Detailed Description

2.5 Referencing with distance-coded reference marks

Reference Point Approach (R1)

2-22 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

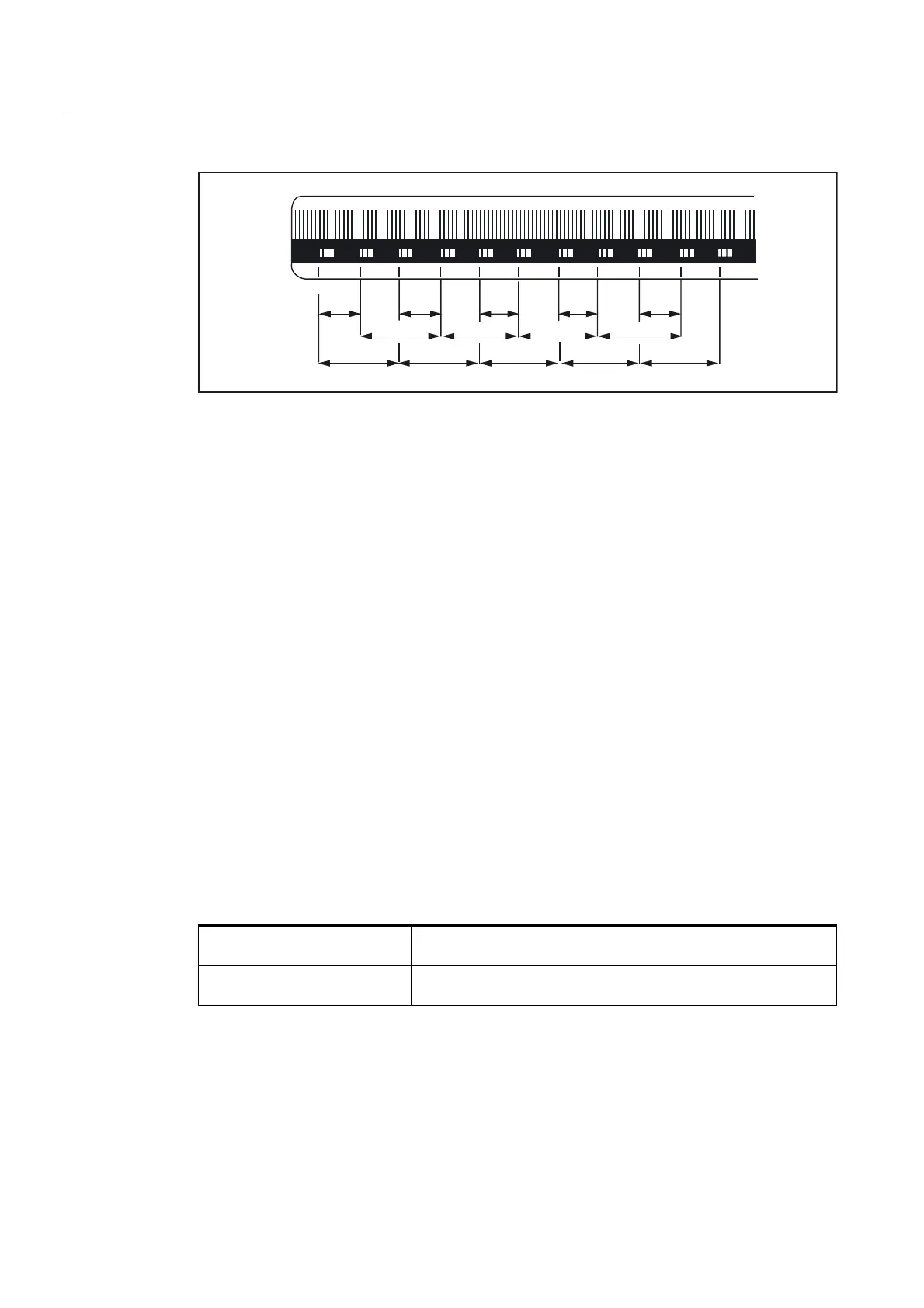

5HIHUHQFHPDUN

Fig. 2-11 DIADUR graduated glass scale with distance-coded reference marks

(dimensions in mm for 20 mm scale division)

Rotary measuring system

For rotary measuring systems, the same applies as for linear measuring systems (see

above).

Determining the absolute offset

In order to determine the absolute offset between machine zero and the position of the 1st

reference mark of a machine axis, the following procedure is recommended:

1. The value zero must be entered for the absolute offset:

MD34090 $MA_REFP_MOVE_DIST_CORR = 0

2. Perform reference point approach.

Note: Reference point approach should be performed at a point in the machine where the

exact position of the machine axis relative to machine zero can be determined easily with

a laser interferometer, for example.

3. Determine the actual position of the machine axis via the HMI user interface.

4. Measure the current position of the machine axis with reference to machine zero.

5. Calculation of absolute offset.

The absolute offset is calculated with respect to the machine coordinate system and

depending on the orientation of the measuring system (equidirectional or inverse) as:

Equidirectional orientation: Absolute offset =

Measured position + indicated actual position

Inverse orientation: Absolute offset =

Measured position - indicated actual position

Loading...

Loading...