Scale parameters and functions of the belt scale

8.3 Menu 1.1 Basic parameters

SIWAREX WT241

64 Manual, 05/2015, A5E36046748A

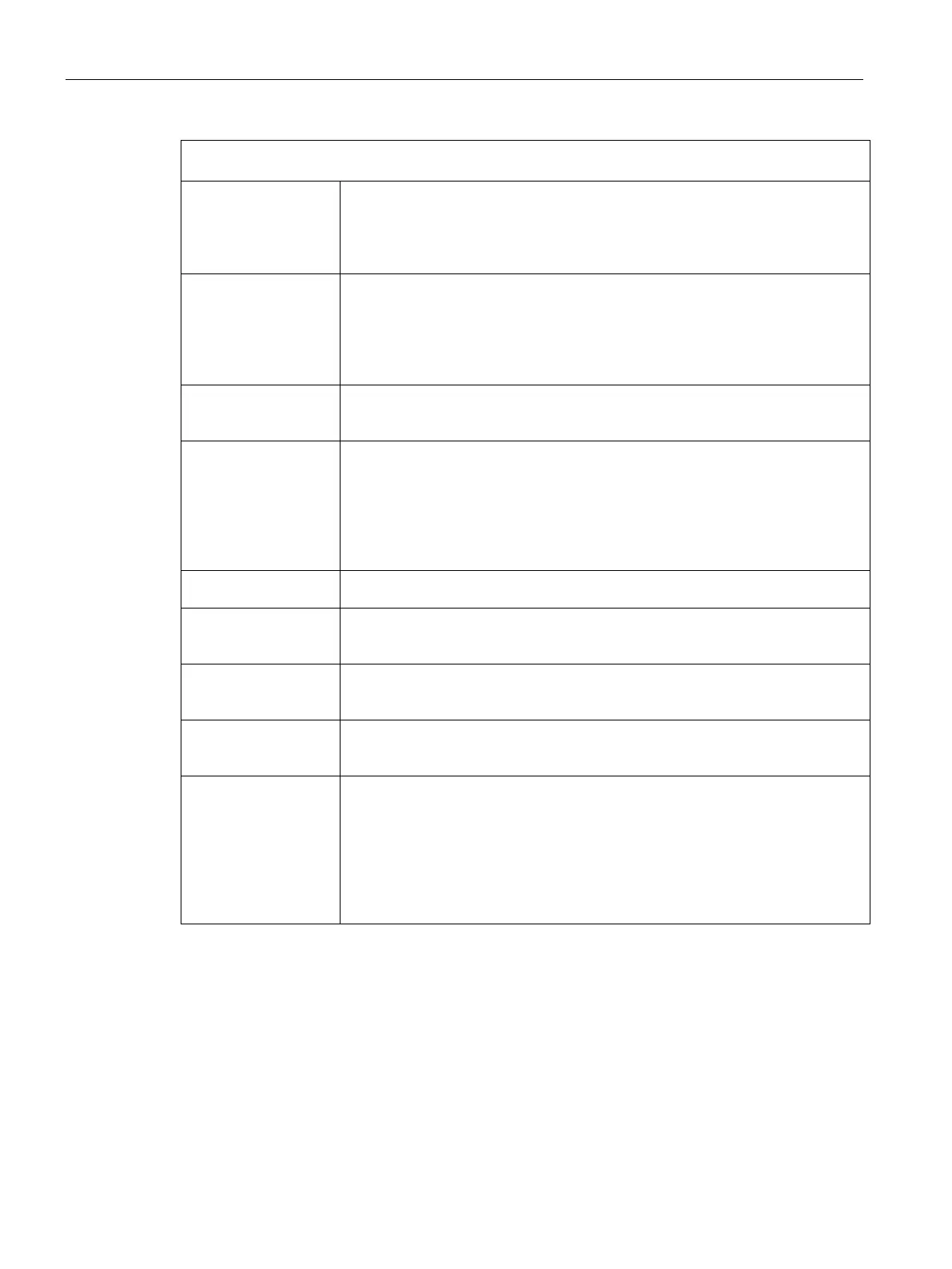

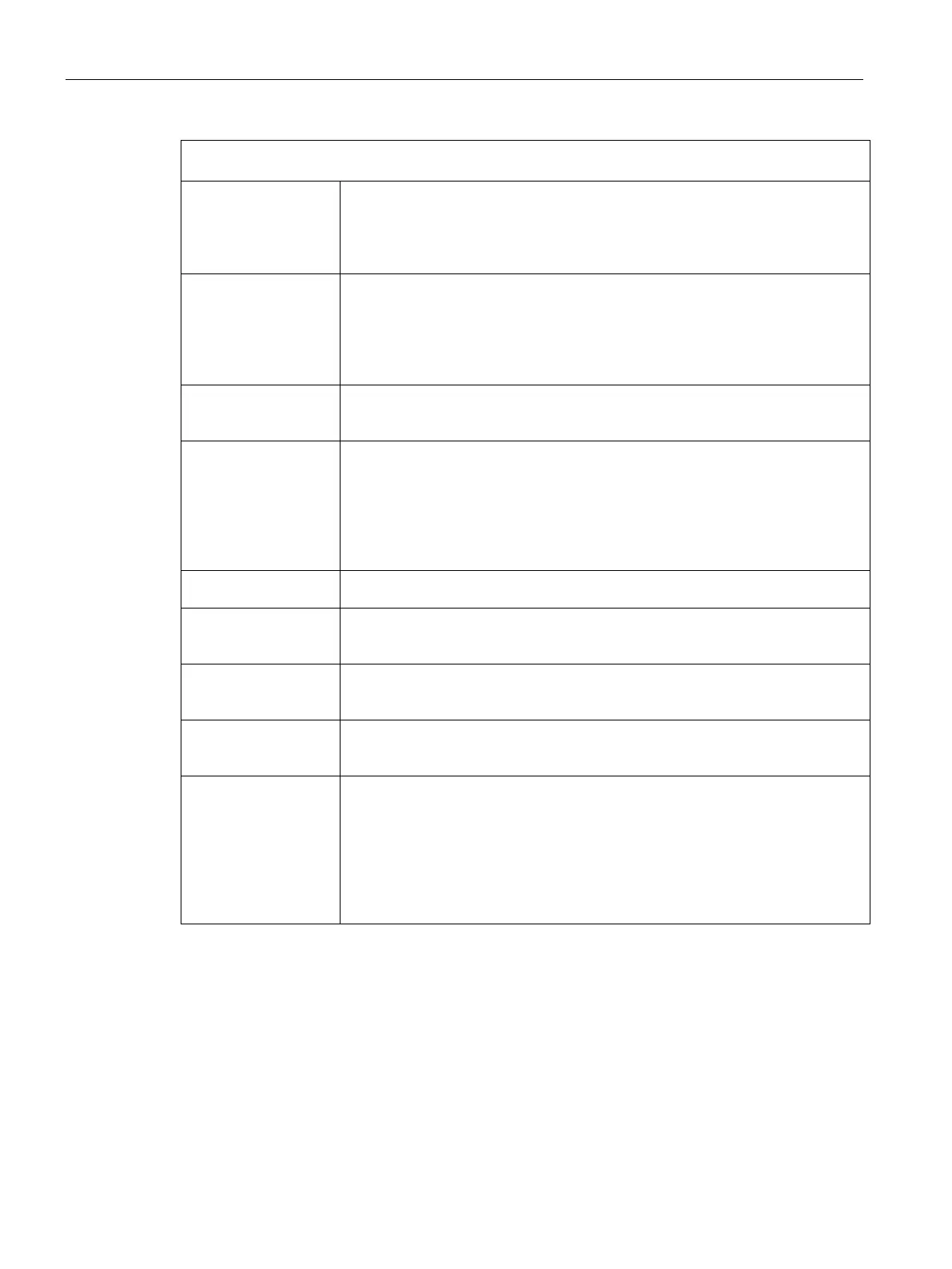

1.1.2 Basic parameter 2 of 2

Belt length (1 com-

plete revolution)

The length of the conveyor belt is measured during commissioning, and

entered. This is usually twice the distance between the axes of the de-

flection pulleys plus the single circumference of the pulley. The input is

made in the length unit from the belt load.

There are three options for determining the current speed:

0 – no speed sensor present. Specification of a constant belt speed or

determination of it.

1 – speed sensor at digital input DI.0

2 – external specification of belt speed from PLC via Modbus RTU (see

chapter 11 “Communication”, pg. 87.

Design / nominal

belt speed

The design speed can be determined with the belt empty. To this end,

the time for one or more belt revolutions is measured, and the speed

determined from this.

Speed correction if

belt loaded (Band

beladen)

If a speed sensor is not used (speed detection = 0, see above), a speed

correction can be determined at a certain belt load factor (preferably the

nominal load) in addition to the design speed. A load-dependent charac-

teristic for the speed then results together with the design speed. This

characteristic is determined by two working points: Design speed with

empty belt and a speed factor correction with a certain belt load factor.

The specification is made in % of the design speed.

Load factor for

speed correction

The associated belt load factor (in % of nominal load) is specified for

determination of the speed correction (see above)

The design speed can be determined with the belt empty. To this end,

the time for one or more belt revolutions is measured, and the speed

determined from this.

Belt revolutions for

calibration / zero

setting

At least one belt revolution is required for the calibration. You can in-

crease the number of belt revolutions in order to increase the accuracy

of the equipment.

Following switching-on of the electronic weighing system, this input indi-

cates in the status area that the time has not yet expired ("Warm-up

time running").

The weighing electronic offers three modes of simulation:

1. Load simulation

2. Speed simulation

3. Load and speed simulation

Without enabling one of these modes within the basic parameters, a

simulation cannot be started.

In case one simulation mode is chosen, the menu “1.5.9 Simulation” will

get accessable.

Loading...

Loading...