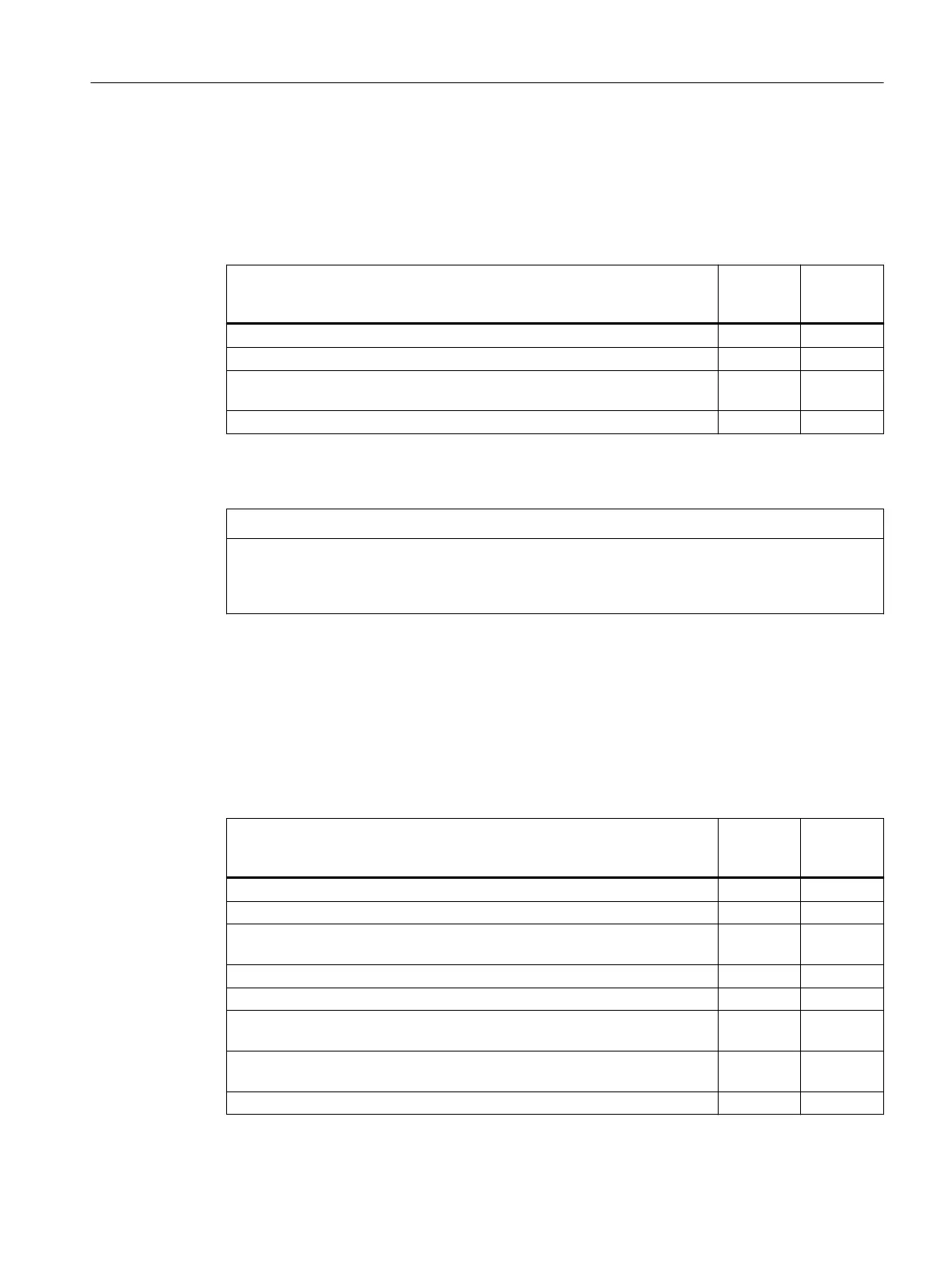

9.2.3 First inspection after installation or repair

Perform the following checks after approximately 500 operating hours or at the latest six

months after commissioning:

Table 9-1 Checks after assembly or repair

Checking When the

motor is

running

At stand‐

still

The electrical parameters are maintained. X

The permissible bearing and winding temperatures are not exceeded. X

The smooth running characteristics and machine running noise have not de‐

teriorated.

X

The foundation has no cracks or indentations. (*) X X

(*) You can perform these checks while the motor is running or at a standstill.

Additional tests may also be required according to the system-specic conditions.

NOTICE

Machine damage

When carrying out the inspection, if you detect any impermissible deviations from the normal

state, you must rectify them immediately. They may otherwise cause damage to the machine.

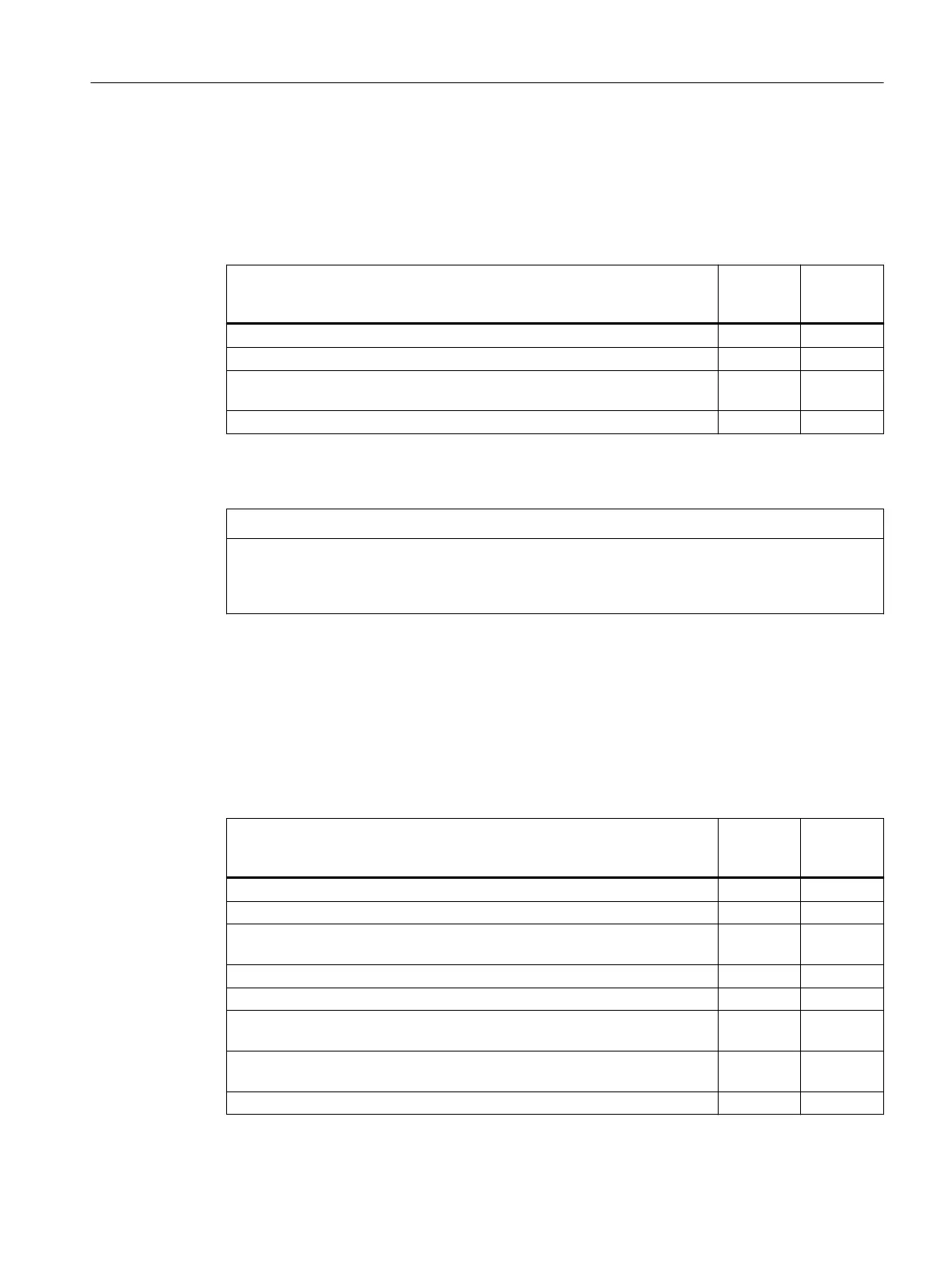

9.2.4 General inspection

Check that the installation conditions are observed. We recommend doing this after approx.

16000 operating hours. Check the following at the latest after 2 years:

Table 9-2 Checks that have to be performed during the general inspection

Checking When the

motor is

running

At stand‐

still

The electrical parameters are maintained. X

The permissible bearing temperatures are not exceeded. X

The smooth running characteristics and machine running noise have not de‐

teriorated.

X

The foundation has no cracks or indentations. (*) X X

The machine is aligned within the permissible tolerance ranges X

All the xing bolts/screws for the mechanical and electrical connections have

been securely tightened

X

All the potential connections, grounding connections and shield supports are

correctly seated and properly bonded

X

The winding insulation resistances are suciently high X

Maintenance

9.2Inspection and maintenance

1MB..1/2/3/4 - shaft heights 63 ... 355

Operating Instructions, 11/2023, A5E52779900A 119

Loading...

Loading...