Commissioning

7.3 Commissioning via Quick Start routine

SIWAREX WT241

56 Manual, 05/2015, A5E36046748A

Additional parameter settings can also be made, for example:

● Setting of limits for belt load, speed, and material flow rate

● Filter settings

● Parameterization of the inputs/outputs of your weighing module

Further information on these and all other parameters can be found in chapter → Scale

parameters and functions of the belt scale (Page 59).

You can return to the main screen using the "Home" button (house symbol).

You can improve the results for your system even further following completion of the

calibration or also during subsequent operation by means of a flow correction by material

test ( → Determination of a correction factor (Page 57)).

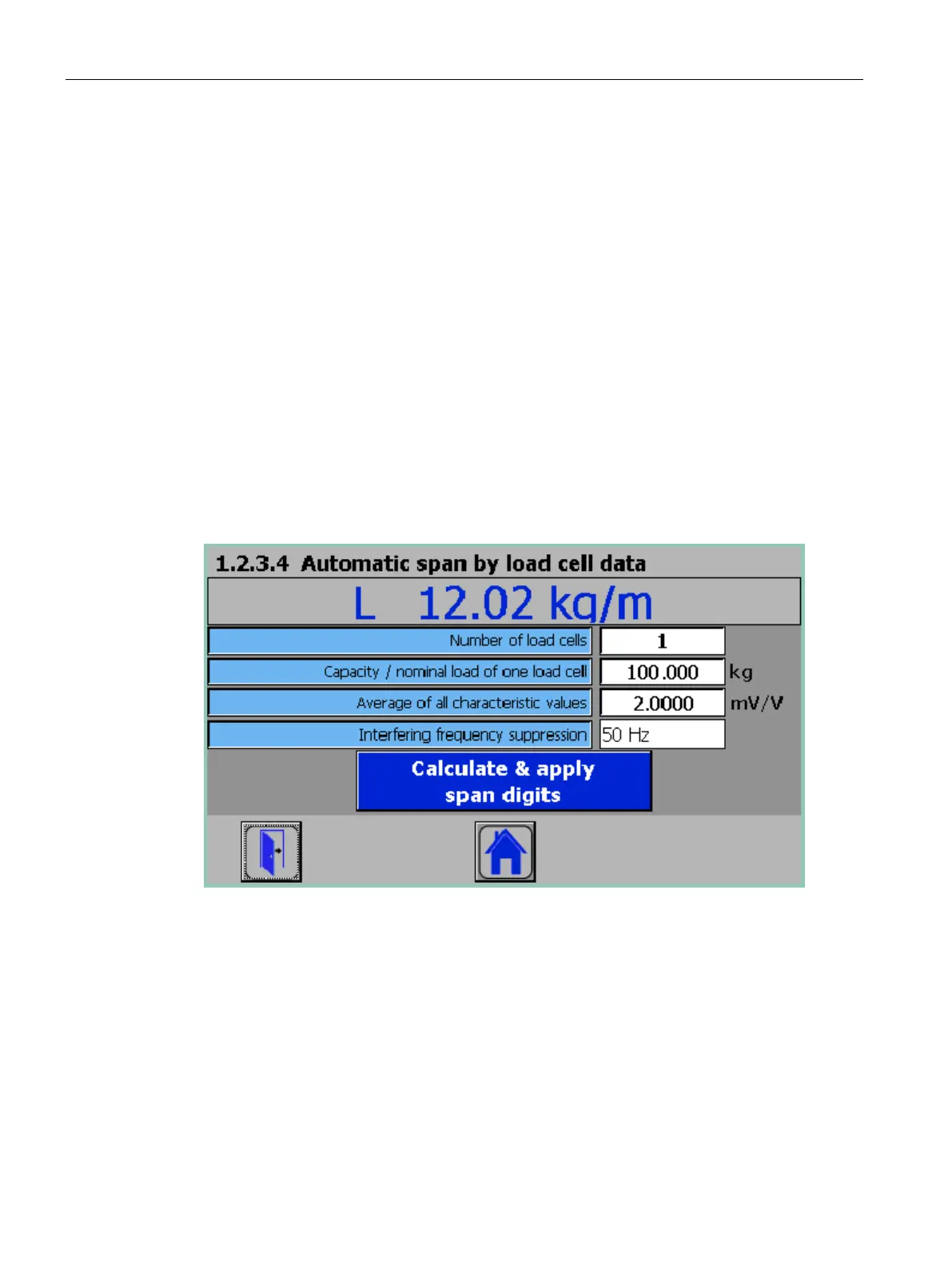

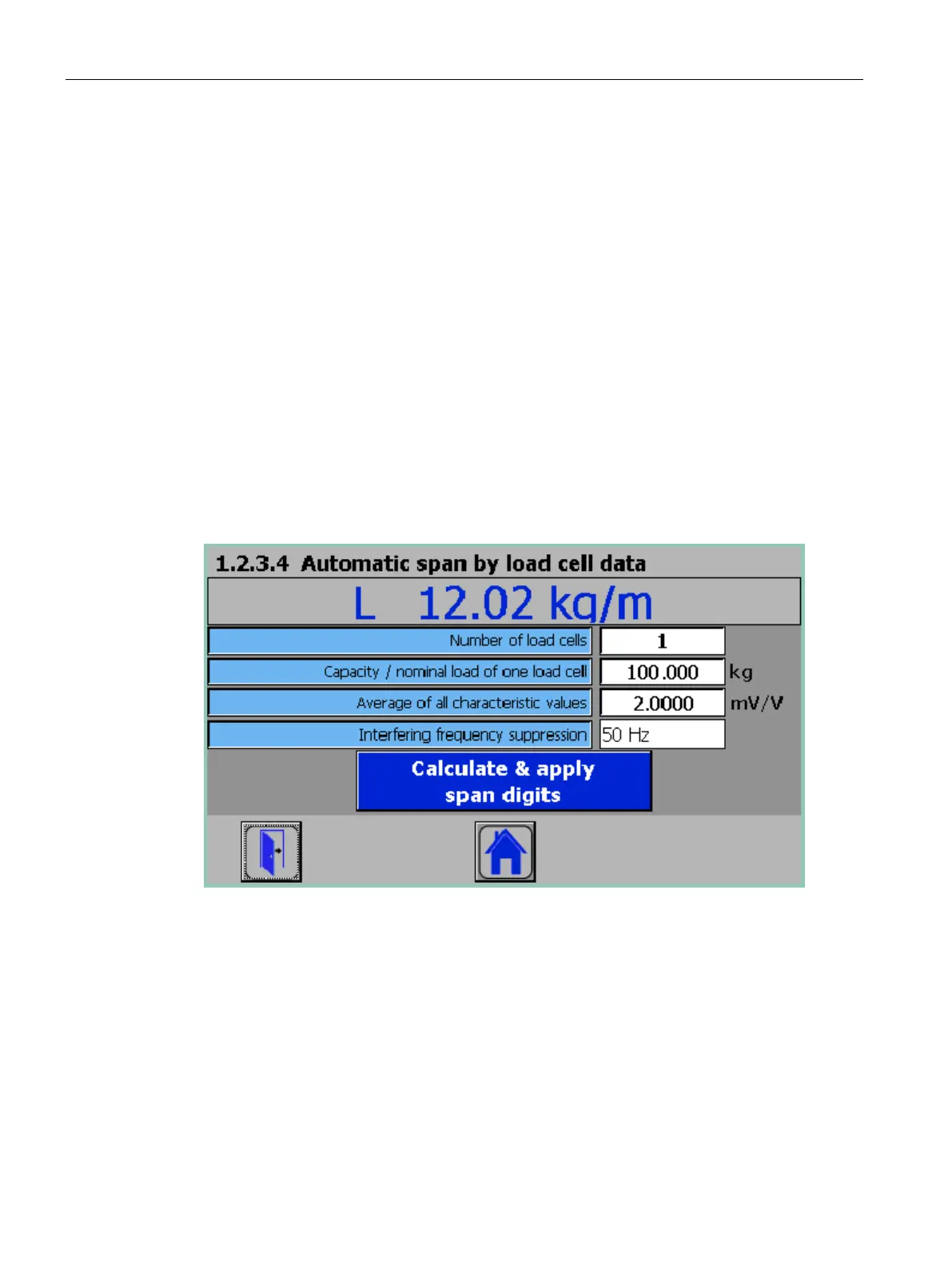

7.3.2.10 Automatic span calibration

By entering the technical specifications of the used load cells, you can automatically carry

out the span calibration without using weights or material.

Navigate in the span calibration menu to item "1.2.3.4 Automatic span by load cell data".

Figure 7-14 Automatic span calibration

A prerequisite for this step is a successful zero calibration.

1. Enter the number of used load cells and the nominal load of one cell.

2. Enter the average of all load cell characteristic values: If the exact characteristic values of

the cells are unknown, you can enter coarse values such as 1.0 mV/V, 2.0 mV, 3.0 mV/V

or 4.0 mV/V.

3. Select the interfering frequency suppression. The interfering frequency suppression is

used to effectively filter out interferences from the power supply network (50 Hz/60 Hz).

Loading...

Loading...