The machines are equipped with permanently lubricated rolling bearings. The machine may

be equipped with a regreasing device.

CAUTION

Skin irritations and eye inammations

Many greases can cause skin irritations and eye inammations.

• Follow all safety instructions of the manufacturer.

Measures, intervals and deadlines

Measures after operating period intervals or deadlines have elapsed:

Operating situations and characteristics can vary widely. For this reason, only general

maintenance intervals are specied here. Maintenance intervals should therefore be

scheduled to suit the local conditions (dirt, starting frequency, load, etc.).

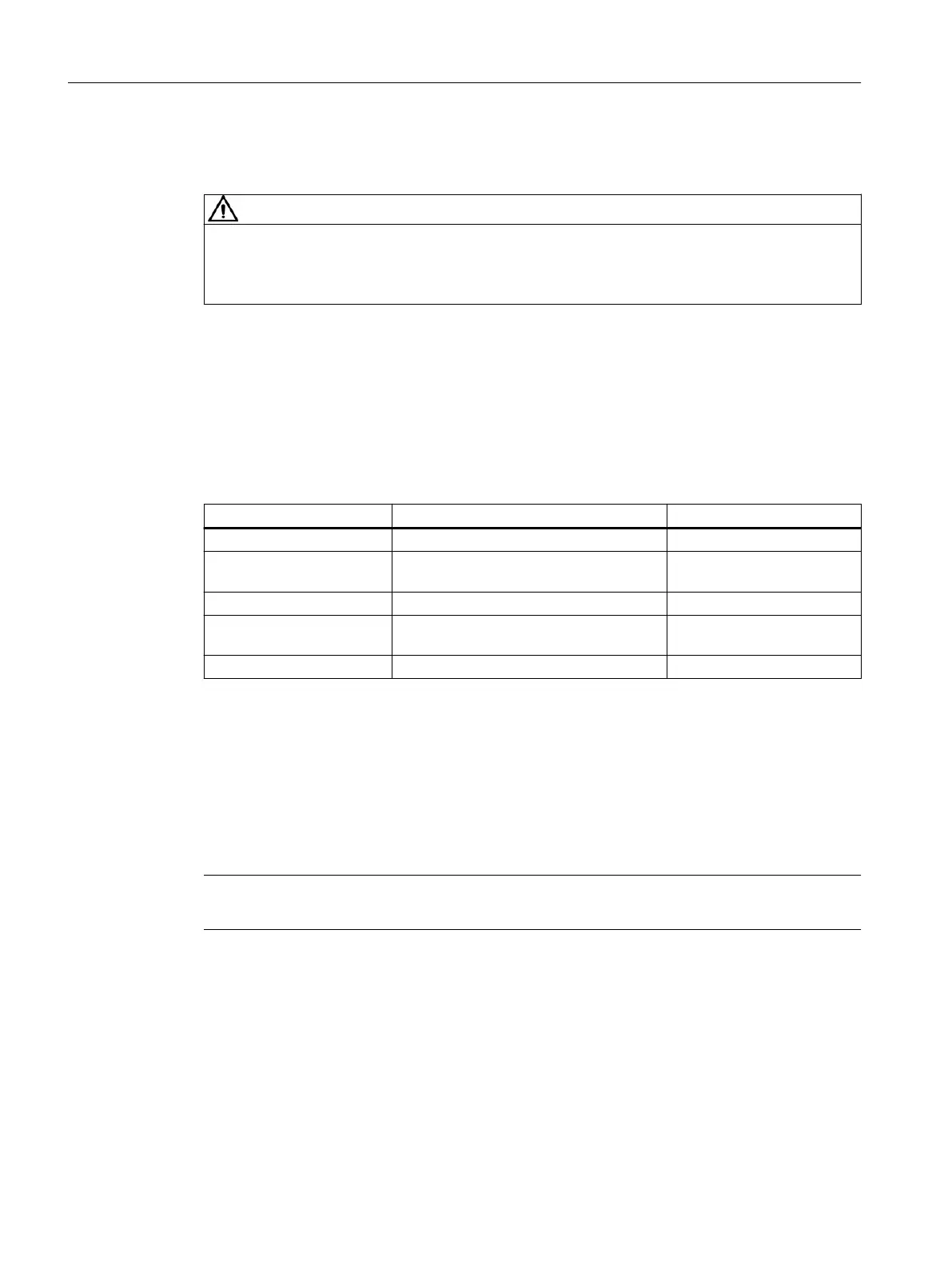

Table 9-3 Operating period intervals

Measures Operating period intervals Intervals

Initial inspection After 500 operating hours After 1/2 year at the latest

Relubrication (optional) Refer to the lubrication plate or the rating

plate

Clean Depending on the degree of pollution

Main inspection Approximately every 16000 operating

hours

After two years at the latest

Drain condensate Depending on the climatic conditions

9.2.8 Re-greasing

For machines with regreasing system, relubrication intervals, grease quantity and grease grade

are provided on the lubricant plate. Additional data can be taken from the main machine rating

plate.

Grade of grease for standard motors (IP55) UNIREX N3 - ESSO.

Note

It is not permissible to mix dierent types of grease.

Prolonged storage periods reduce the useful lifetime of the bearing grease. Check the

condition of the grease if the equipment has been in storage for more than 12 months.

If the grease is found to have lost oil content or to be contaminated, the machine must

be immediately relubricated before commissioning. For information on permanently-greased

bearings, please refer to the section titled Rolling bearings (Page129).

Maintenance

9.2Inspection and maintenance

1MB..1/2/3/4 - shaft heights 63 ... 355

122 Operating Instructions, 11/2023, A5E52779900A

Loading...

Loading...