HRX-OM-M090

Chapter 7 Control, Inspection and Cleaning

7.4 Stop for a Long Time HRS Series

7-6

7.4 Stop for a Long Time

If there is a concern that the product will not be operated for a long period of

time or there is a risk of freezing, conduct the following operations.

1. Turn off the user’s power supply (breaker).

2. Drain the circulating fluid and facility water (for water-cooled type) of the product

completely.

Please refer to ’’7.4.1 Discharge of the circulating fluid’’ for the method of drain the

circulating fluid from the product.

3. After draining, cover the product with vinyl, etc. and store.

7.4.1 Discharge of the circulating fluid and facility water

1. Place a container underneath the drain outlet.

(The capacity of the container should be approx. 10L.)

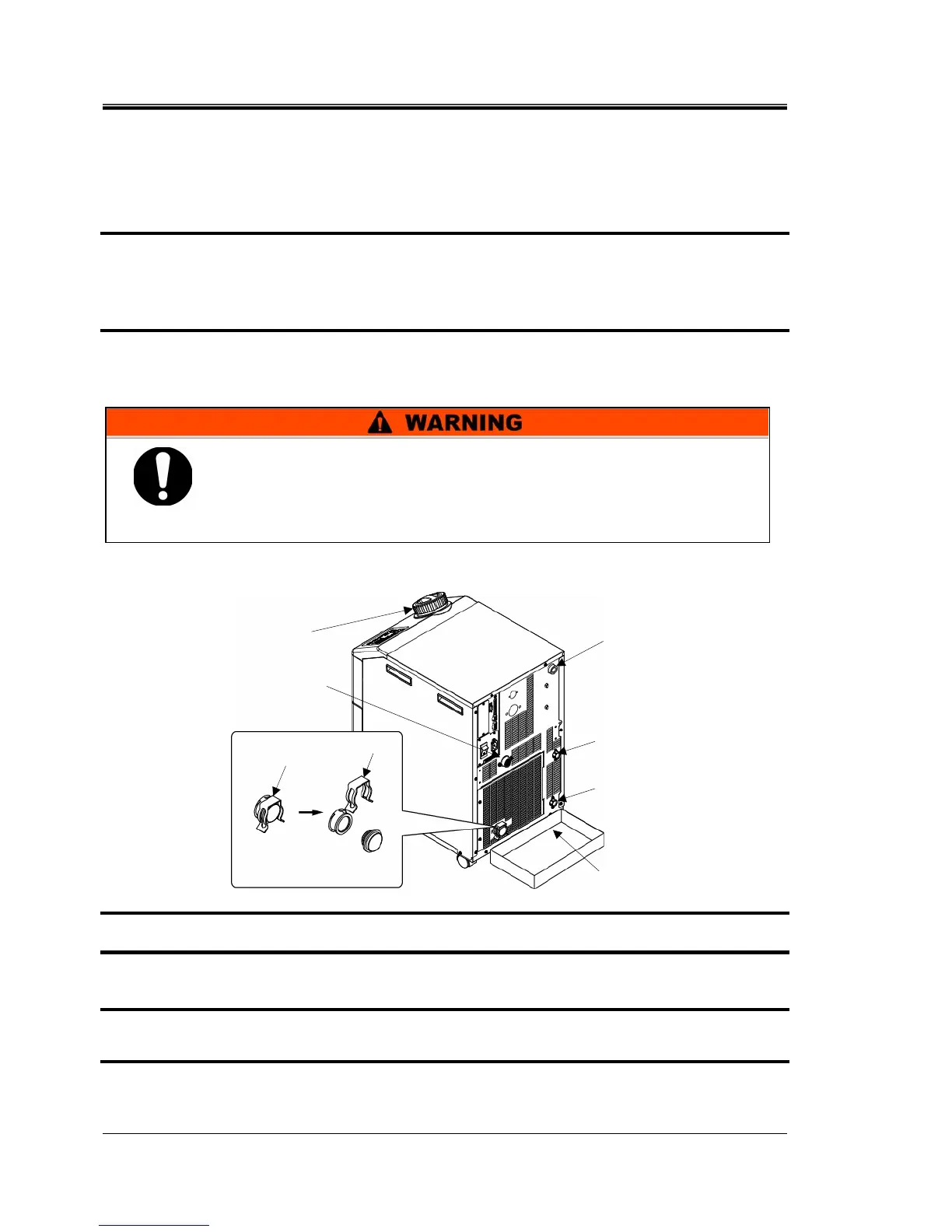

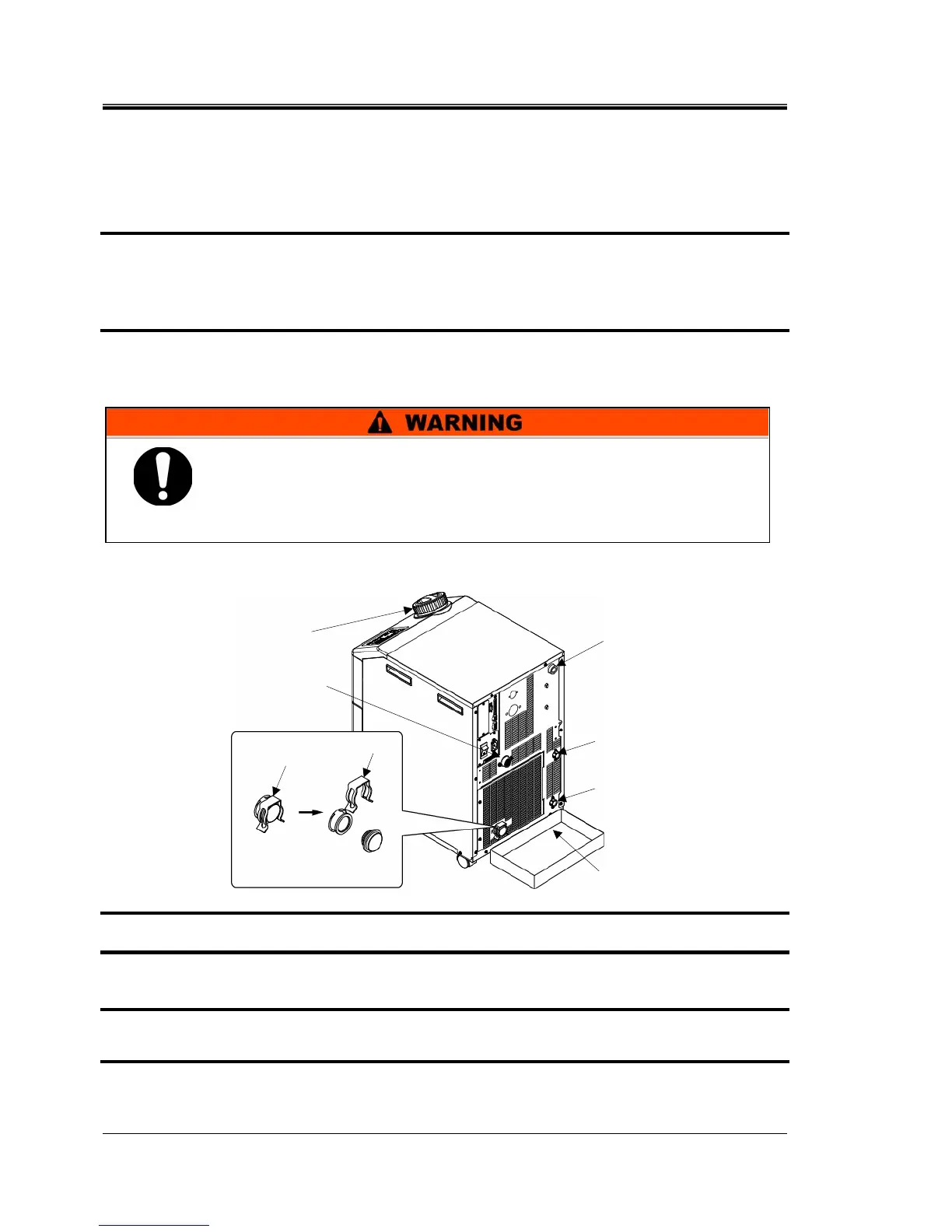

Fig. 7-4 Drain the circulating fluid and facility water from the product

2. Remove the tank lid.

3. Remove the drain plug on the drain port on the piping to discharge the fluid.

An O ring is used for the drain plug. Take care not to damage the O ring.

4. Confirm that a sufficient amount of the circulating fluid has been drained from the user’s

machine and piping, and apply air purge from the circulating fluid return port.

5. After discharging the circulating fluid in the tank, refit the drain plug, clip and close the

tank lid.

Drain port

Container

Clip

Drain plug

Normal

Liquid

discharge

Tank lid

Facility water outlet

(For water-cooled type)

Facility water inlet

(For water-cooled type)

Circulating

fluid outlet

Circulating fluid

return port

z Stop the customer device and release the residual pressure before

discharging the circulating fluid.

z Before discharging the facility water, in case of water-cooled

refrigerated type, stop the equipment for the facility water, or stop

the facility water circuit to release the residual pressure.

Loading...

Loading...