TMS320F2810, TMS320F2811, TMS320F2812

TMS320C2810, TMS320C2811, TMS320C2812

SPRS174T –APRIL 2001–REVISED MAY 2012

www.ti.com

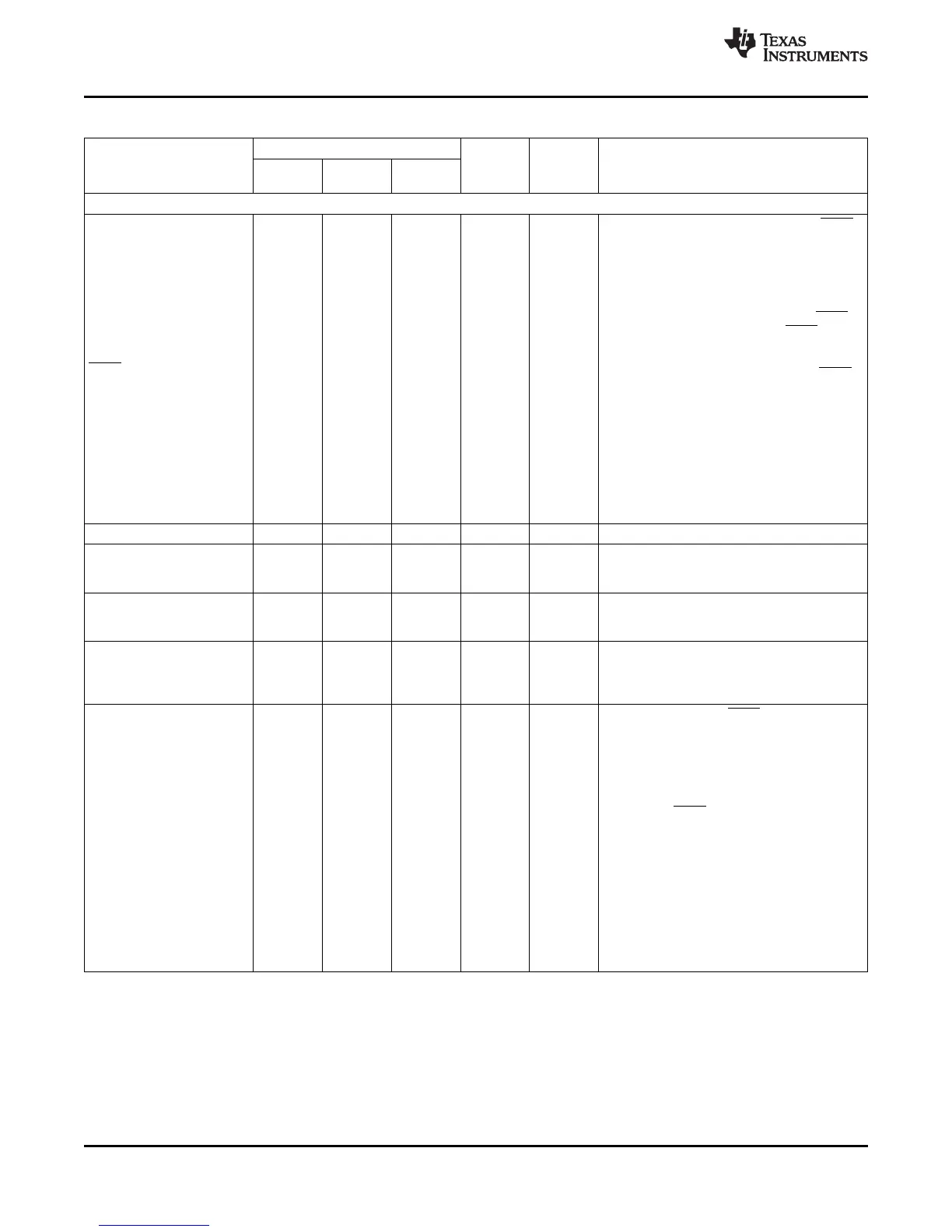

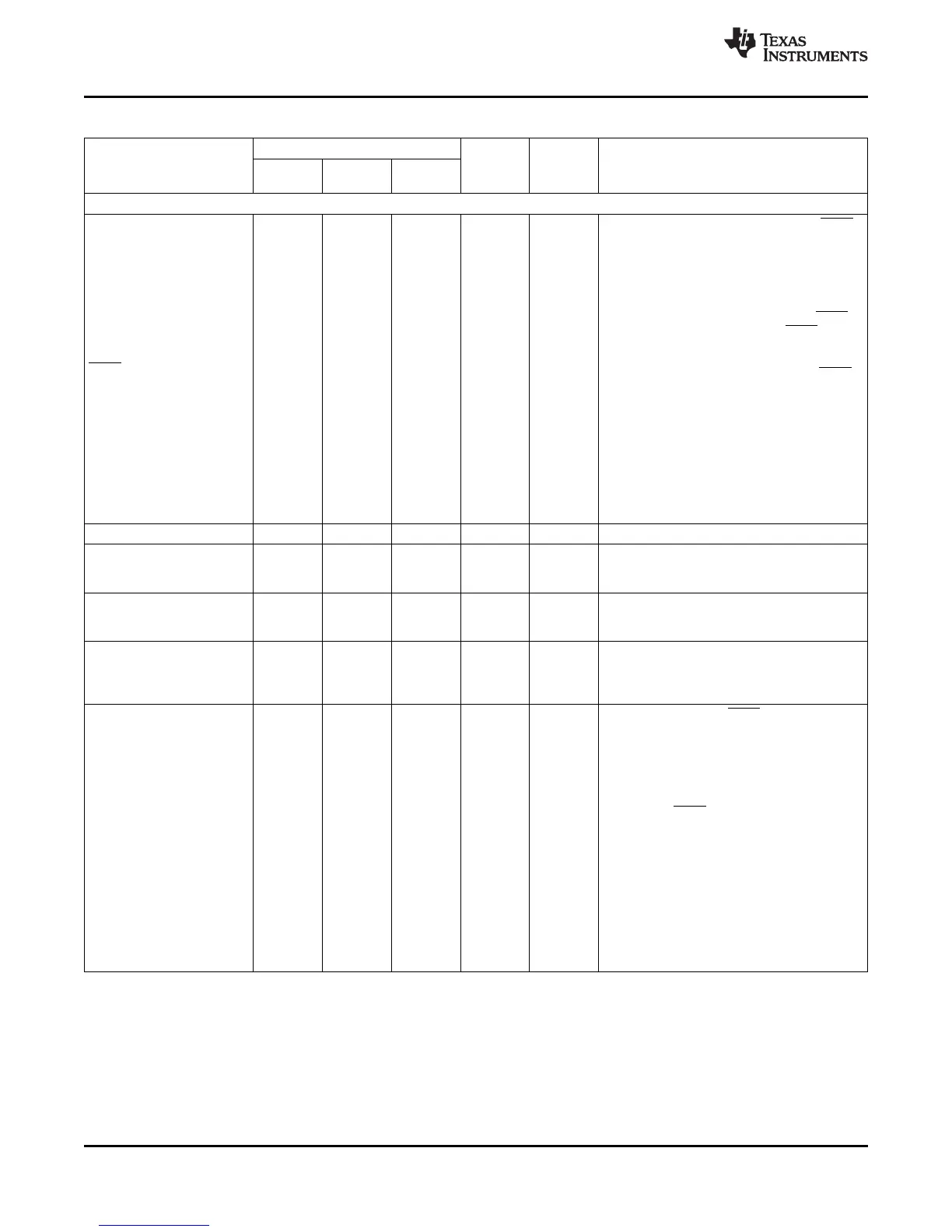

Table 2-2. Signal Descriptions

(1)

(continued)

PIN NO.

NAME I/O/Z

(2)

PU/PD

(3)

DESCRIPTION

179-BALL 176-PIN 128-PIN

GHH/ZHH PGF PBK

JTAG

JTAG test reset with internal pulldown. TRST,

when driven high, gives the scan system

control of the operations of the device. If this

signal is not connected or driven low, the

device operates in its functional mode, and the

test reset signals are ignored.

NOTE: Do not use pullup resistors on TRST; it

has an internal pulldown device. TRST is an

active-high test pin and must be maintained

low at all times during normal device

TRST B12 135 98 I PD

operation. In a low-noise environment, TRST

may be left floating. In other instances, an

external pulldown resistor is highly

recommended. The value of this resistor

should be based on drive strength of the

debugger pods applicable to the design. A 2.2-

kΩ resistor generally offers adequate

protection. Since this is application-specific, it

is recommended that each target board be

validated for proper operation of the debugger

and the application.

TCK A12 136 99 I PU JTAG test clock with internal pullup

JTAG test-mode select (TMS) with internal

TMS D13 126 92 I PU pullup. This serial control input is clocked into

the TAP controller on the rising edge of TCK.

JTAG test data input (TDI) with internal pullup.

TDI C13 131 96 I PU TDI is clocked into the selected register

(instruction or data) on a rising edge of TCK.

JTAG scan out, test data output (TDO). The

contents of the selected register (instruction or

TDO D12 127 93 O/Z –

data) is shifted out of TDO on the falling edge

of TCK.

Emulator pin 0. When TRST is driven high,

this pin is used as an interrupt to or from the

emulator system and is defined as input/output

through the JTAG scan. This pin is also used

to put the device into boundary-scan mode.

With the EMU0 pin at a logic-high state and

the EMU1 pin at a logic-low state, a rising

edge on the TRST pin would latch the device

into boundary-scan mode.

EMU0 D11 137 100 I/O/Z PU

NOTE: An external pullup resistor is

recommended on this pin. The value of this

resistor should be based on the drive strength

of the debugger pods applicable to the design.

A 2.2-kΩ to 4.7-kΩ resistor is generally

adequate. Since this is application-specific, it

is recommended that each target board be

validated for proper operation of the debugger

and the application.

20 Introduction Copyright © 2001–2012, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TMS320F2810 TMS320F2811 TMS320F2812 TMS320C2810 TMS320C2811 TMS320C2812

Loading...

Loading...