Detailed Description

2.10 System settings for power-up, RESET/part-program end and part-program start

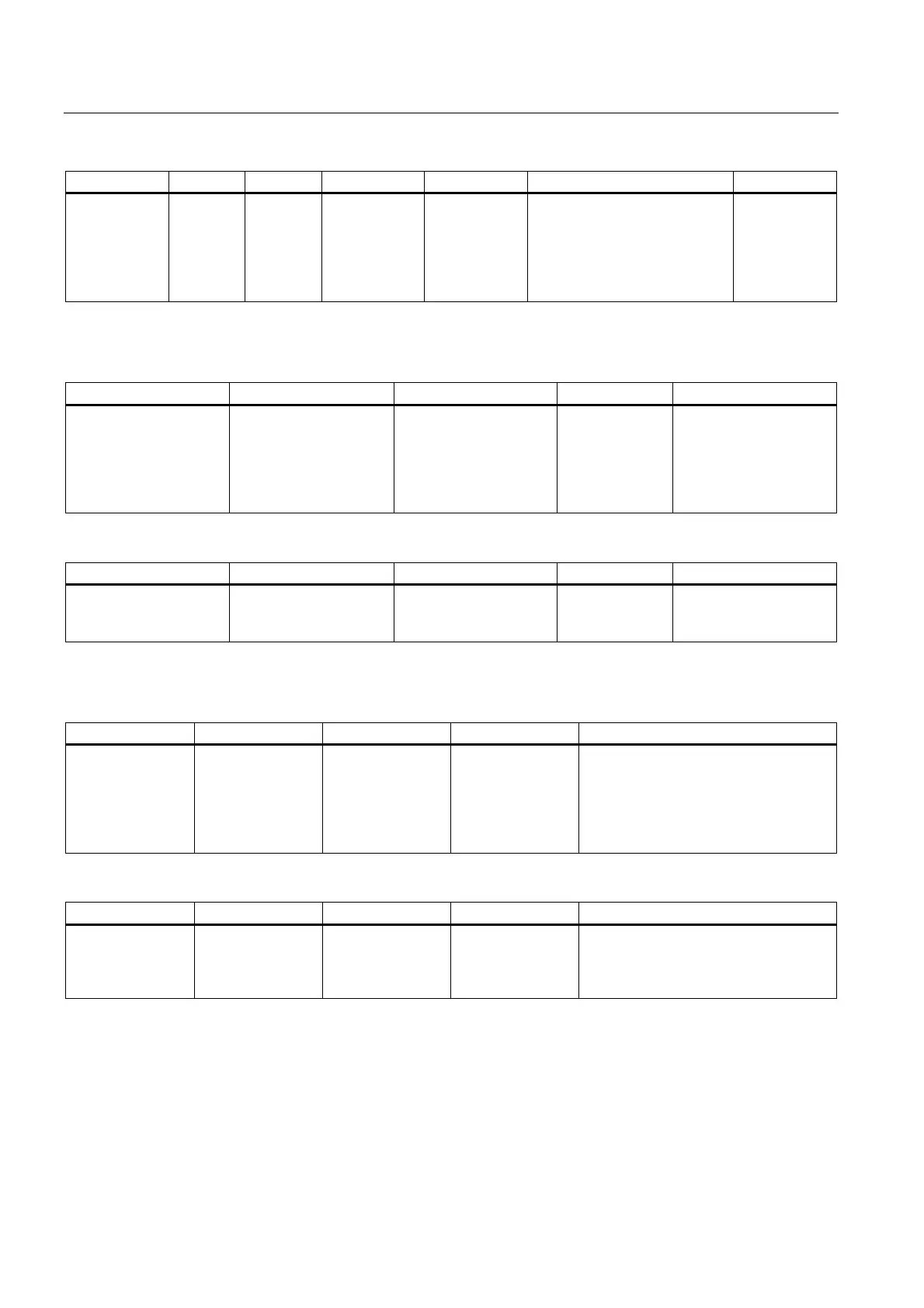

Mode Group, Channel, Program Operation, Reset Response (K1)

2-142 Function Manual, 08/2005 Edition, 6FC5397-0BP10-0BA0

Bit 1 = 0 Bit 2 = 0 Bit 3 = 0 Bit 4 = 0 Bit 5 = 0 Bit 6 = 0 Bit 7 = 0

D, T, M output

on tool

selection;

with active tool

management

irrelevant

Reserved Reserved Current plane

is retained

Current

settable frame

is retained

Active tool length offset is

retained

Active

transformation

is retained

Table 2-17 Effect of MD20112 $MC_START_MODE_MASK Bits 8 to 12

Bit 8 = 1 Bit 9 = 1 Bit 10 = 1 Bit 11 = 1 Bit 12 = 1

Coupledaxis groupings

are deactivated

Tangential follow-up is

deactivated

Not configured

synchronous spindle

coupling is switched off

Reserved Geometry axis

assignment is deleted

according to MD 20050,

depending on MD

20118 (because of

compatibility)

Bit 8 = 0 Bit 9 = 0 Bit 10 = 0 Bit 11 = 0 Bit 12 = 0

Coupledaxis groupings

are retained

Tangential follow-up is

retained

Not configured

synchronous spindle

coupling remains active

Reserved Modified geometry axis

assignment is retained

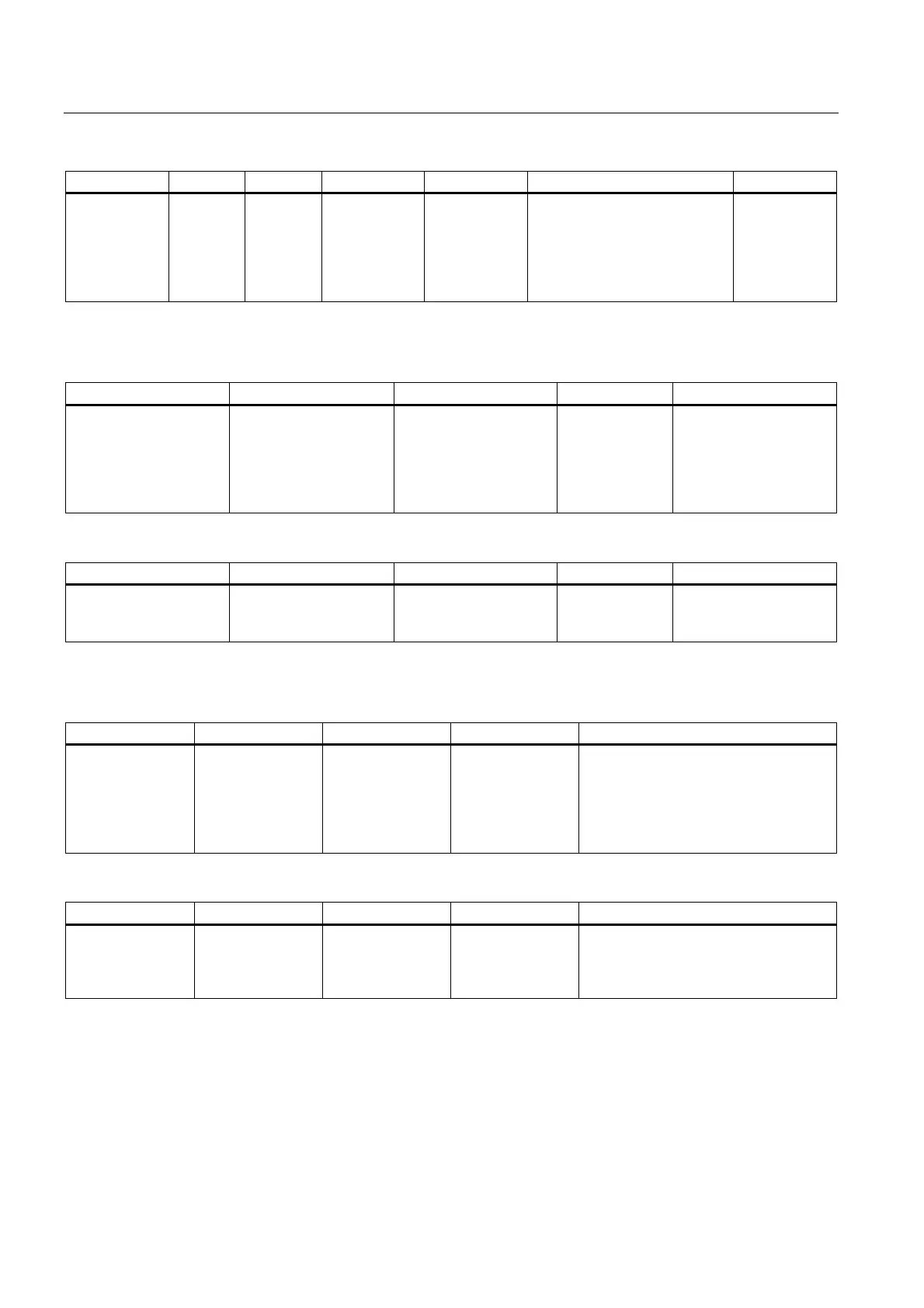

Table 2-18 Effect of MD20112 $MC_START_MODE_MASK Bits 13 to 17

Bit 13 = 1 Bit 14 = 1 Bit 15 = 1 Bit 16 = 1 Bit 17 = 1

Guide value

coupling is

separated

Reserved for

basic frame

Reserved for

electronic gears

Initial setting for

master spindle

according to

MD20090

$MC_SPIND_DEF

_MASTER_SPIND

Only if MD20124

$MC_TOOL_MANAGEMENT_

TOOLHOLDER > 0: Initial setting for

the master tool holder according to

MD 20124 $MC_Otherwise setting for

master spindle

Bit 13 = 0 Bit 14 = 0 Bit 15 = 0 Bit 16 = 0 Bit 17 = 0

Active guide value

coupling is

retained

Reserved for

basic frame

Reserved for

electronic gears

Current setting of

the master spindle

(SETMS) is

retained

The current setting of the

master tool holder (SETMS) is retained

Loading...

Loading...