57

Note the following items when laying out cables on site:

• The axial tension on PV connectors must not exceed 80 N. Avoid axial cable

stress on the connector for a long time during field wiring.

• Radial stress or torque must not be generated on PV connectors. It may cause

the connector waterproof failure and reduce connector reliability.

• Leave at least 50 mm of slack to avoid the external force generated by the cable

bending affecting the waterproof performance.

• Refer to the specifications provided by the cable manufacturer for the minimum

cable bending radius. If the required bending radius is less than 50 mm, reserve

a bending radius of 50 mm. If the required bending radius is greater than 50 mm,

reserve the required minimum bending radius during wiring.

6.6.1 PV Input Configuration

In Australia and New Zealand, ensure the DC power for any PV string never exceeds a cer-

tain level with regards to the string voltage to avoid derating:

≤ 12.5 kW if string voltage is lower than 500 V

≤ 10 kW if string voltage is between 500 V and 800 V

≤ 8 kW if string voltage is between 800 V and 1000 V

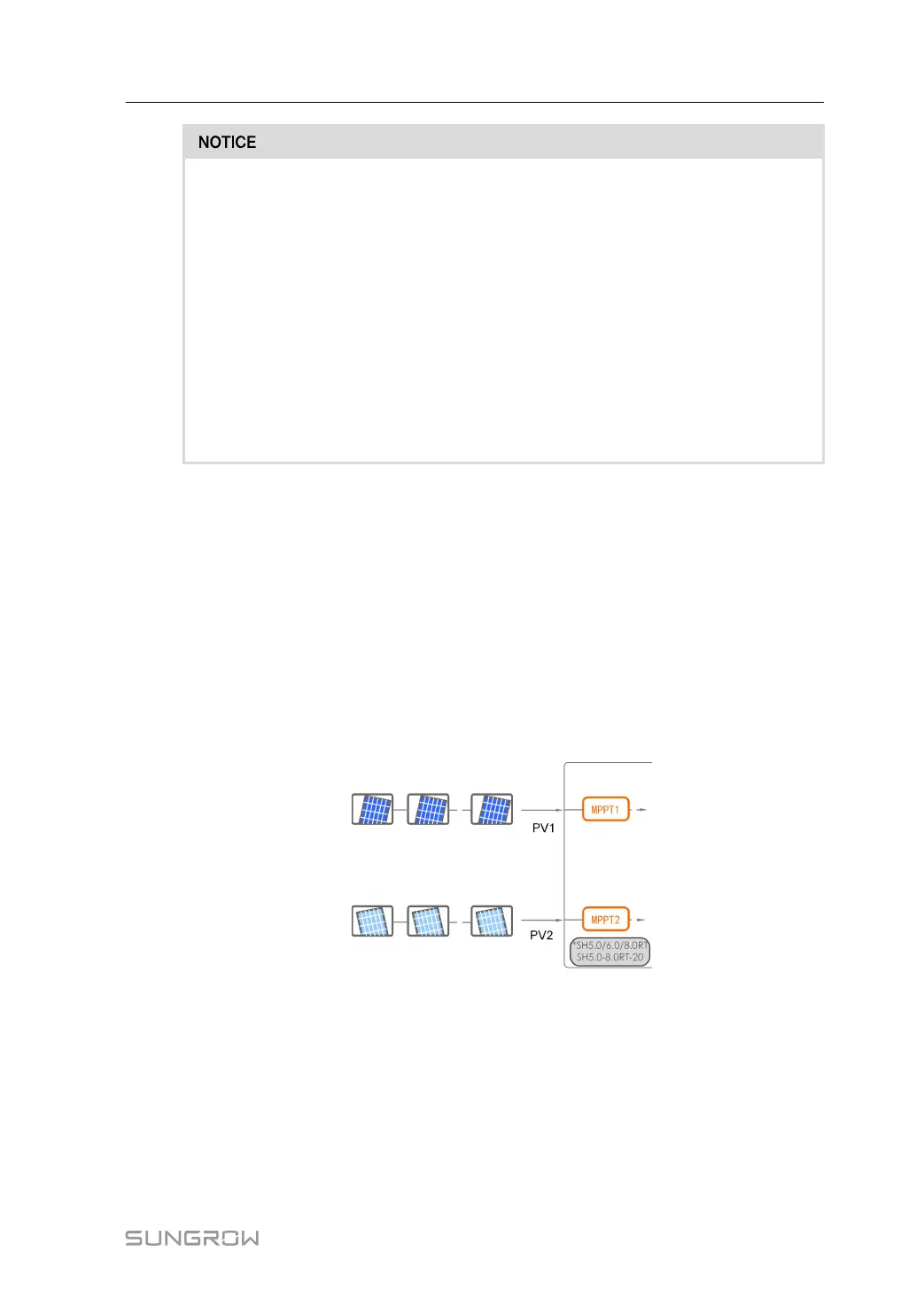

For SH5.0/6.0/8.0RT/SH5.0–8.0RT-20, each PV input operates independently and has its

own MPPT. In this way, string structures of each PV input may differ from each other, includ-

ing PV module type, number of PV modules in each string, angle of tilt, and installation

orientation.

For SH10RT/SH10RT-20, each pair of PV terminals is corresponding to an independent PV

string. PV input PV1 connect to MPPT1 and PV2, PV3 connect to MPPT2. For the best use

of PV power, PV2 and PV3 should be the same in PV string structure, including the type,

number, tilt, and orientation of the PV modules.

User Manual 6 Electrical Connection

Loading...

Loading...