Command lists

10.2 Command lists

SIWAREX WT241

88 Manual, 05/2015, A5E36046748A

10.2 Command lists

The commands for the electronic weighing system described here can be transmitted by

several interfaces:

● by the Operator Panel directly to the SIWAREX module

● by a PLC system e.g. via Modbus RTU

A data or command error is signaled if a command cannot be executed or if the sent data

record is rejected.

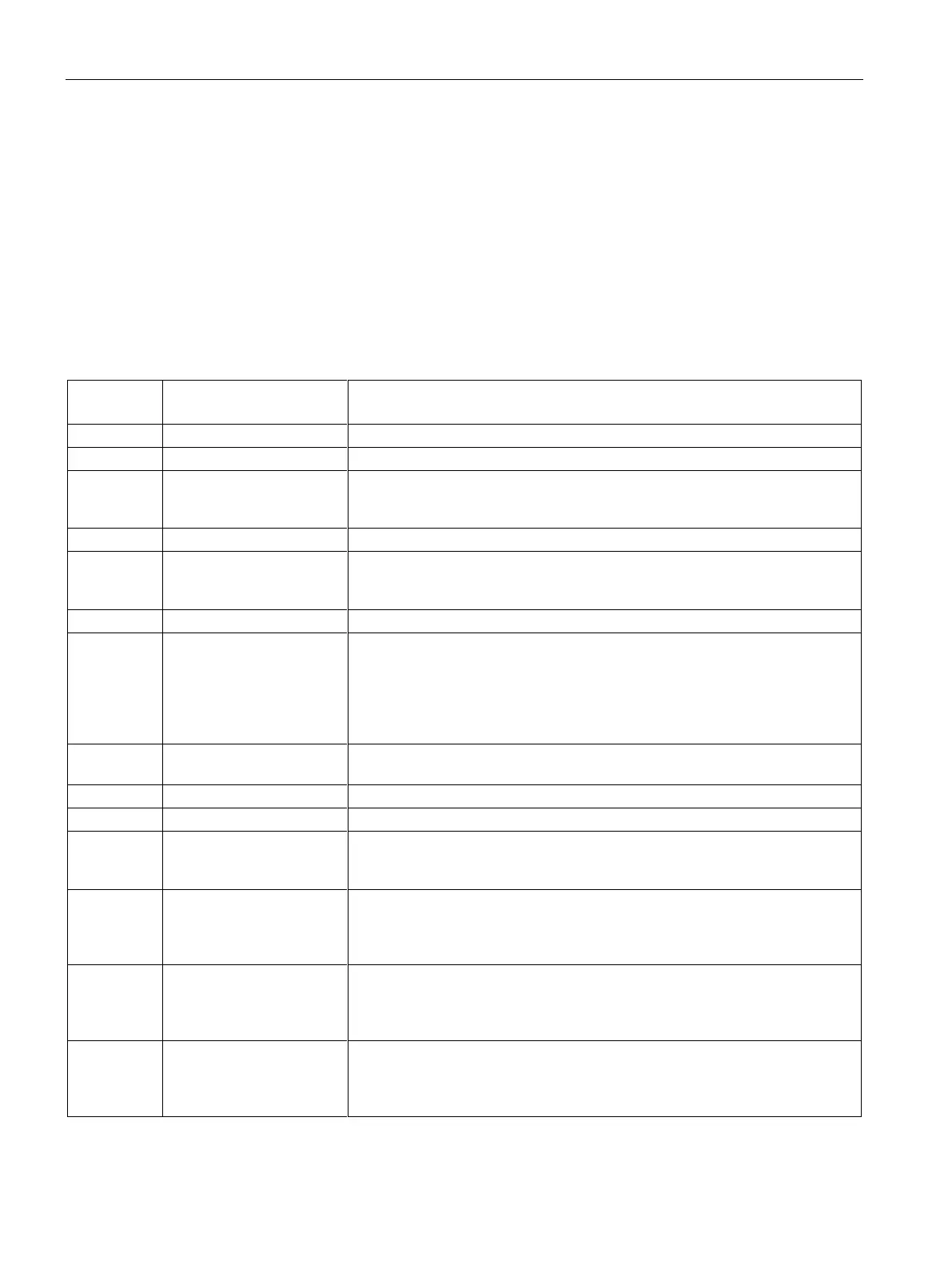

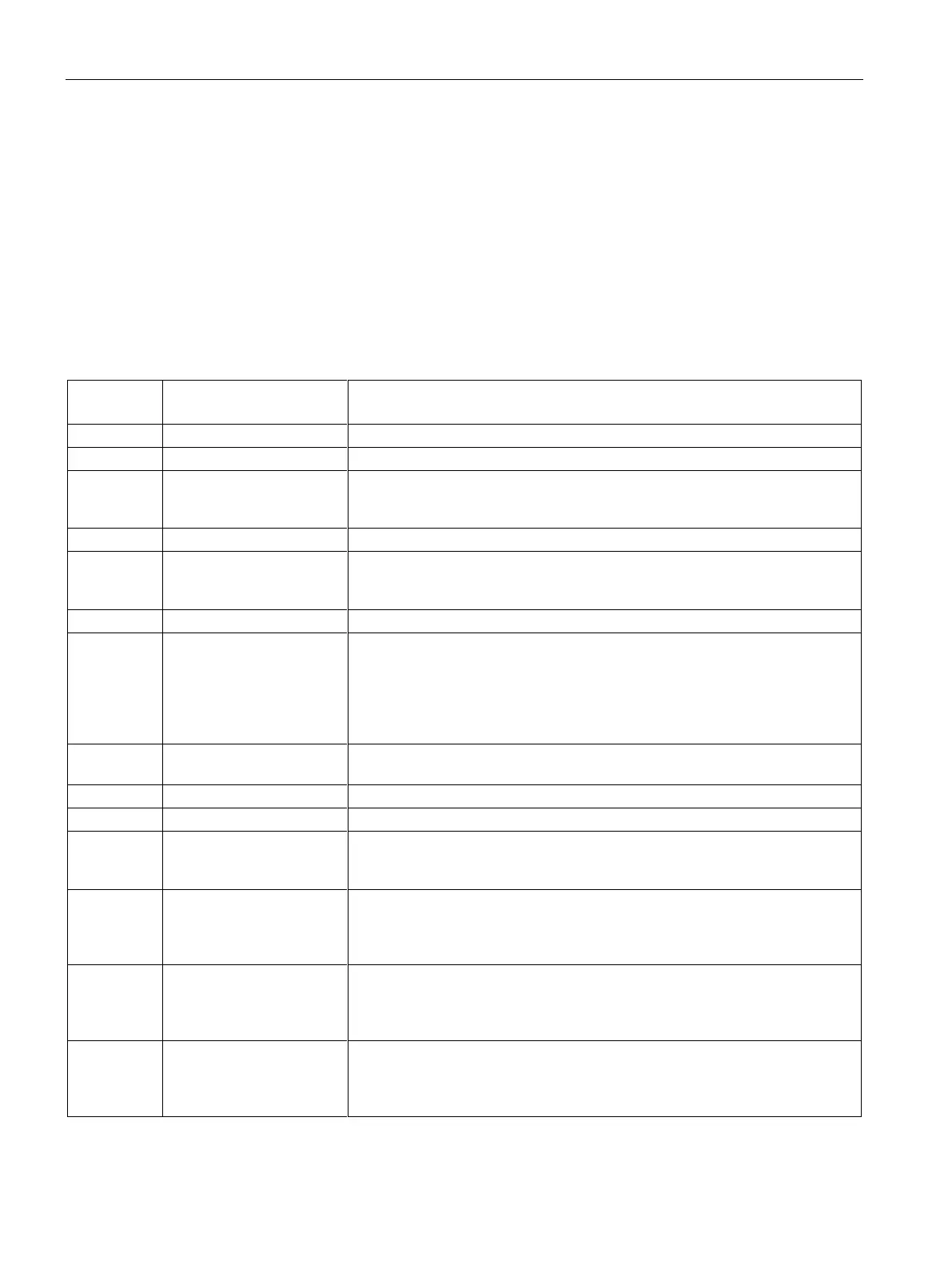

Table 10- 1 Commands 1 ... 99: Service commands

Turn on test mode. The simulation value from data record 16 is used instead

of the measured value as the belt load value. The simulation must first be

released in DR3.

Switch off test mode for belt load.

Turn on test mode. The simulation value from data record 16 is used instead

of the measured value as the belt speed. The simulation must first be released

in DR3.

Switch off test mode for speed.

The command resets the SIWAREX to the "ex works" status. During this pro-

cess:

- All parameters and saved data (including protocol memory, all totalizers (in-

cluding master totalizer), and logbook) as well as the restore point are loaded

with the default values

- All message buffers (diagnostics buffer, trace memory, etc.) are reset

Like "Load factory settings" (command code 11), but interface settings for

Ethernet and Modbus RTU are not reset to the factory setting.

All parameters saved in the restore point are activated.

Saves the parameters of the restore point to the memory.

Start initial zero calibration

Start initial zero calibration. The zero point of the scale characteristic is deter-

mined for the parameterized number of belt revolutions. The result is initially

entered in DR4 and can then be imported into DR3 using command 88.

Start span calibration with

test weight

Start of span calibration with a test weight. The weight value is specified in

data record 3. The span of the scale characteristic is determined for the pa-

rameterized number of belt revolutions. The result is initially entered in DR4

and can then be imported into DR3 using command 89.

Start automatic span cali-

bration

Following a successful zero calibration, command 63 and the load cell data

from DR10 can be used to calculate the span. If the belt has not been installed

horizontally, the angle must be subsequently entered in DR15. The result is

directly imported into DR3 and DR4 and is therefore immediately active.

Start span calibration by

test chain

Start of span calibration with a test chain. The load value is specified in data

record 3. The span of the scale characteristic is determined for the parameter-

ized number of belt revolutions. The result is initially entered in DR4 and can

then be imported into DR3 using command 89.

Loading...

Loading...