CAUTION

Damage to connecting cables that are freely led out

You must observe the following note to avoid damaging connecting cables that are freely led

out:

• It must be ensured that there are no foreign bodies, dirt, or moisture in the terminal base

of the machine enclosure.

• Use O-rings or suitable at gaskets to seal entries in cover plates (DIN 42925) and other

open entries.

• Seal the terminal base of the machine enclosure using the original seal of the cover plate to

prevent dust and water from entering.

• Please observe the tightening torques for cable entries and other screws.

6.1.4.7 Connecting protruding cables

In the case of connection cables brought out of the machine, no terminal board is installed on

the terminal base of the machine housing. The connection cables are directly connected to

stator winding terminals at the factory.

The connection cables are color-coded or labeled. The customer directly connects individual

cables in the control cabinet for their system in accordance with the labeling.

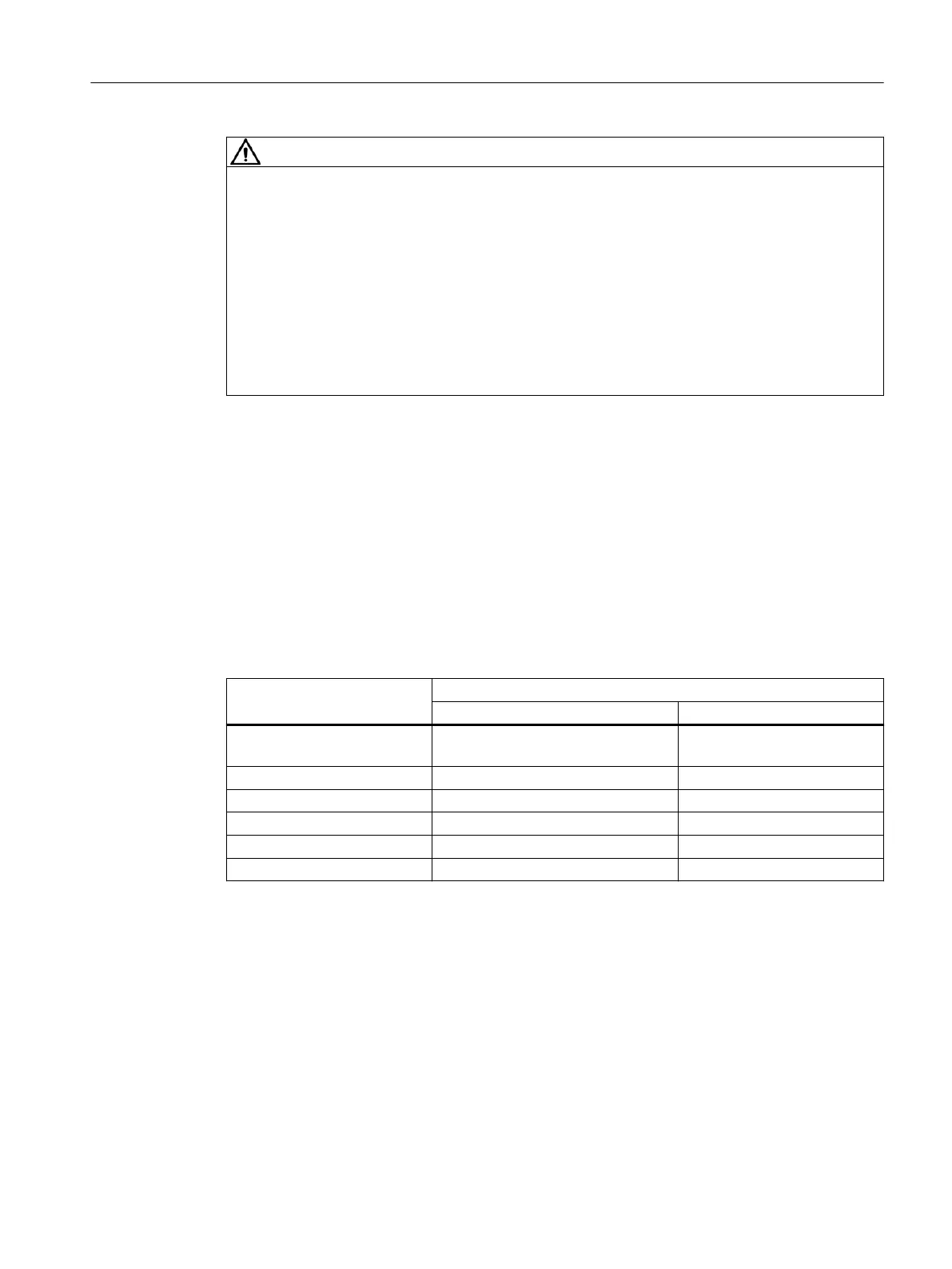

6.1.4.8 Thread sizes in the terminal box

Shaft height Threaded entry

Size Quantity

63 ... 90 M16x1.5

M25x1.5

1

100 ... 132 M32x1.5 2

160 ... 180 M40x1.5 2

200 ... 225 M50x1.5 2

250 ... 315 M63x1.5 2

355 M80x2 2

Thread size for additional glands, e.g. PTC thermistor or anti-condensation heating M16x1.5

or M20x1.5

Deviating thread sizes are specied at the motor.

6.1.4.9 Internal equipotential bonding

The internal equipotential bonding between the grounding terminal in the terminal box, the

terminal box components and the machine enclosure is ensured via metallic contact, a copper

braided strip or a stranded wire.

Electrical connection

6.1Connecting the machine

1MB..1/2/3/4 - shaft heights 63 ... 355

Operating Instructions, 11/2023, A5E52779900A 83

Loading...

Loading...