Detailed Description

2.3 Axis/spindle service display

Diagnostic Tools (D1)

2-12 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

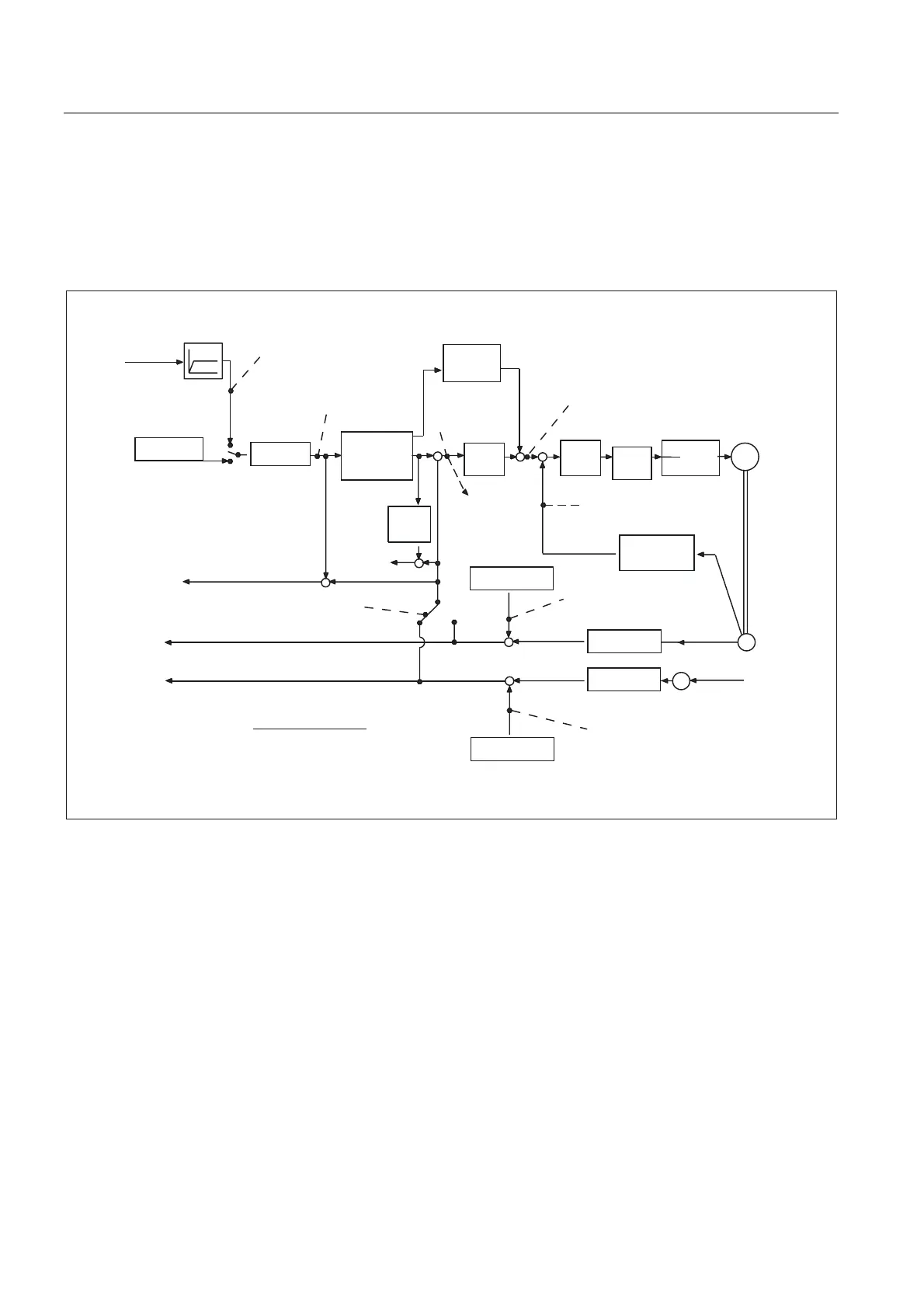

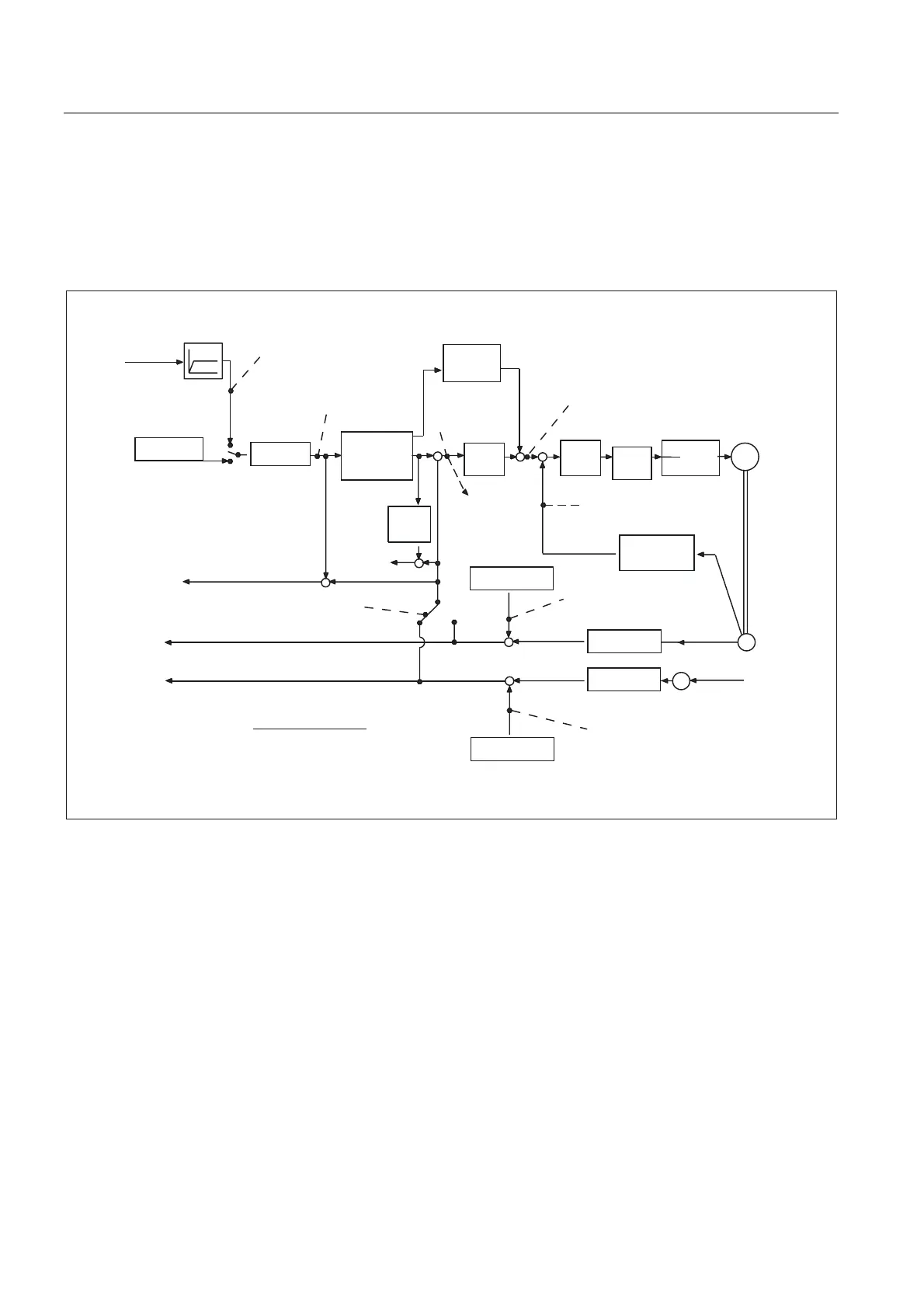

Control technology concept

The figure below shows at which points in the controlloop the axis and spindle information is

read off.

0

3RVLWLRQ

FRQWURO

OHU

Spindle speed setpoint

current

Error signal

Position setpoint

(speed setpoint)

Spindle

speed

setpoint

prog.

Abs. compensation value

Measuring system 2

Speed setpoint [%]

*

*

Actual speed value [%]

Control

parameter set

Contour

deviation

Following error

e.g. from

direct

measuring

system

Abs. compensation value

Measuring system 1

Actual position value of measuring system 2

Actual position value of measuring system 1

Active

measuring

system

6HUYRJDLQIDFWRUFDOFXODWHG

6SHHGVHWSRLQW

)ROORZLQJHUURU

9DOXHLVGLVSOD\HGLQXVHULQWHUIDFH

,WDOLFIRQW

)LQH

LQWHUSRODWRU

-HUNOLPLWDWLRQ

'\QDPLF

UHVSRQVH

DGDSWDWLRQ

)HHG

IRUZDUG

FRQWURO

&RQWURO

ORRS

PRGHO

6SHHG

FRQW

UROOHU

&XUUHQW

FRQWURO

OHU

3RZHU

VHFWLRQ

$FWXDOVSHHG

YDOXH

VSHFLILFDWLRQ

&RPSHQVDWLRQ

%DFNODVK/(&

$FWXDOYDOXH

SURFHVVLQJ

$FWXDOYDOXH

SURFHVVLQJ

&RPSHQVDWLRQ

%DFNODVK/(&

,QWHUSRODWRU

,32

식

Fig. 2-2 Overview diagram of axis and spindle information

Checks

Check of the position controller setting

A simple check of the position controller setting can be made by means of the service axis

screen.

To this end, the number 1 (corresponding to KV = 1) is entered in machine datum:

MD32200 $MA_POSCTRL_GAIN [n] (KV factor).

The change takes effect immediately.

Loading...

Loading...