6.5.4 Minimum air clearances

After proper installation, verify that the minimum air clearances between non-insulated parts

are maintained. Be aware of any protruding wire ends.

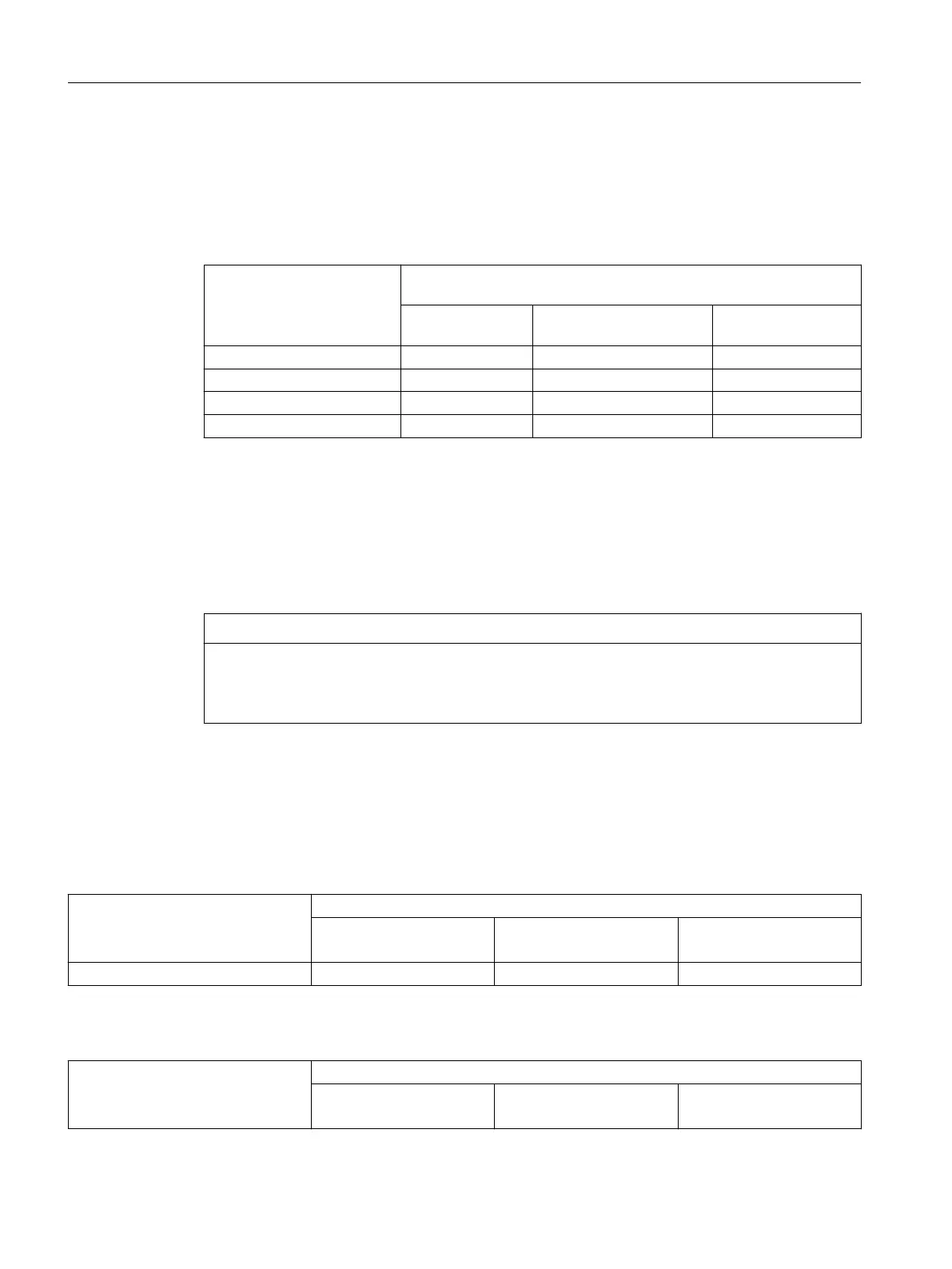

Table 6-4 Minimum air clearance dependent on rms value of the alternating voltage U

rms

Rms value of the alternat‐

ing voltage U

rms

Minimum air clearance

mm

Ex tc

Ex tb

Ex nA

Ex ec

Ex e

Ex eb

≤250V 3.0 2.5 5.0

≤500V 3.0 5.0 8.0

≤630V 5.5 5.5 10.0

≤1000V 8.0 8.0 14.0

Values apply at an installation altitude of up to 2000m.

When determining the required minimum air clearance, the voltage value in the table may be increased by

a factor of 1.1, so that the rated input voltage range is taken into account during general use.

6.6 Connecting the converter

NOTICE

Material damage caused by an excessively high supply voltage

Material damage can occur if the supply voltage is too high for the insulation system.

• Observe the values in the following tables.

SIMOTICS machines can be operated with SINAMICS converters (uncontrolled and controlled

infeed) when maintaining the permissible voltage peaks.

The insulation system of SIMOTICS machines corresponds to the specications laid down in

IEC 60034-18-41 according to voltage stress category C (IVIC C = high stress).

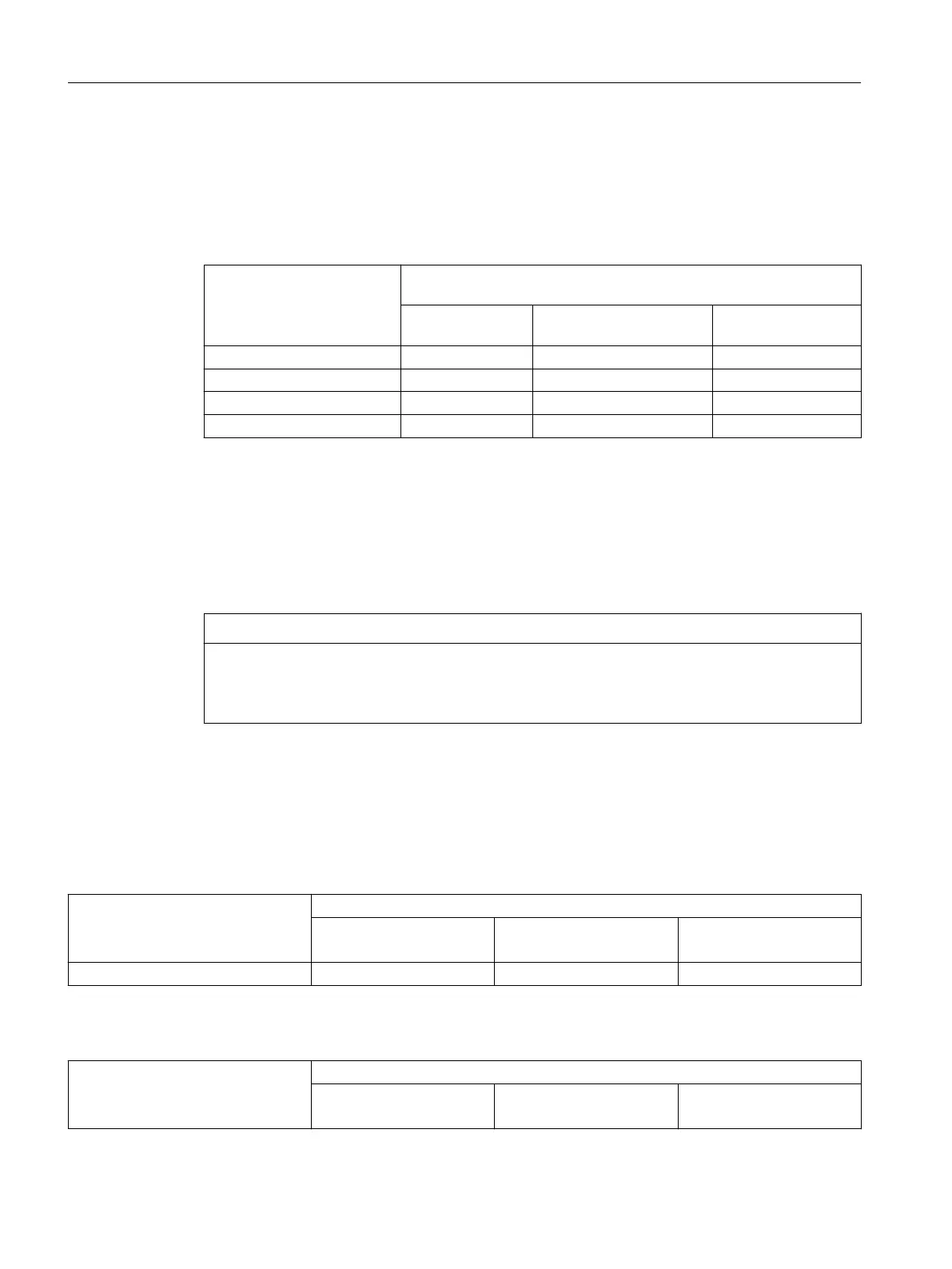

Table 6-5 Maximum voltage peaks at the motor terminals for line (DOL) motors, converter operation possible

Rated motor voltage

V

Maximum peak voltage at the motor terminals

Û

phase-to-phase

V

pk

Û

phase-to-ground

V

pk

DC link U

DC

V

≤ 500V 1500 1100 750

Table 6-6 Maximum voltage peaks at the motor terminals for motors specically designed for converter operation

Rated motor voltage

V

Maximum peak voltage at the motor terminals

Û

phase-to-phase

V

pk

Û

phase-to-ground

V

pk

DC link U

DC

V

Electrical connection

6.6Connecting the converter

1MB..1/2/3/4 - shaft heights 63 ... 355

92 Operating Instructions, 11/2023, A5E52779900A

Loading...

Loading...