EN

11. Malfunctions

- 92 -

951-180-083-EN

Version 01

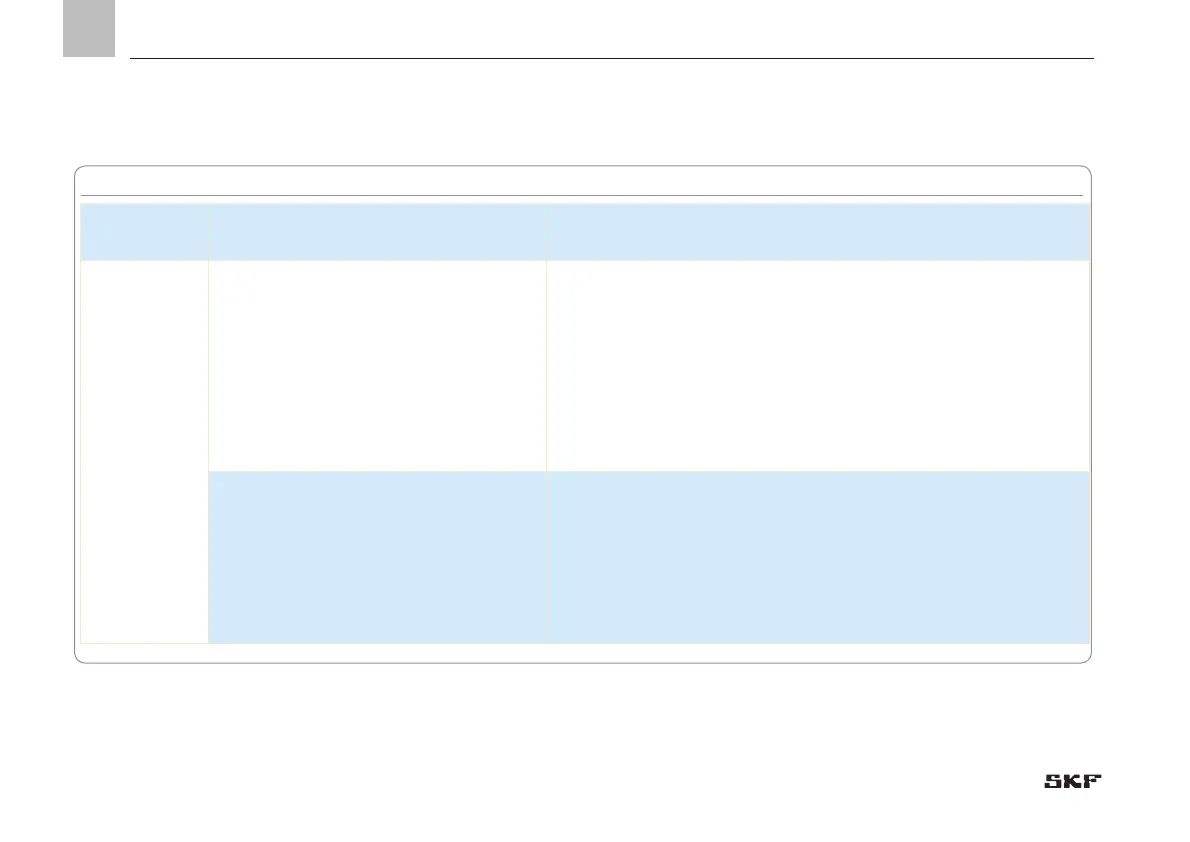

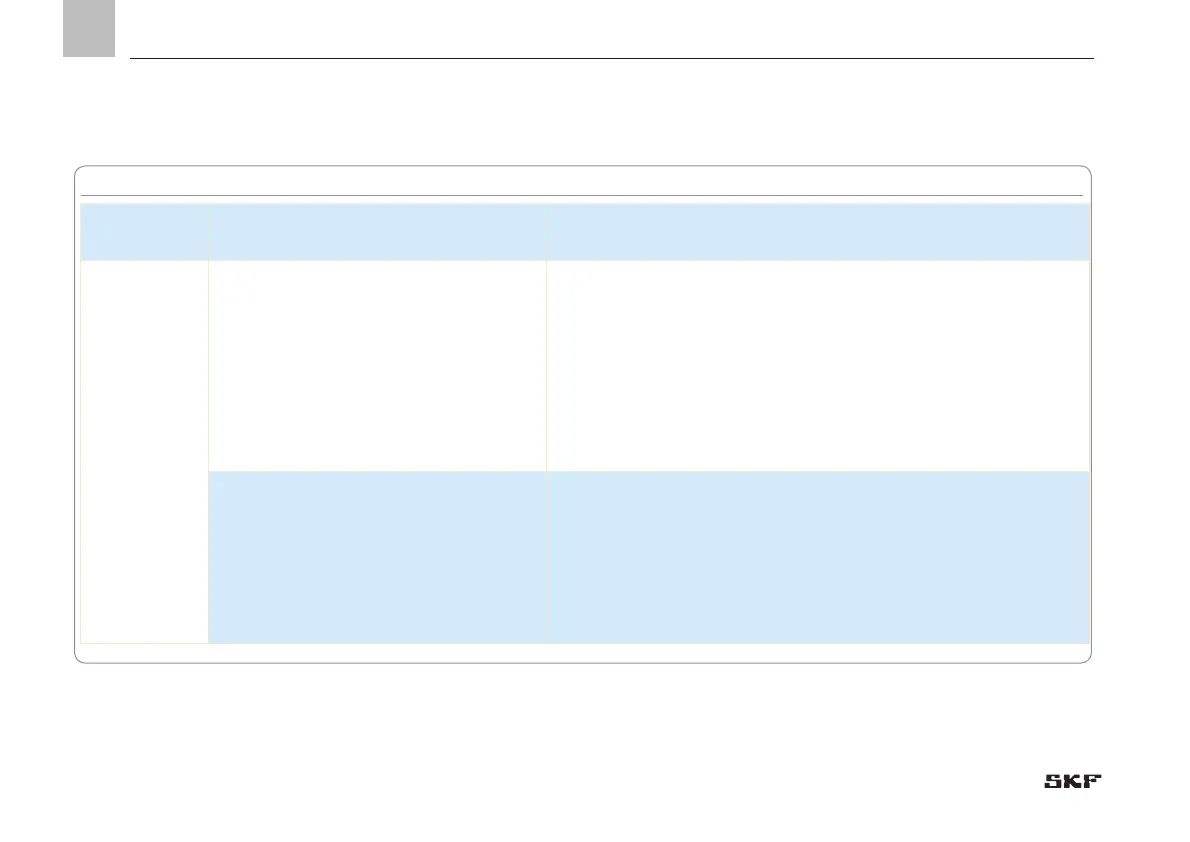

Fig. 42 Malfunctions table 3

Malfunction Possible cause Remedy

No lubricant at

lubrication points

Defective lubrication point

Defective bearing

Bearing bush twisted

Check bearing for mechanical damage or contamination.

Check bearing for proper function (move the machine and check for bearing noise).

Use a high-pressure grease gun to make the bearing move freely.

If this is not possible, the bearing must be repaired or replaced by technical

personnel

Install all lines and fittings that were removed during troubleshooting.

Perform start-up and functional inspection.

System malfunction

Loosen both lubrication lines on the last metering section of the main metering

device, switch on the lubrication system, and check whether lubricant discharges

without bubbles. If lubricant discharges without bubbles, tighten both lubrication

lines and repeat the procedure on all secondary metering devices, starting from

the closest metering device. Vent the possibly defective feeder again; replace in the

event of reoccurrence.

If all metering devices function properly, check the electrical connection of the

inductive NAMUR sensor for proper function.

Loading...

Loading...