cles in STOCK REMOVAL mode

5

© Siemens AG, 2002. All rights reserved

SINUMERIK 840D/810D Operator's Guide ManualTurn (BAM) – 08.02 Edition 5-107

Explanation of parameters

As an example for all grooving cycles, the parameters for the cycle

stored under soft key 8 are explained below. The parameter

description applies equally to the remaining two grooving cycles.

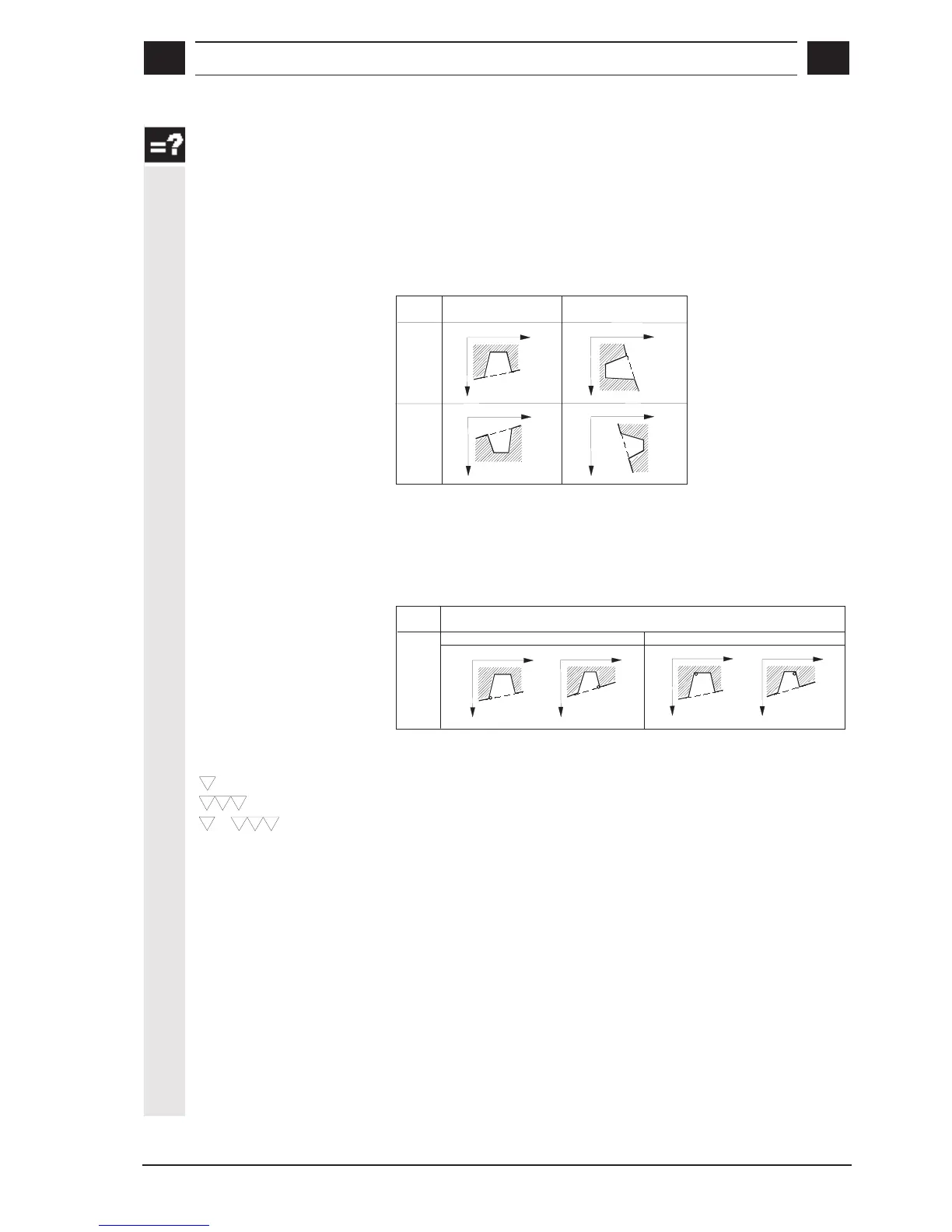

Position

The position of the groove in the coordinate system is defined by

means of this setting.

X

X

Z

Z

X

X

Z

Z

External

Internal

Position

Longitudinal groove

Face groove

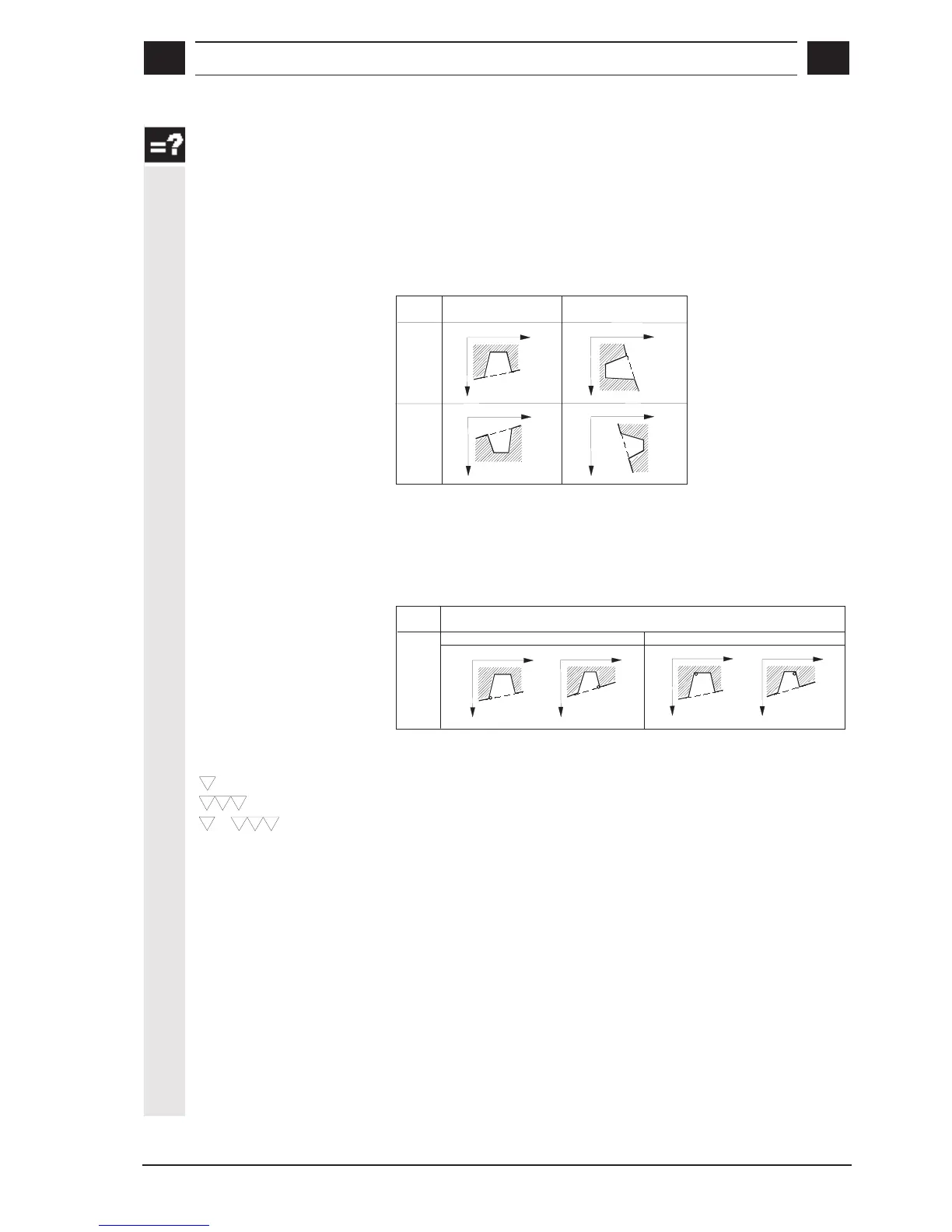

Reference point

You define the reference point on the groove base (reference point

bottom) or the groove edge (reference point top) depending on the

position in the coordinate system.

e.g. for an external longitudinal groove, the following options can be

selected:

X

X

ZZ

External

Position

Longitudinal groove

X

X

ZZ

Reference point top Reference point bottom

Machining mode

Select one of the following machining modes:

+

Roughing

Finishing

Complete machining (roughing and finishing)

X0, Z0

Reference points for dimensioning

These coordinates define the point of a groove from which the cycle

calculates the groove form.

B1, B2

B

1

= Groove width, bottom

B

2

= Groove width, top

T1, T2

T

1

= Settable depth at reference point

T

2

= Depth opposite reference point

Set the groove width B1, B2 and groove depth T1, T2

parameters to

define the groove form. The cycle always bases its calculations on the

point programmed under

X0 and Z0.

Loading...

Loading...