Detailed Description

2.2 Metric/inch measuring system

Velocities, Setpoint/Actual-Value Systems, Closed-Loop Control (G2)

Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

2-15

Example 2:

The definition is made here by programming G71 in the synchronized action.

N100 R1=0

N110 G0 X0 Z0

N120 WAITP(X)

N130 ID=1 WHENEVER $R1==1 DO G71 POS[X]=10

N140 R1=1

N150 G71 Z10 F10 ;Z=10 mm X=10 mm

N160 G70 Z10 F10 ;Z=254 mm X=10 mm (X posit. always at 0 mm)

N170 G71 Z10 F10 ;Z=10 mm X=10 mm

N180 M30

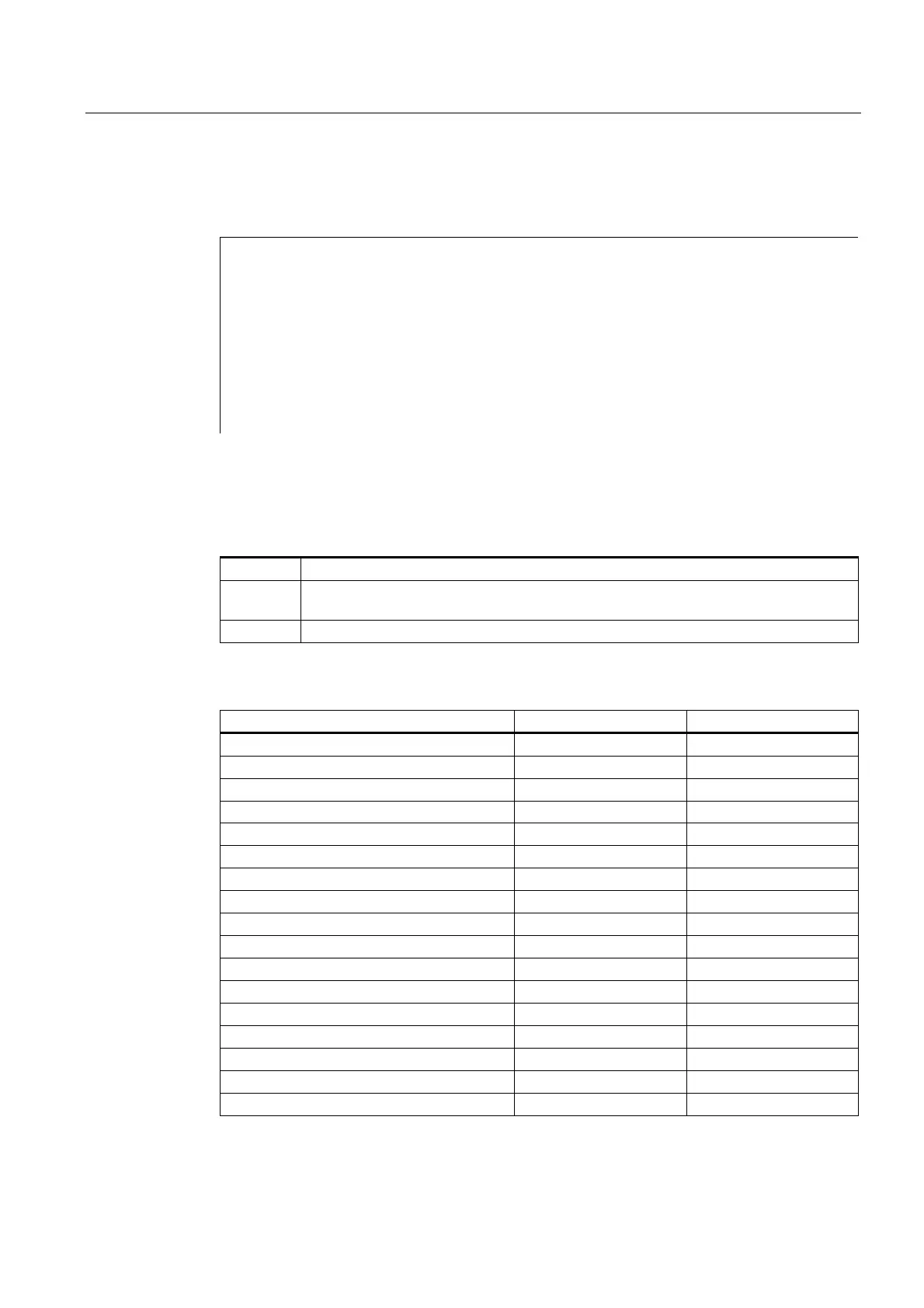

Comparison: G70/G71-G700/G710

Where:

P: Data is read/written in the programmed measuring system

G: Data is read/written in the basic system

(MD10240 $MN_SCALING_SYSTEM_IS_METRIC).

R/W: Read/Write

Comparison:

Range G70/G71 G700/G710

Parts program Parts program

R/W R/W

Display, decimal places (WCS) P/P P/P

Display, decimal places (MCS) G/G G/G

Feedrates G/G P/P

Positional data X, Y, Z P/P P/P

Interpolation parameters I, J, K P/P P/P

Circle radius (CR) P/P P/P

Polar radius (RP) P/P P/P

Pitch P/P P/P

Programmable FRAME P/P P/P

Settable FRAMES G/G P/P

Basic frames G/G P/P

Work offsets external G/G P/P

Axial preset offset G/G P/P

Operating range limit (G25/G26) G/G P/P

Protection zones P/P P/P

Loading...

Loading...