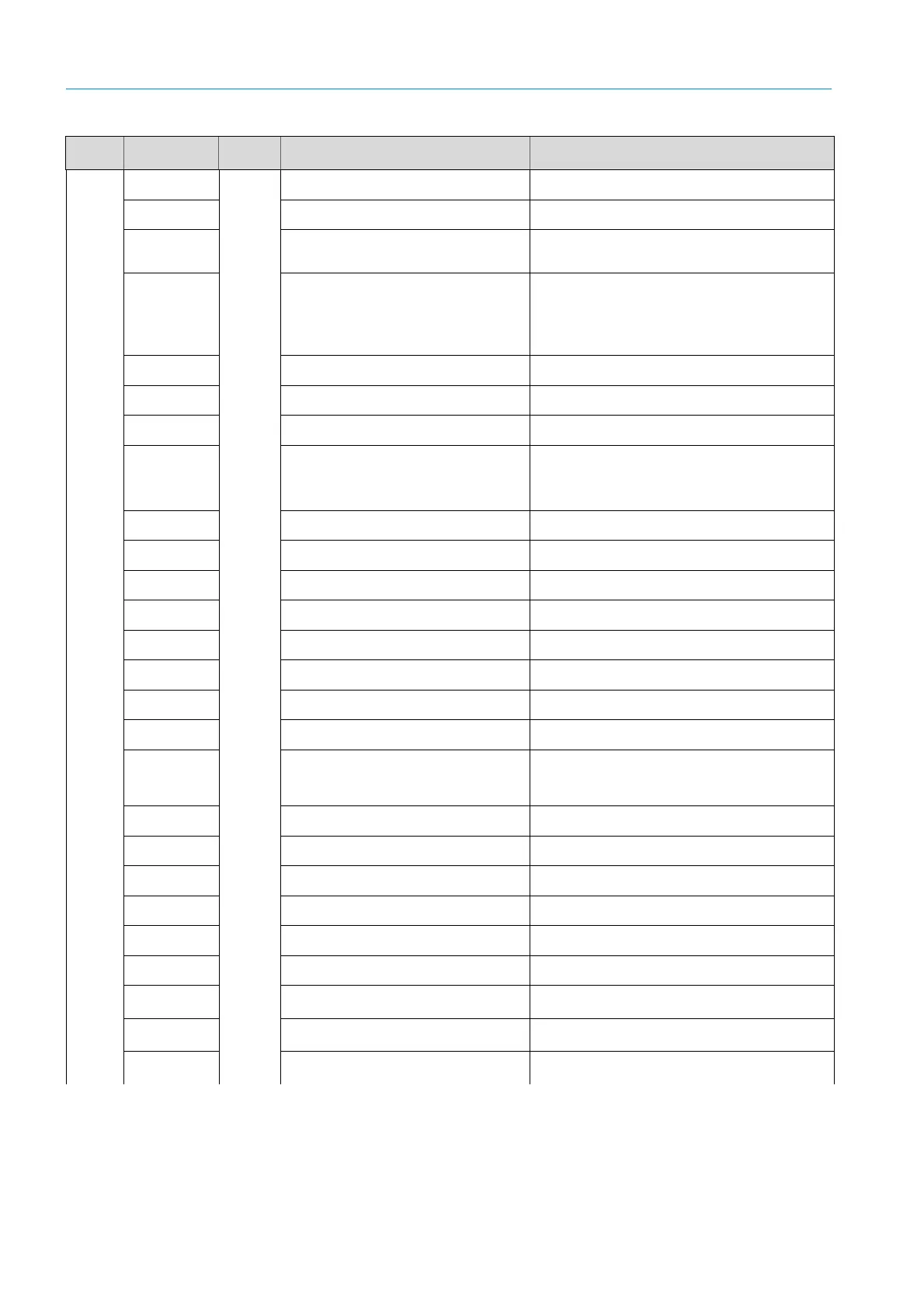

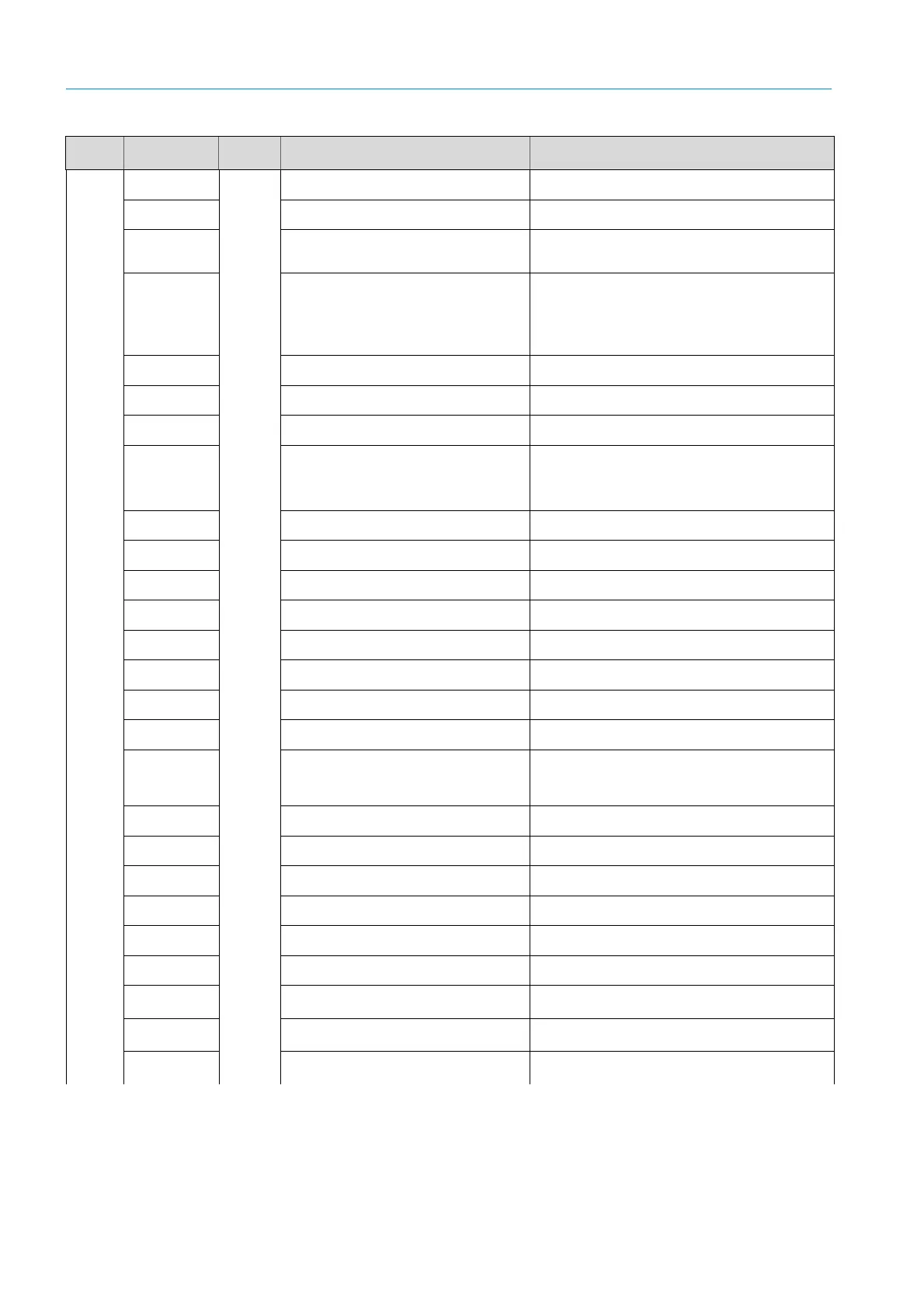

58

8012704/YHS4/V2-0/2016-10 | SICKOPERATING INSTRUCTIONS | GM32

Subject to change without notice

7 CLEARING MALFUNCTIONS

System Lamp perfor-

mance

Mainte-

nance

Warning for lamp performance

Lamp performance <20%

Prepare to exchange the lamp, see “Checking and

replacing the desiccant cartridges”, page 50.

Lamp perfor-

mance limit

Lamp performance too low. Replace lamp, see “Checking and replacing the desic-

cant cartridges”, page 50.

Lamp minimum During lamp adjustment, an excess signal

was determined with minimum lamp current

and exposure.

Check parameter settings.

Lamp 4Q max The lamp current must be set to 1000 mA

(stop) in the alignment procedure.

Alignment, check the optics, see “Alignment check

(automatic optical alignment check; option)”, page

45.

Possible lamp change, see “Checking and replacing

the desiccant cartridges”, page 50, or correct param-

eter settings.

LED perfor-

mance

Lamp performance <20% Replace LED module

LED perfor-

mance limit

Lamp performance near 0% Replace LED module

LED Peltier

error

Peltier element defective (0 A) Replace LED module

LED tempera-

ture mismatch

Nominal temperature of 60°C cannot be

held.

● Can occur during initialization / start phase

(warm-up phase).

● Device temperature too high / too low.

● Replace LED modules

Flashcard miss-

ing

No Flashcard found. Insert the Flashcard, replace a possibly defective card.

IO com. Communication fault to IO block. Connection interrupted, check the cable.

Defective CAN-bus interface.

Spectro no

answer

No data received from spectrometer. Malfunction on the interface to the spectrometer.

Check the plug.

Cycle span drift The measurement on the control filters

showed an excess deviation.

The reference from the adjustment is not correct.

Check limit value parameter setting.

Cycle zero drift The zero point measurement of a measured

value showed an excess deviation.

Check limit value parameter setting.

Cycle wave-

length drift

The check of the current Lambda_C0 coeffi-

cient showed an excess deviation.

Check limit value parameter setting.

Cycle peak posi-

tion

The check of the position of the peak of the

NO cell showed an excess deviation.

Check limit value parameter setting. Defective NO

cell.

Cycle peak

width

The check of the peak width of the NO cell

showed an excess deviation.

Check limit value parameter setting. Defective NO

cell.

Cycle cell empty During the check of the NO cell it is deter-

mined that the highest measured extinction

value in the evaluation range is smaller than

0.1.

Cell is empty.

Temp control

voltage low

The measured voltage supply value is too

small (< 20 V).

Malfunction of temperature control unit.

Temp control

lamp fan

The lamp fan has a malfunction. Malfunction of temperature control unit or fan or

cabling.

Temp control

optic fan

The fan of the optic carrier has a malfunc-

tion.

Malfunction of temperature control unit or fan or

cabling.

Temp control

spectro fan

The fan of the spectrometer has a malfunc-

tion.

Malfunction of temperature control unit or fan or

cabling.

Temp control

electronic temp

The temperature of the temperature control

electronics exceeds 100 °C.

Malfunction of temperature control unit.

Temp control

spectro temp

SR-unit is too warm or too cold. In the heating phase: Normal.

When running: Check ambient temperature.

Data logging:

writing data

Error when writing logging data to the

Flashcard.

Flashcard memory full, Flashcard defective.

Data logging:

open file

Error when opening a file for logging data

on the Flashcard.

Flashcard memory full, Flashcard defective.

System I/O

Error

Error in “Modular I/O System”. Incorrect configuration of I/O module or I/O module

defective.

Initia-

tor

[1]

Text Classifi-

cation

Description Possible causes/remedy

[2]

Table 17 Error messages

Loading...

Loading...