SWL Series Skid Steer Loader

75

• Take into consideration that fuel is a flammable fluid. Clean the spilled fuel in

order to prevent risk of fire.

5.5.5.2 CHECK THE TIGHTENESS OF PUMP FIXING SCREWS

• Check and if necessary tighten the screws of the gear pump fixing point.

• Take as reference the driving torque shown in the following tables:

Driving Torque for Piston Pump Elastic

Coupler

Driving Torque for Gear Pump Piston

Pump

5.5.5.3 CHECKING THE FLUID LEVEL OF THE BATTERY

For checking the fluid level of the battery proceed as follow:

1) Open the plug on the topside of the battery.

2) Check the acid level. The acid level has to be 6 mm above the plate edge.

3) Refill with distilled water if necessary.

3) Put back and tighten the plug.

• Follow all the security regulation describes in the section 2.5.6.

• Park the machine on an level surface before checking the fluid level.

• In case you get in contact with the electrolyte, wash with plenty water and consult a

doctor.

• Grease the terminals with special anti-oxidation if they are oxidized.

5.5.5.4 CHANGING THE HYDRAULIC OIL FILTER

• Never change the hydraulic oil filter when the oil is warm.

• Used filters must be collected following the local regulation.

Proceed as follow for changing the hydraulic oil filter:

1) Remove the oil tank cap for releasing the remaining pressure inside the tank.

2) Remove the oil filter.

3) Renew the gasket when putting the new filter.

4) Put back the oil tank cap.

5.5.6 EVERY 1000 HOURS OF OPERATION

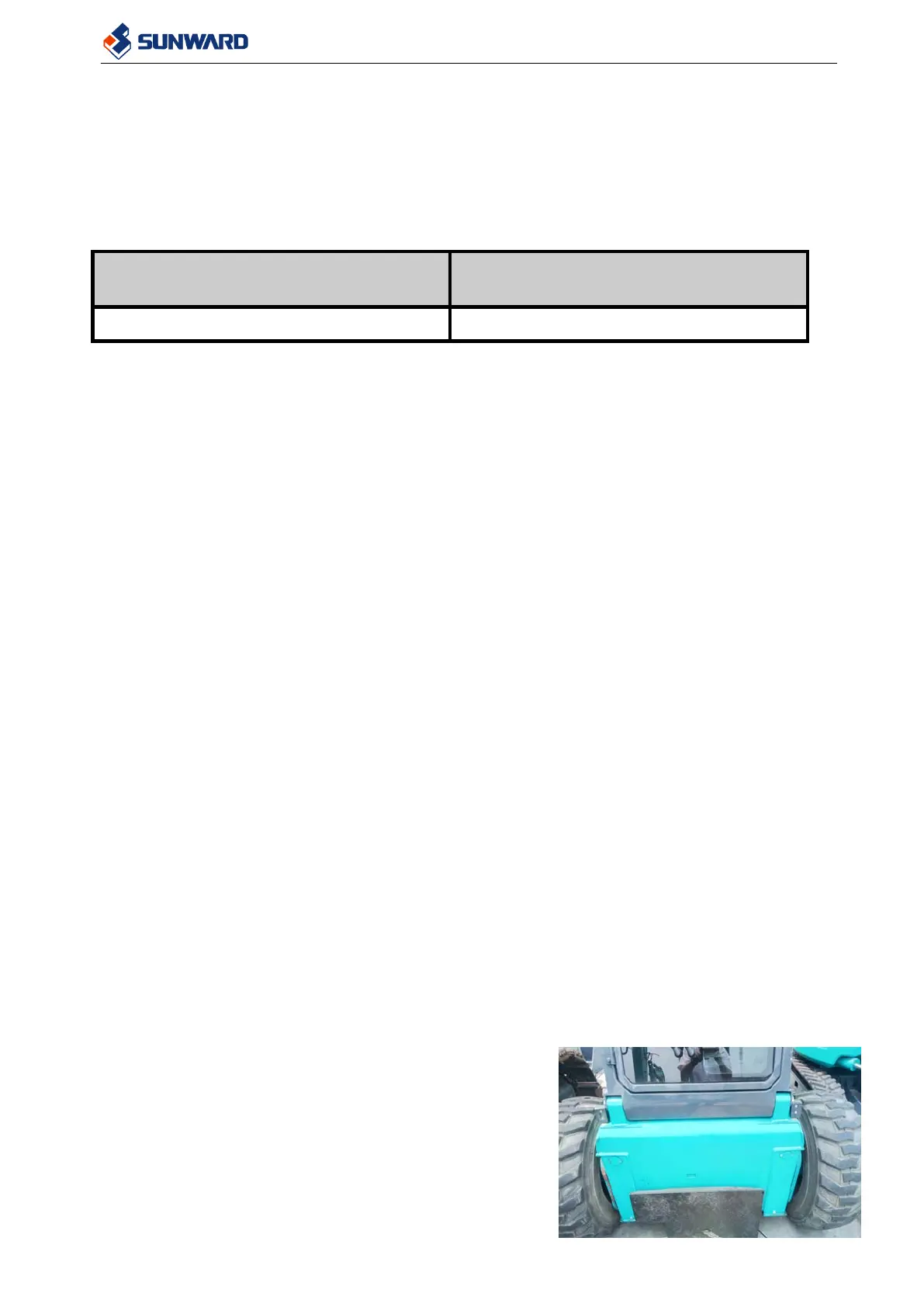

5.5.6.1 CHANGING THE OIL IN THE GEAR CHAIN BOX

Proceed as follow for draining the oil from the gear chain

box:

1) During the oil is hot (just after use the

machine) screw off the drain plug

located in the front part of the chassis

(see picture below).

2) While the oil’s draining screw off the

screw located on the top of the

chassis (see picture below).

Loading...

Loading...