• Do not reuse bearings that have been removed.

• Remove the dirty spent grease from the bearing shield.

• Replace the existing grease with new grease.

• Replace the shaft seals when the bearings are replaced.

• Slightly grease the contact surfaces of the sealing lips.

Note

Special operating conditions

The operating hours are reduced, e.g.

• When machines are vertically mounted.

• High vibration and surge loads

• Frequent reversing operation

• Higher ambient temperatures.

• High speeds etc.

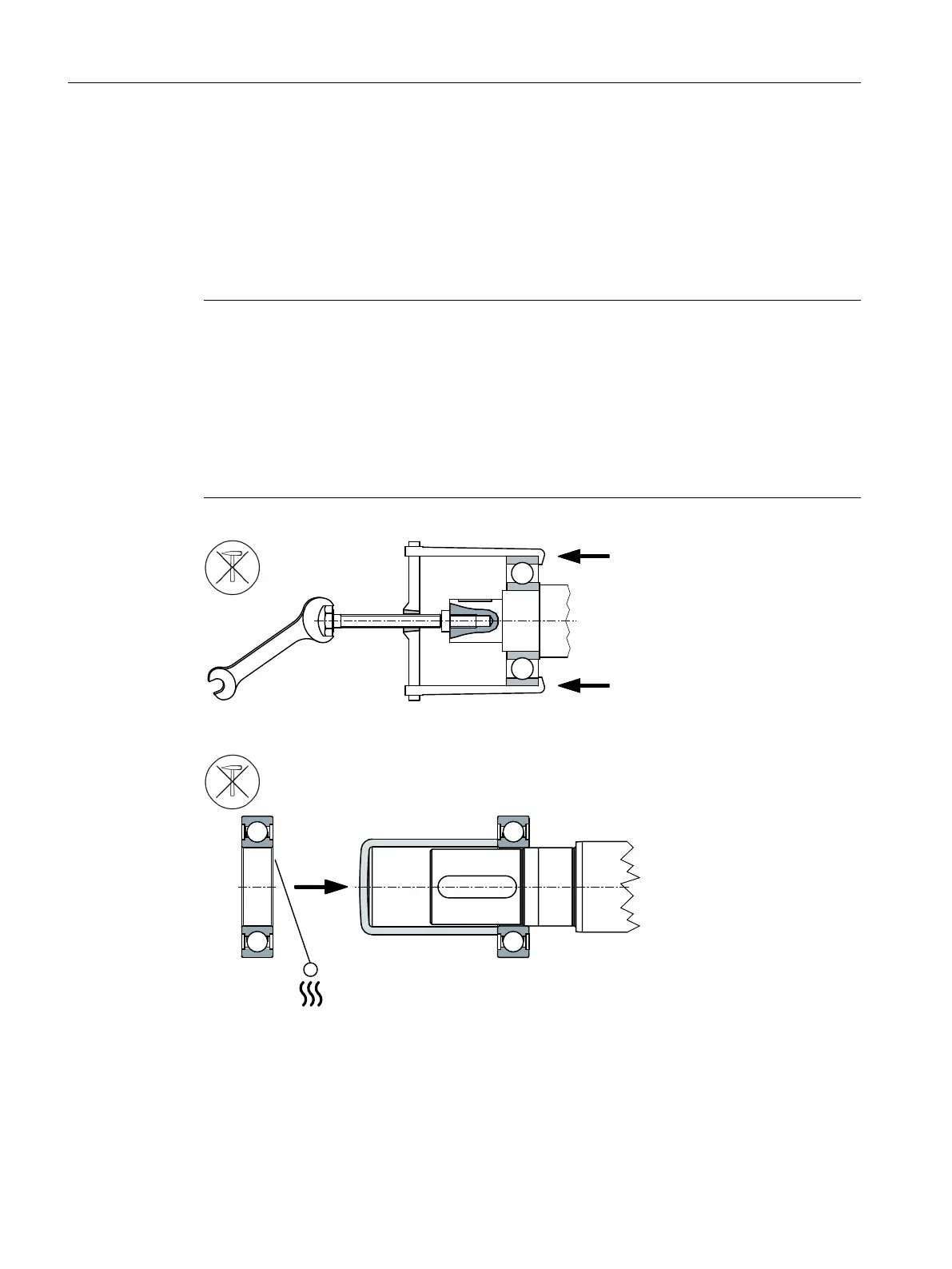

① Heat up 80 ... 100°C

Maintenance

9.3Corrective maintenance

1MB..1/2/3/4 - shaft heights 63 ... 355

130 Operating Instructions, 11/2023, A5E52779900A

Loading...

Loading...