Detailed Description

2.8 Special handling of tool compensations

Tool Compensation (W1)

2-126 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

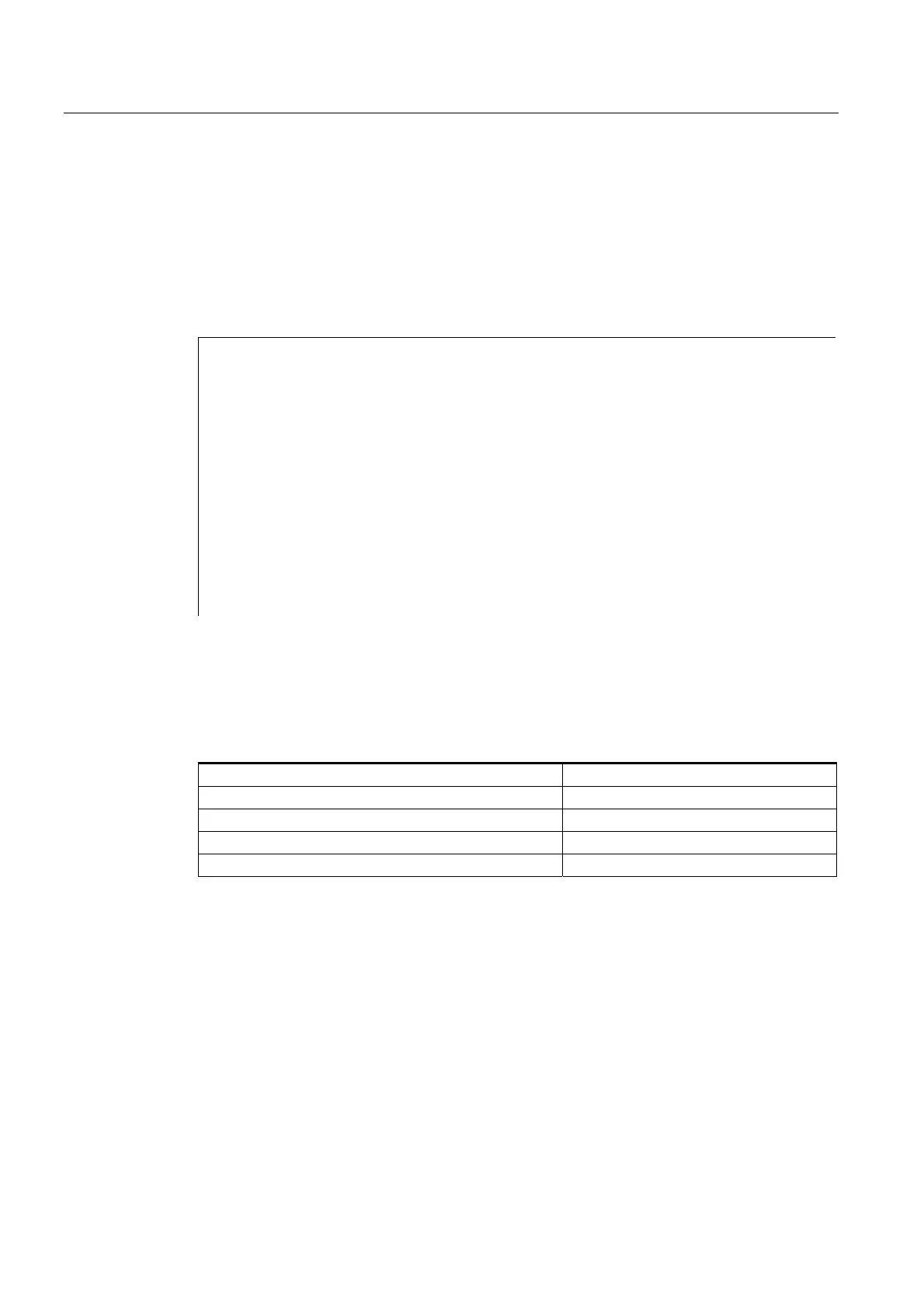

NC program

Temperature compensation values in the NC program

The compensation values assigned to axes X and Z are not zero and are applied for

temperature compensation with respect to tool length. The machine axis positions reached in

each case are specified as comments in the program lines.

SD42960 TOOL_TEMP_COMP[0] = -0.3 ; First compensation value

SD42960 TOOL_TEMP_COMP[1] = 0.0 ;

SD42960 TOOL_TEMP_COMP[2] = -1.0 ; Second compensation value

; Position setpoints of the

machine axes

N10 g74 x0 y0 z0 a0 b0 ; X Y Z

N20 x20 y20 z20 f10000 ; 20.30 20.00 21.00

N30 traori() ; 20.30 20.00 21.00

N40 x10 y10 z10 b90 ; 11.00 10.00 9.70

N50 trafoof ; 10.30 10.00 11.00

N60 x0 y0 z0 b0 c0 ; 0.30 0.00 1.00

N70 m30

With the exception of block N40, temperature compensation always acts in the original

directions, as the tool is pointing in the basic orientation direction. This applies particularly in

block N50. The tool is actually still pointing in the direction of the X axis because the B axis is

still at 90 degrees. However, because the transformation is already deactivated, the applied

orientation is parallel to the Z axis again.

MD20390 TOOL_TEMP_COMP_ON = TRUE ; Temperature compensation active

Option ; Activate option

MD32750 TEMP_COMP_TYPE[ AX1 ] = 4 ; Compensation in tool direction

MD32750 TEMP_COMP_TYPE[ AX2 ] = 4 ; Compensation in tool direction

MD32750 TEMP_COMP_TYPE[ AX3 ] = 4 ; Compensation in tool direction

For more information about temperature compensation, please refer to:

References:

/FB2/ Description of Functions, Extended Functions; Compensations (K3).

For more information about generic 5-axis transformation, please refer to:

References:

/FB3/ Description of Functions, Special Functions; 3- to 5-axis Transformation (F2)

Loading...

Loading...