Detailed Description

2.1 General functionality

Travel to Fixed Stop (F1)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-3

Functional sequence

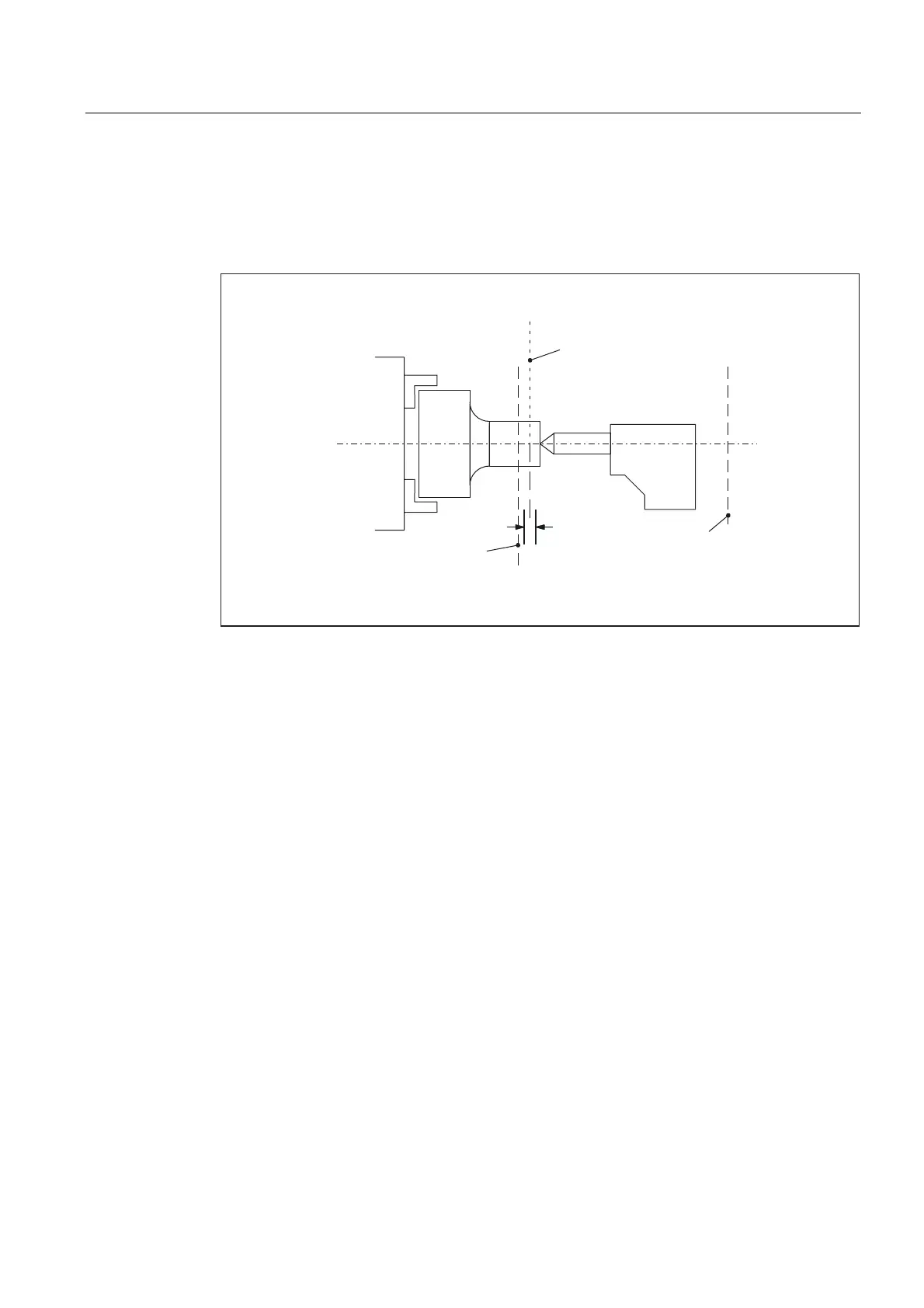

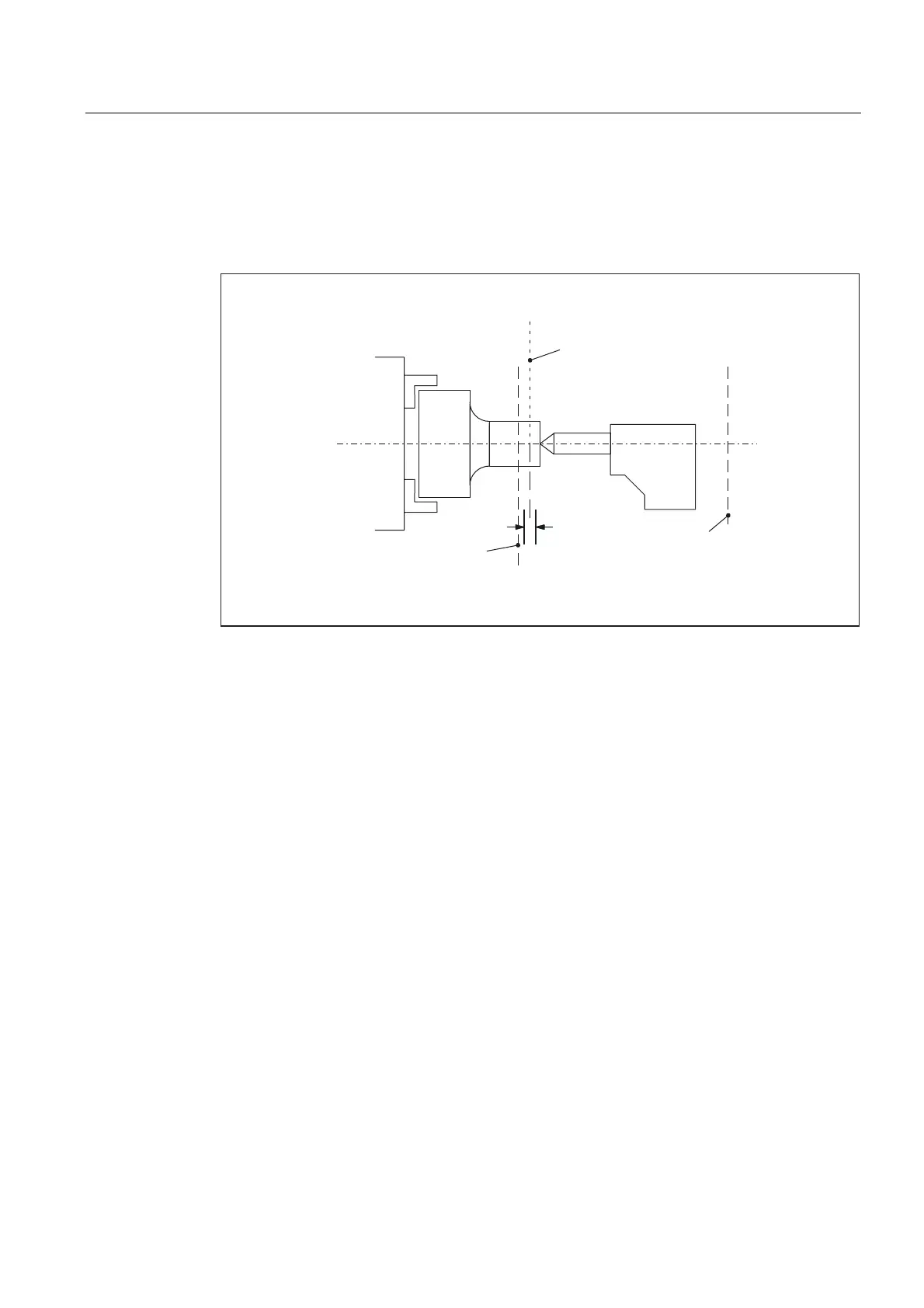

The function is explained by the example below (sleeve is pressed onto workpiece).

$FWXDOSRVLWLRQDIWHUWUDYHO

WRIL[HGVWRS

3URJUHQG

SRVLWLRQ

6WDUWSRVLWLRQ

)L[HGVWRS

PRQLWRULQJZLQGRZ

Fig. 2-1 Example of travel to fixed stop

Selection

The NC detects that the function "travel to fixed stop" is selected via the command

FXS[x]=1 and signals the PLC via the IS "Activate travel to fixed stop" (DB31, ... DBX62.4)

that the function has been selected.

When the machine parameter:

MD37060 FIXED_STOP_ACKN_MASK

(register PLC acknowledgments for travel to fixed stop)

is set accordingly, the IS waits for acknowledgment by the PLC via IS "Activate travel to fixed

stop" (DB31, ... DBX3.1).

The programmed target position is then approached from the start position at the

programmed velocity. The fixed stop must be located between the start and target positions

of the axis/spindle. A programmed torque limit is effective from the start of the block, i.e. the

fixed stop is also approached with reduced torque. Allowance for this limitation is made in

the NC through an automatic reduction in the acceleration rate.

If no torque was programmed in the block or since the beginning of program, the value

entered in the axis specific machine parameter:

MD37010 FIXED_STOP_TORQUE_DEF

(default setting for clamping torque)

applies.

Loading...

Loading...