Detailed Description

2.7 Structure and functions of the basic program

PLC Basic Program Solution Line (P3 sl)

2-58 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

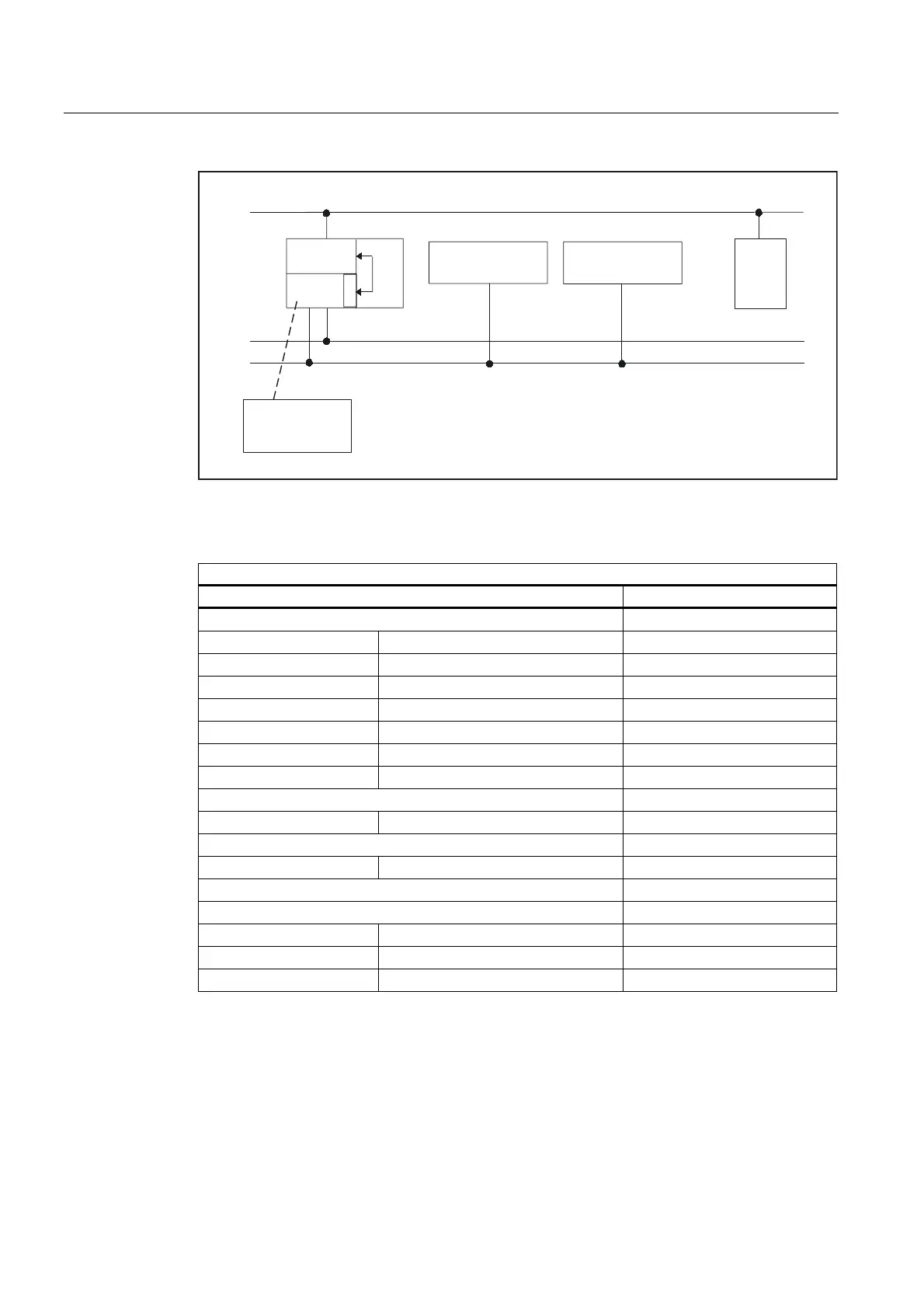

03,'3

'3

++8

1&.

(WKHUQHW

0&3

0&3

'

3

5

3URILEXVFRQI

IRU0&3++8

&3

'VO

LQW3/&

Fig. 2-17 PROFIBUS connection

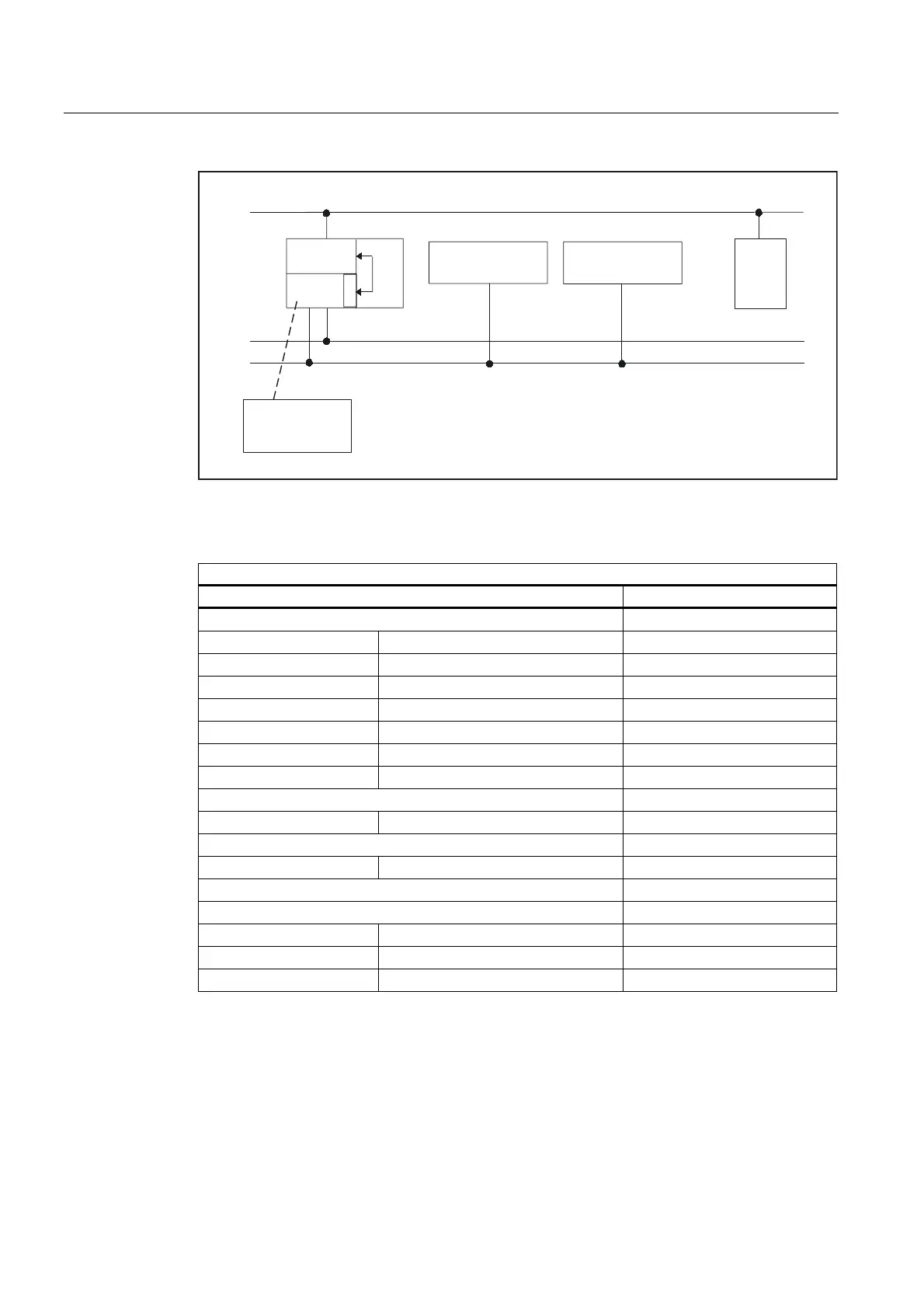

Relevant parameters (FB1)

MCP HHU

MCPNum = 1 or 2 (number of MCPs) HHU = 5 (via CP 840D sl)

MCP1In MCP2In BHGIn

MCP1Out MCP2Out BHGOut

MCP1StatSend (n.r.) MCP2StatSend (n.r.) BHGStatSend

MCP1StatRec MCP2StatRec BHGStatRec

MCP1BusAdr MCP2BusAdr BHGInLen

MCP1Timeout MCP2Timeout BHGOutLen

MCP1Cycl (n.r.) MCP2Cycl BHGTimeout

MCPMPI = FALSE BHGCycl

MCP1Stop MCP2Stop BHGRecGDNo

MCPBusType = b#16#33 BHGRecGBZNo (n.r.)

BHGRecObjNo (n.r.)

MCPSDB210= FALSE BHGSendGDNo (n.r.)

MCPCopyDB77 = FALSE BHGSendGBZNo (n.r.)

BHGSendObjNo (n.r.)

BHGMPI = FALSE

BHGStop

MCP failure switches the PLC to the STOP state. If this is undesirable, OB 82, OB 86 can be

used to avoid a stop. Setting MCPxStop := True deactivates the MCP as a slave via SFC 12.

If the PLC does not switch to the stop state following the failure of or a fault on the MCP, an

interrupt message will be generated via the basic program. The interrupt is deleted when the

station recovers.

Loading...

Loading...