cles in CYCLE mode

5

© Siemens AG, 2002. All rights reserved

SINUMERIK 840D/810D Operator's Guide ManualTurn (BAM) – 08.02 Edition 5-83

Explanation of parameters based on example of tapered

thread

P

Thread pitch

G

Lead change

G = 0 The lead does not change.

G > 0 The lead is increased by the value G.

G < 0 The lead is reduced by the value G.

If the start and end lead of the thread are known, the lead change to

be programmed can be calculated as follows:

|P

e

2

- P

2

|

G = ⎯⎯⎯⎯⎯ [mm/rev

2

]

2*Z

1

Where:

P

e

is the end lead of the thread [mm/rev]

P is the start lead of the thread [mm/rev]

Z

1

is the thread length [mm]

A greater lead means a greater distance between thread turns on the

workpiece.

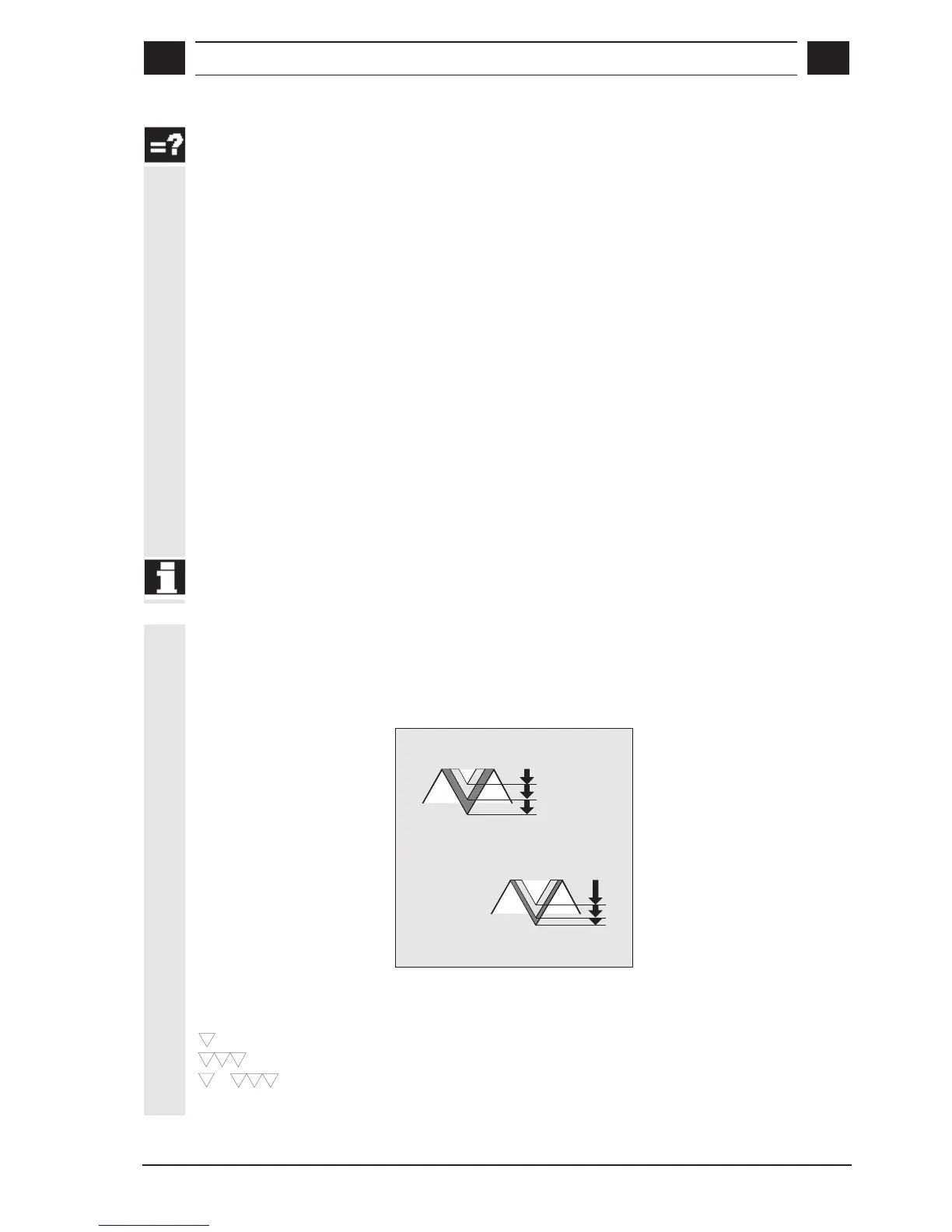

Cut segmentation

(alternative)

LINEAR

DEGRESSIVE

Infeed with constant cutting depth

Infeed with constant cutting cross-section

Infeed with

constant cutting depth

Infeed with

constant cutting cross-section

Machining mode

(alternative)

You can choose between the types of machining:

+

Roughing

Finishing

Complete machining (roughing and finishing)

Loading...

Loading...