74

M_T08_EN_B

Functions

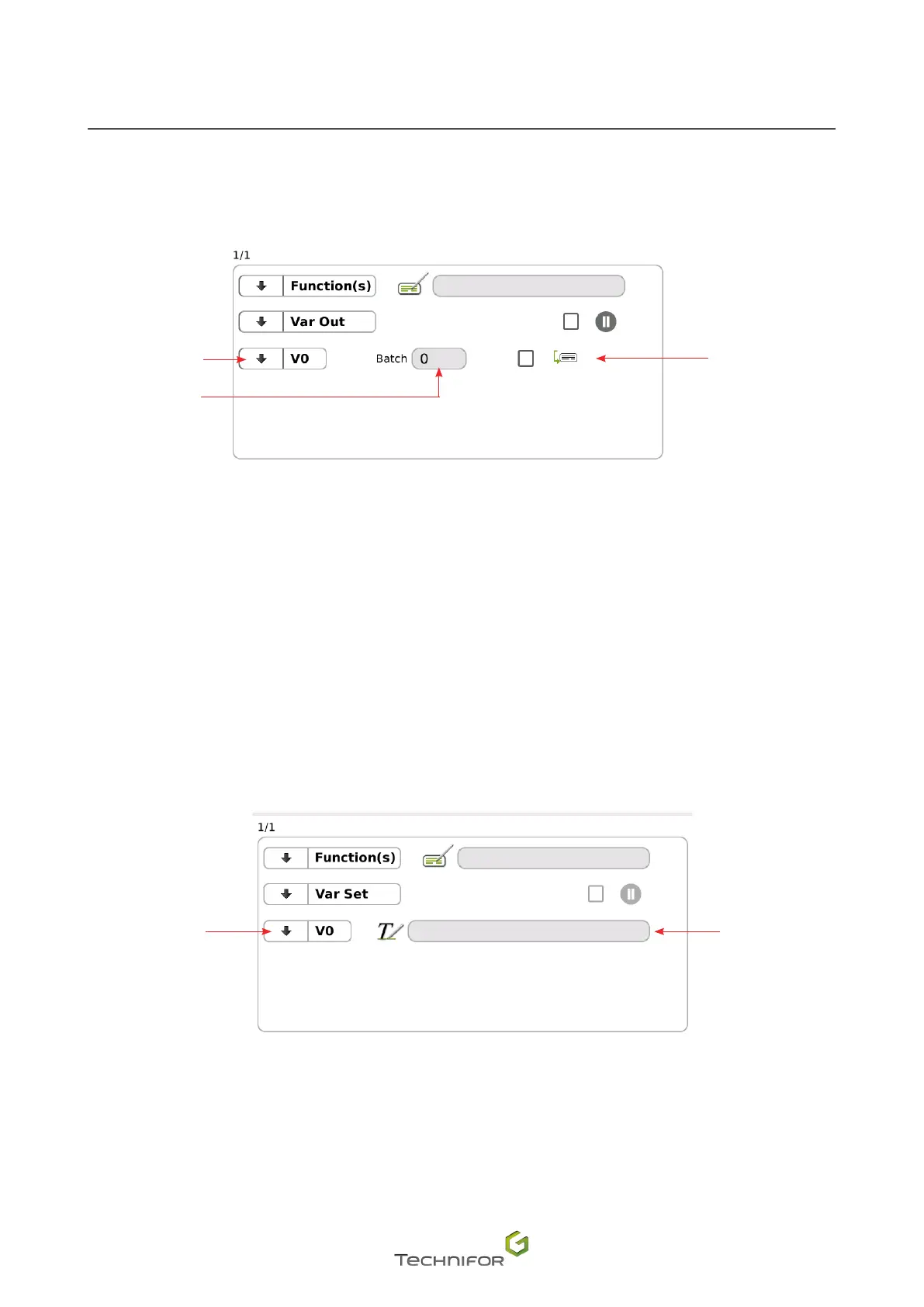

12. Var Out

Used to send a character string contained in a variable using a RS232 connection. The screen below appears:

1

2

3

1.

Number of the variable

2.

Enter batch size

3.

Activate / deactivate the carriage return (code 13) at the end of the string.

Select the number of the variable containing the character string to be sent.

Select the type of variable (le variable(s) / machine variable(s)).

Activate / deactivate the carriage return (code 13) at the end of the string: box ticked - This character is

appended to the end of the character string.

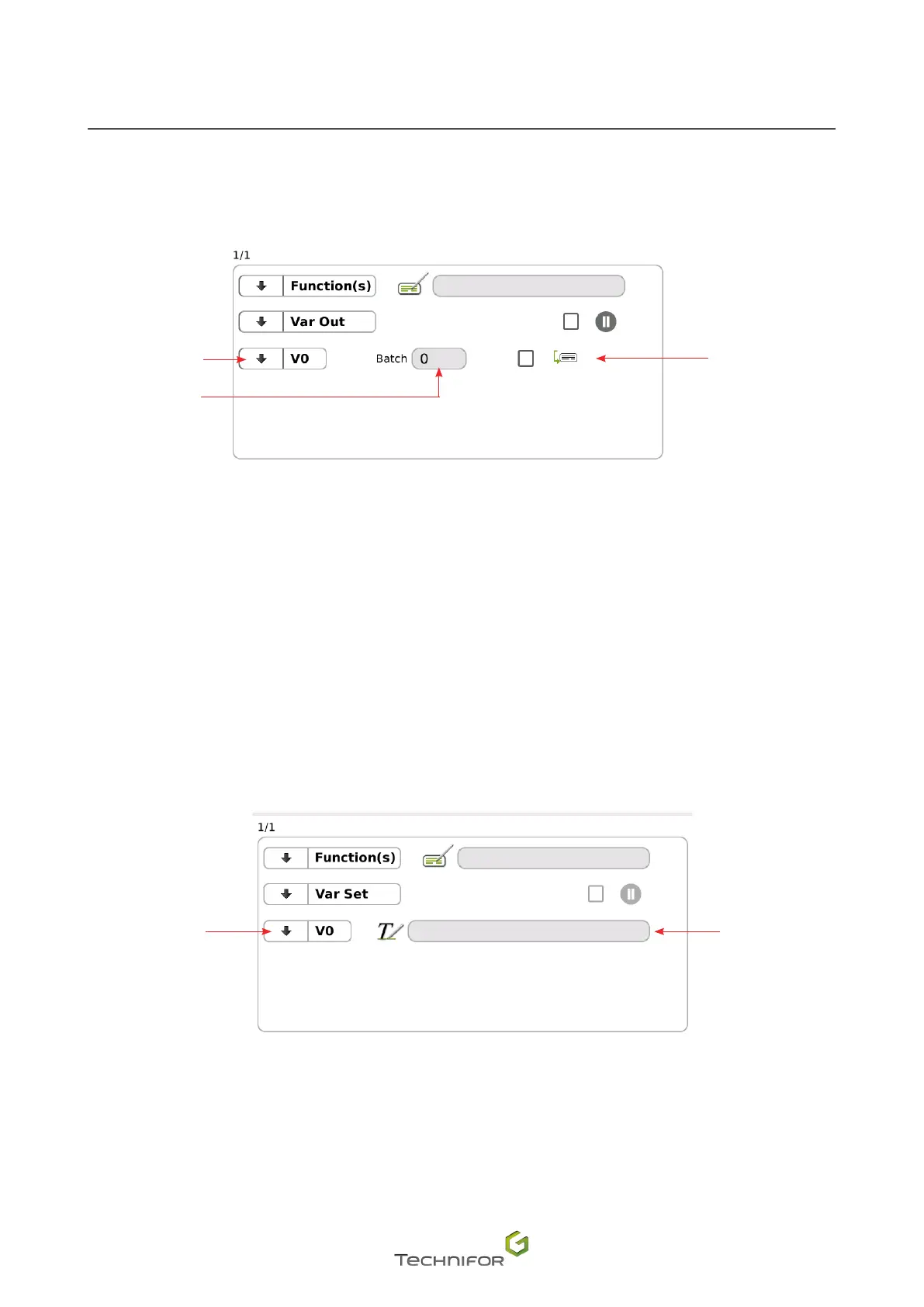

13. Var Set

Used to memorize a character string in a variable. The screen below appears:

1 2

1.

V: number of the variable in which the "Text" eld is saved, from V0 to V9

2.

Entering text in a selected variable

This eld may contain set text, key words (date, hour...), the content of a counter, etc.

Loading...

Loading...