6-53

DCR-PC350/PC350E

3-3. SERVO AND RF SYSTEM ADJUSTMENT

Before perform the servo and RF system adjustments, check that

the specified value of “54 MHz/67.5 MHz Origin Oscillation

Adjustment” of “CAMERA SYSTEM ADJUSTMENT” is satisfied.

And check that the data of page: 0, address: 10 is “00”. If not, set

data: 00 to this address.

Note: The lens block (CD-537 board) must be connected when performing

the adjustments.

Adjusting Procedure:

1. CAP FG duty adjustment

2. Switching position adjustment

3. Error rate check

1. Cap FG Duty Adjustment (VC-370 Board)

Set the Cap FG signal duty cycle to 50% to establish an appropriate

capstan servo. If deviated, the uneven rotation of capstan and noise

can occur.

Measurement Point Display data of page: 3, address: 02, 03

Measuring Instrument Adjustment remote commander

Adjustment Page C

Adjustment Address 16

Specified Value Data of page: 3, address: 02 is “00”.

Data of page: 3, address: 03 is “00”.

Note1: The data of page: 0, address: 10 must be “00”.

Adjusting method:

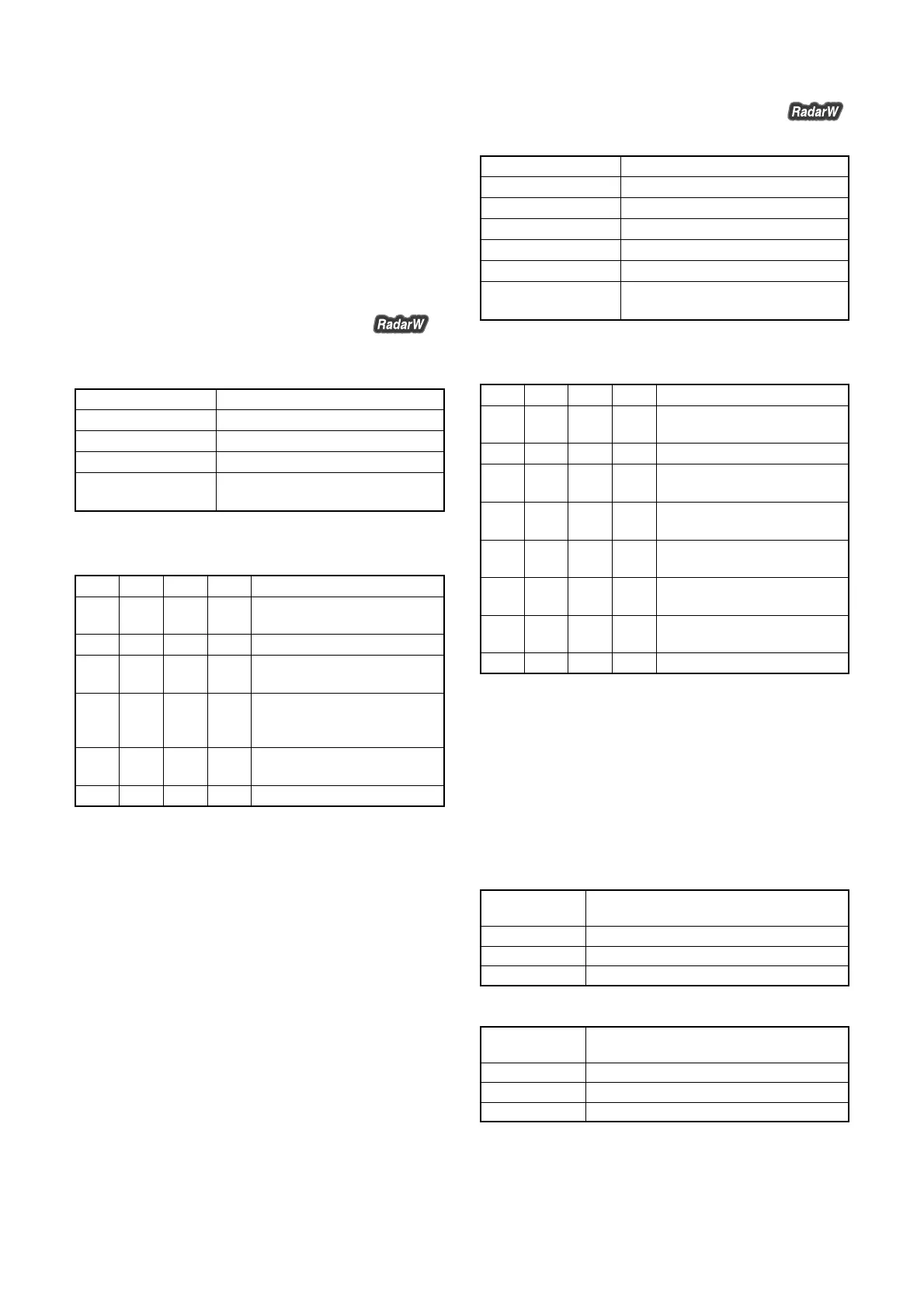

Order Page

Address

Data Procedure

1 Close the cassette compartment

without inserting a cassette.

2 0 01 01 Set the data.

3 3 01 1B Set the data, and press PAUSE

button.

4 3 02 Check that the data changes in

the following order.

“1B” → “2B” → “00”

5 3 03 Check that the data is “00”.

(Note2)

6 0 01 00 Set the data.

Note2: If the data is “01”, adjustment has errors or the mechanism deck is

defective.

2. Switching Position Adjustment (VC-370 Board)

To obtain normal playback waveform output during the playback

mode, adjust the switching position.

Mode VTR playback (PLAY/EDIT)

Signal SW/OL reference tape (XH2-3)

Measurement Point Display data of page: 3, address: 02, 03

Measuring Instrument Adjustment remote commander

Adjustment Page C

Adjustment Address 10, 11, 12, 13

Specified Value Data of page: 3, address: 02 is “00”.

Data of page: 3, address: 03 is “00”.

Note1: The data of page: 0, address: 10 must be “00”.

Adjusting method:

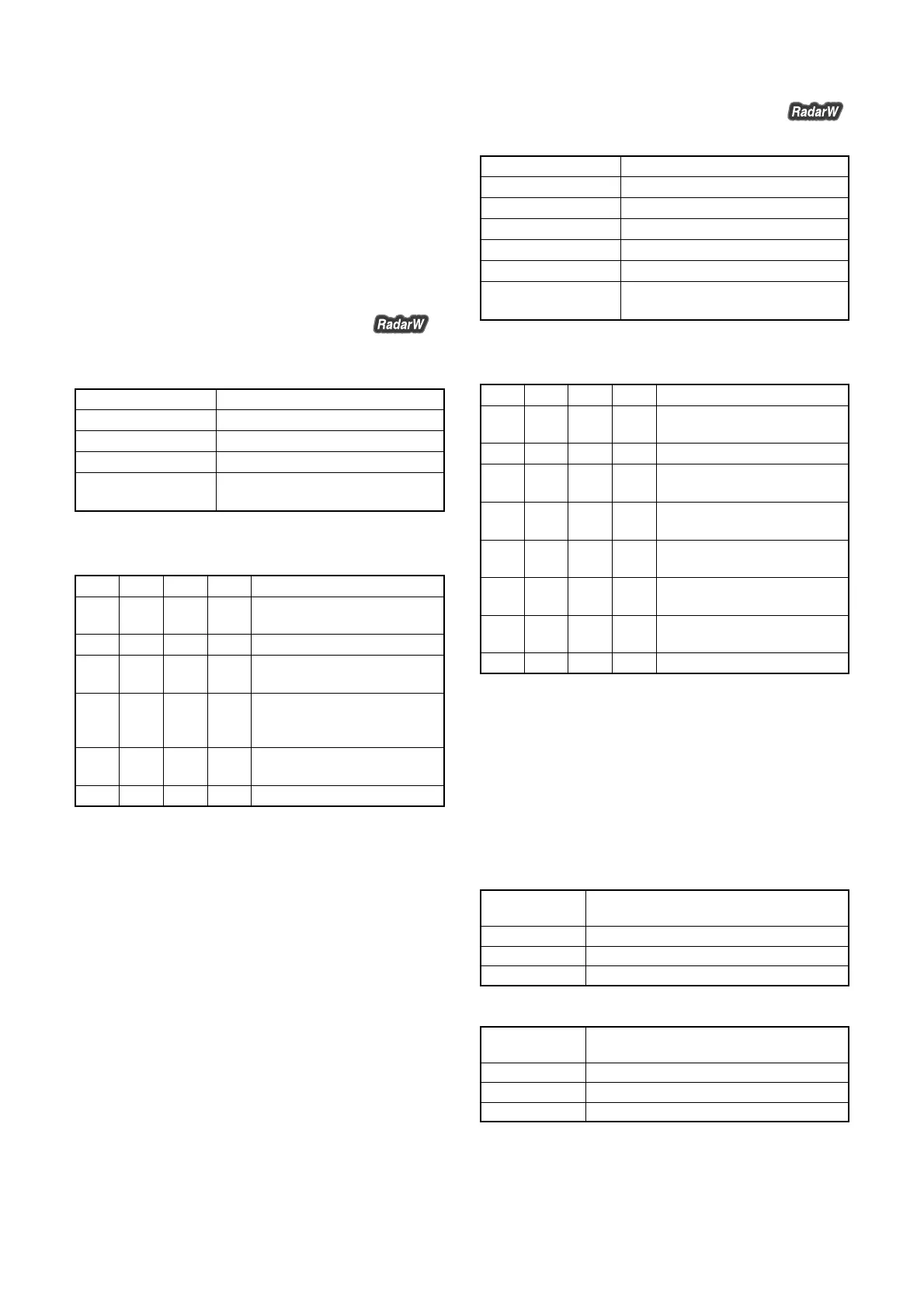

Order Page

Address

Data Procedure

1 Insert the SW/OL reference tape

and enter the VTR STOP mode.

2 0 01 01 Set the data.

3 C 10 EE Set the data, and press PAUSE

button.

4 3 21 Check that the data is “02”.

(Note2)

5 3 01 0D Set the data, and press PAUSE

button.

6 3 02 Check that the data changes to

“00”.

7 3 03 Check that the data is “00”.

(Note3)

8 0 01 00 Set the data.

Note2: If the data of page: 3, address: 21 is “72”, the tape top being played.

After playing the tape for 1 to 2 seconds, stop it, perform step 5

and higher.

If the data of page: 3, address: 21 is “62”, the tape end being played.

After rewinding the tape, perform step 5 and higher.

Note3: If bit 0 of the data is “1”, the EVEN channel is defective. If bit 1 is

“1”, the ODD channel is defective. Contents of the defect is written

into page: C, addresses: 10 and 12. See the following table. (For

the bit values, refer to “6-4. SERVICE MODE”, “4-3. 4. Bit value

discrimination”. ) If bit 3 of the data is “1”, the tape end being

played, so rewind the tape and perform the adjustment again.

When the EVEN channel is defective

When the ODD channel is defective

Data of page: C,

address: 12

EE

E8

E7

Contents of defect

Writing into EEPROM (IC2602) is defective

Adjustment data is out of range

No data is returned from IC2301

Data of page: C,

address: 10

EE

E8

E7

Contents of defect

Writing into EEPROM (IC2602) is defective

Adjustment data is out of range

No data is returned from IC2301

Loading...

Loading...