Detailed Description

2.4 Tool: Tool radius compensation 2D (TRC)

Tool Compensation (W1)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-49

• Modal G code (G340, G341), which defines the subdivision of the movement into

individual blocks from the start point to the end point

6WUDLJKWOLQH

RUFLUFOH

,QIHHGPRYHPHQW

6WUDLJKWOLQH

FLUFOHRUKHOL[

0DFKLQLQJSODQH

*

*

3 33 3

',6&/ ',6&/

33 3

3 33

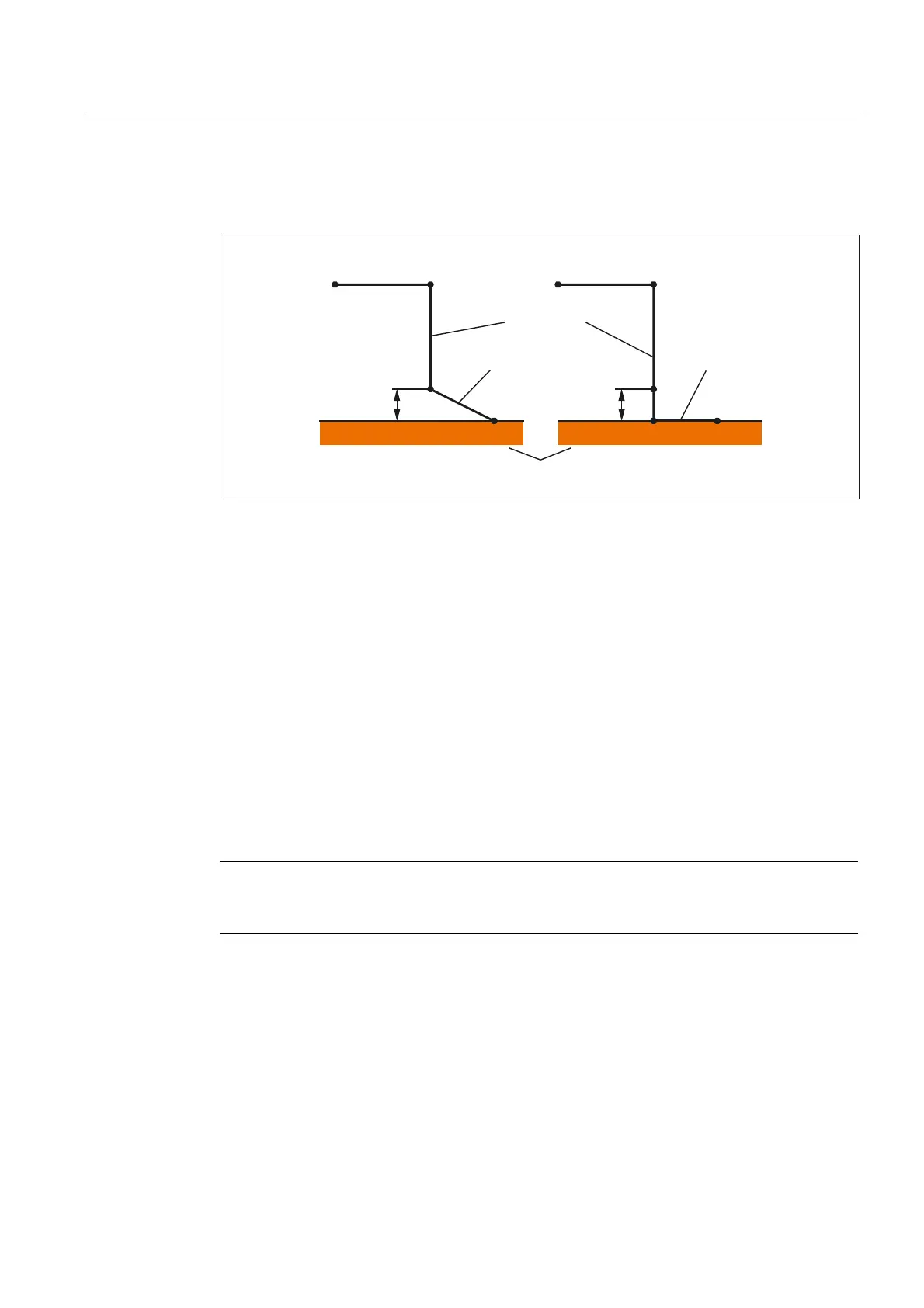

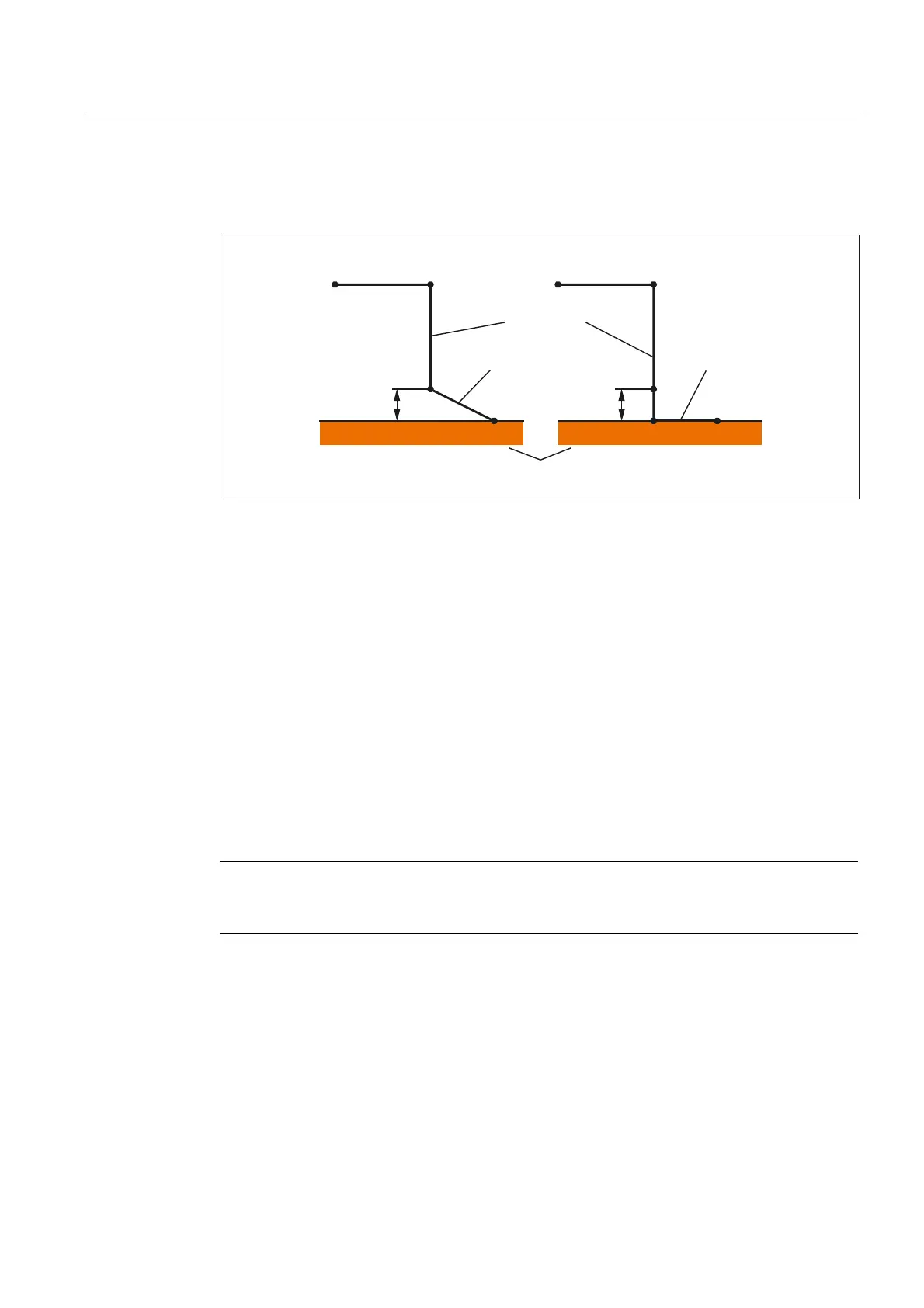

Fig. 2-20 Sequence of the approach movement depending on G340/G341

G340: The approach characteristic from P

0

to P

4

is shown in the figure.

If G247 or G347 is active (quadrant or semicircle) and start point P

3

is outside the machining

plane defined by the end point P

4

, a helix is inserted instead of a circle. Point P

2

is not

defined or coincides with P

3

.

The circle plane or the helix axis is determined by the plane, which is active in the SAR

block (G17 - G19), i.e., the projection of the start tangent is used by the following block,

instead of the tangent itself, to define the circle.

The movement from point P

0

to point P

3

takes place along two straight lines at the velocity

valid before the SAR block.

G341: The approach characteristic from P

0

to P

4

is shown in the figure.

P

3

and P

4

are located within the machining plane, with the result that a circle is always

inserted instead of a helix with G247 or G347.

Note

Active, rotating frames are included in all cases where the position of the active plane G17 -

G19 (circle plane, helix axis, infeed movements perpendicular to the active plane) is relevant.

Loading...

Loading...