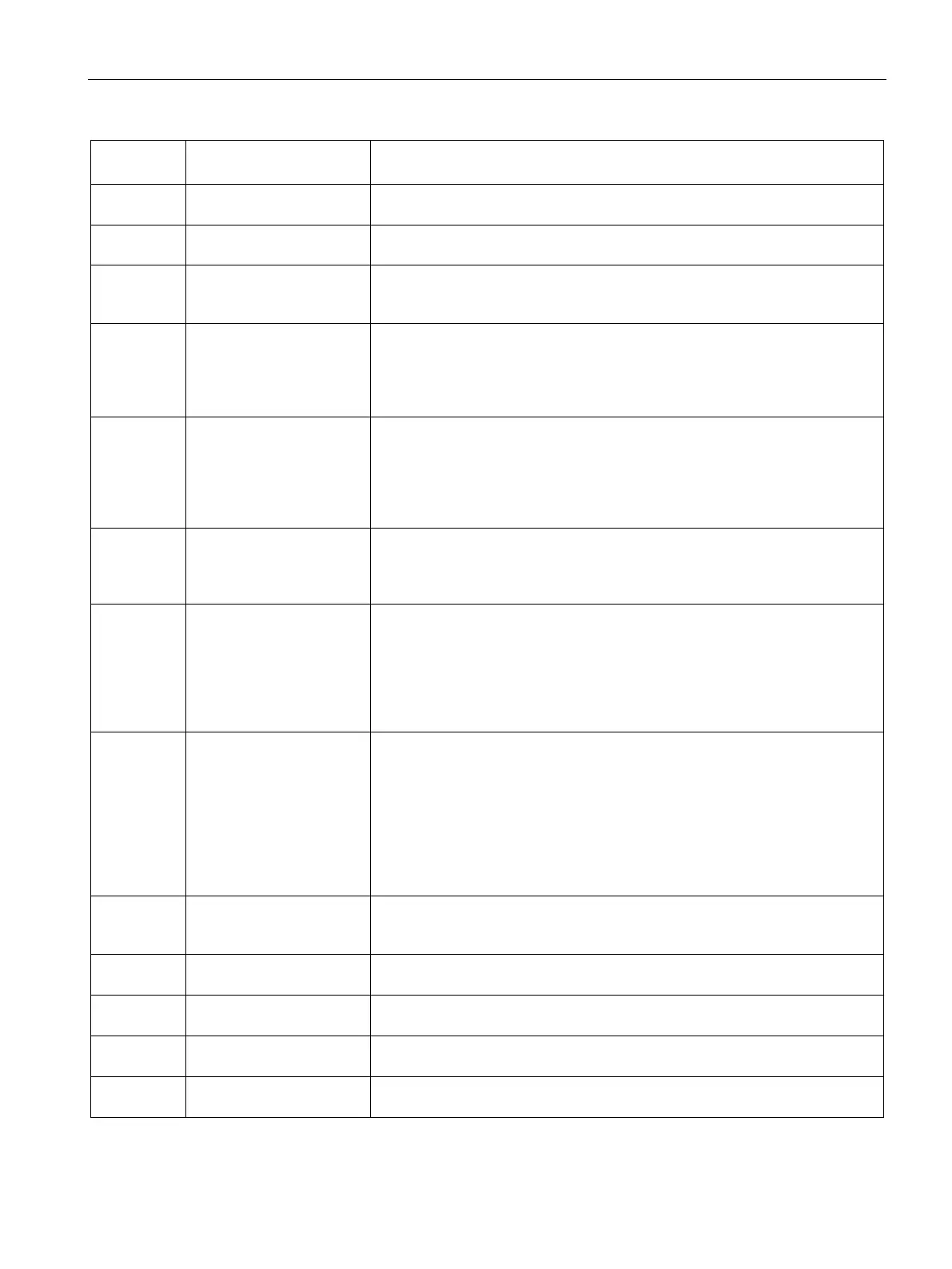

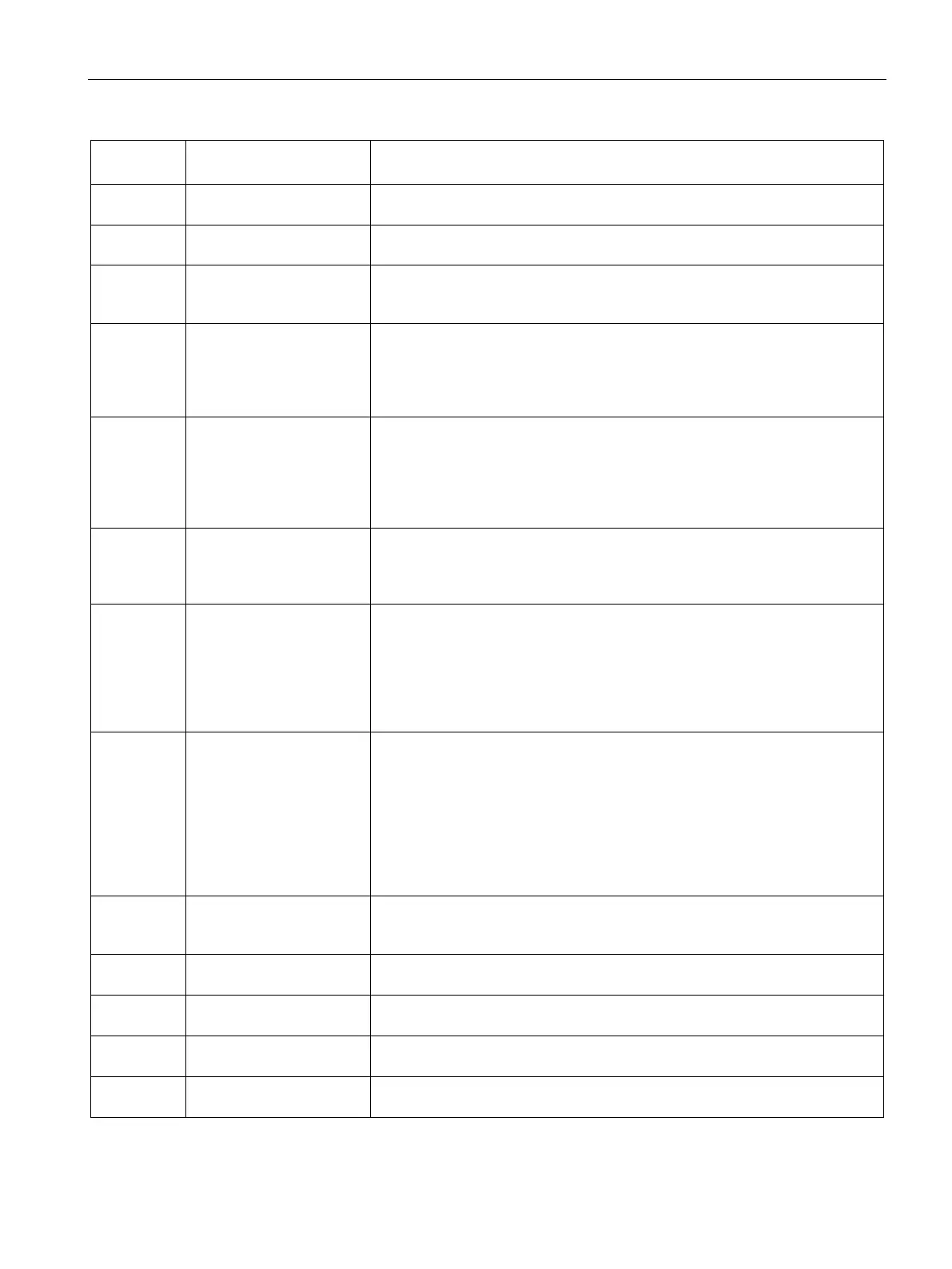

Command lists

10.2 Command lists

SIWAREX WT241

Manual, 05/2015, A5E36046748A 89

Start span calibration us-

ing material batch

Command 67 must be sent before the material defined in data record 3 reach-

es the measuring point.

Stop span calibration using

material batch

Command 68 must be sent after the material defined in data record 3 has

completely passed the measuring point.

Calculate span calibration

point after material batch

Command 69 can be used after the commands 67 and 68 to calculate the

span calibration point. The result is initially entered in DR4 and can then be

imported into DR3 using command 89.

Start speed/pulse detec-

tion

The command is used in the case of belt scales without speed sensor to start

determination of the belt speed, or in the case of belt scales with speed sensor

to start calculation of the pulse constants. The basis in each case is an exactly

specified belt length in DR3. The command should be sent at the moment

when a belt marking passes a defined point.

Stop speed/pulse detec-

tion

The command is used in the case of belt scales without speed sensor to stop

detection of belt speed, or in the case of belt scales with speed sensor to stop

calculation of the pulse constants. The command should be sent at the mo-

ment when a belt marking passes a defined point. The result is initially entered

in DR4 and can then be imported into DR3 using command 85. The defined

number of belt revolutions in DR3 must be observed!

Start speed measurement

"belt loaded"

The command can be used in the case of belt scales without speed sensor in

order to start the speed measurement with the belt loaded (preferably with

nominal belt load). The command should be sent at the moment when a belt

marking passes a defined point.

Stop speed measurement

"belt loaded"

The command can be used in the case of belt scales without speed sensor in

order to stop the speed measurement with the belt loaded (preferably with

nominal belt load). The command should be sent at the moment when a belt

marking passes a defined point. The result (speed and average belt load in

percent) is initially entered in DR4 and can then be imported into DR3 using

command 86. The defined number of belt revolutions in DR3 must be ob-

served!

Enable belt revolution

detection on DI.1

If a proximity switch is used to detect the belt revolutions (digital input DI.1

must be parameterized for this purpose in DR7), detection of the switch signal

must first be released using command 74. Totalizing is then stopped, and the

module waits for the switch signal at the digital input in order to start the belt

revolution detection. The module then expects pulses from the switch at DI.1.

For example, 3 pulses are expected if 3 belt revolutions were specified in DR3.

Detection of the belt revolution is complete following the third pulse. The result

is initially entered in DR4 and can then be imported into DR3 using command

85.

Abort running calibra-

tion/zeroing/belt detec-

tion/speed measurement

All generated dynamic commands are aborted.

The numbers A and B from DR21 are multiplied together. The result is entered

in DR4.

The numbers A and B from DR21 are divided by each other. The result is

entered in DR4.

The nominal speed determined by the commands 70/71 is copied from DR4 to

DR3.

Apply speed parameters

"belt loaded"

The result of the commands 72/73 is copied from DR4 to DR3.

Loading...

Loading...