Refrigeration Maintenance

128

Set Up and Test of Evacuation

Equipment

NOTE: See the previous two pages for the

following discussion.

1. Connect the evacuation system to a 110 Vac

power supply. Connect a gauge manifold and

refrigerant supply to the charging port above

valve V-4. Turn the micron gauge On.

2. Close valves V-1, V-3 and V-4. Valve V-2 is

open.

3. Turn the vacuum pump On.

4. Open valve V-1 at the pump. The micron

gauge needle will move to the left. (See

micron gauge scale diagram—previous page).

NOTE: If the vacuum pump is okay, and

there are no leaks between V-1 and V-3, the

micron gauge should show less than 500

microns. If not, locate and correct the

problem.

5. With the pump still operating, open valve V-3.

If the micron reading does not return to a level

of less than 500 microns, locate and correct

the problem before continuing.

6. With the vacuum pump still operating, open

valve V-4. The micron level will rise

momentarily. If the micron reading does not

return to a level of less than 500 microns,

locate and correct the problem before

continuing.

7. Evacuate hoses to 100 microns or lowest

achievable level below 500 microns.

8. Once 100 microns is reached, close valve V-1

at the pump. Turn the vacuum pump Off.

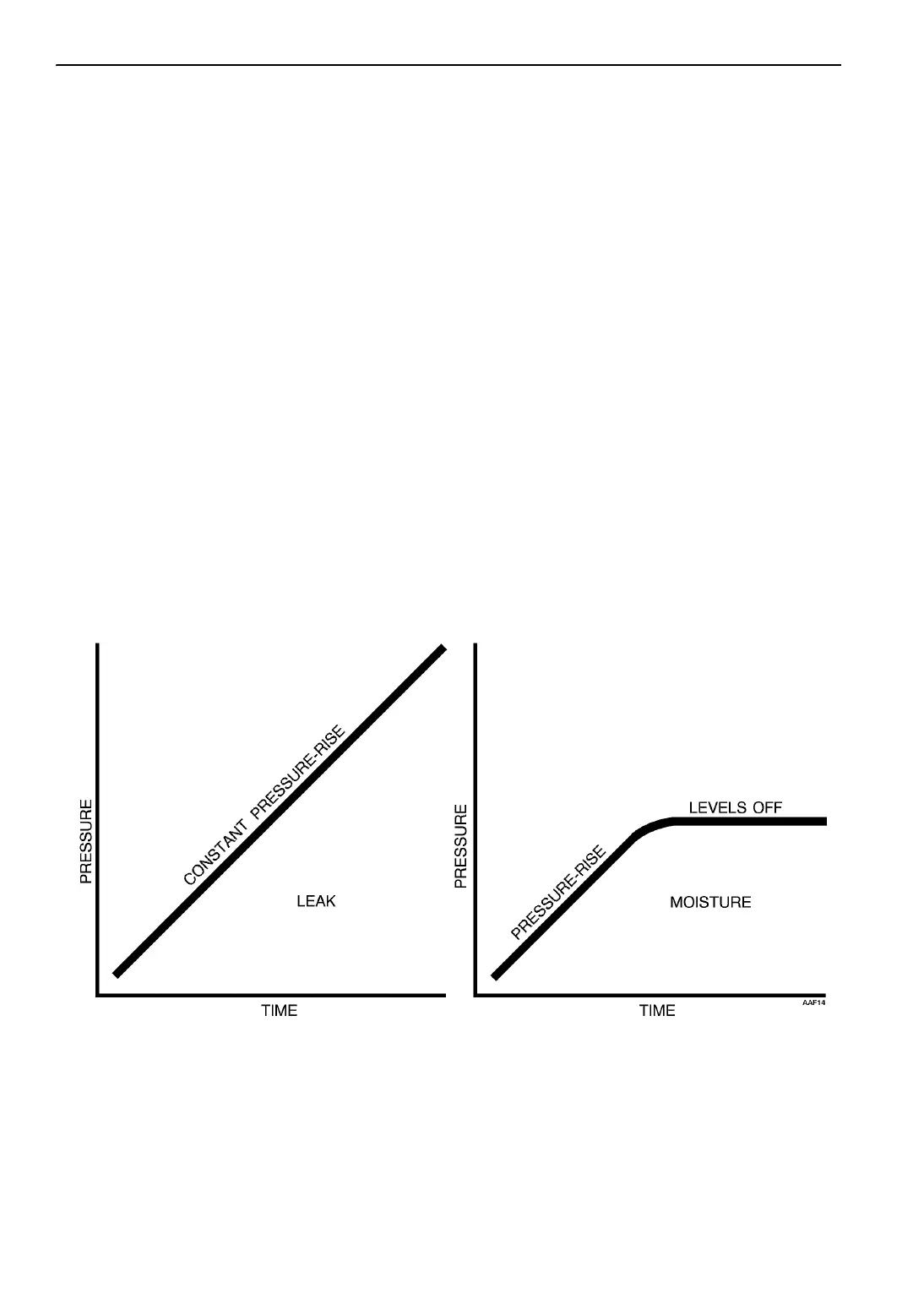

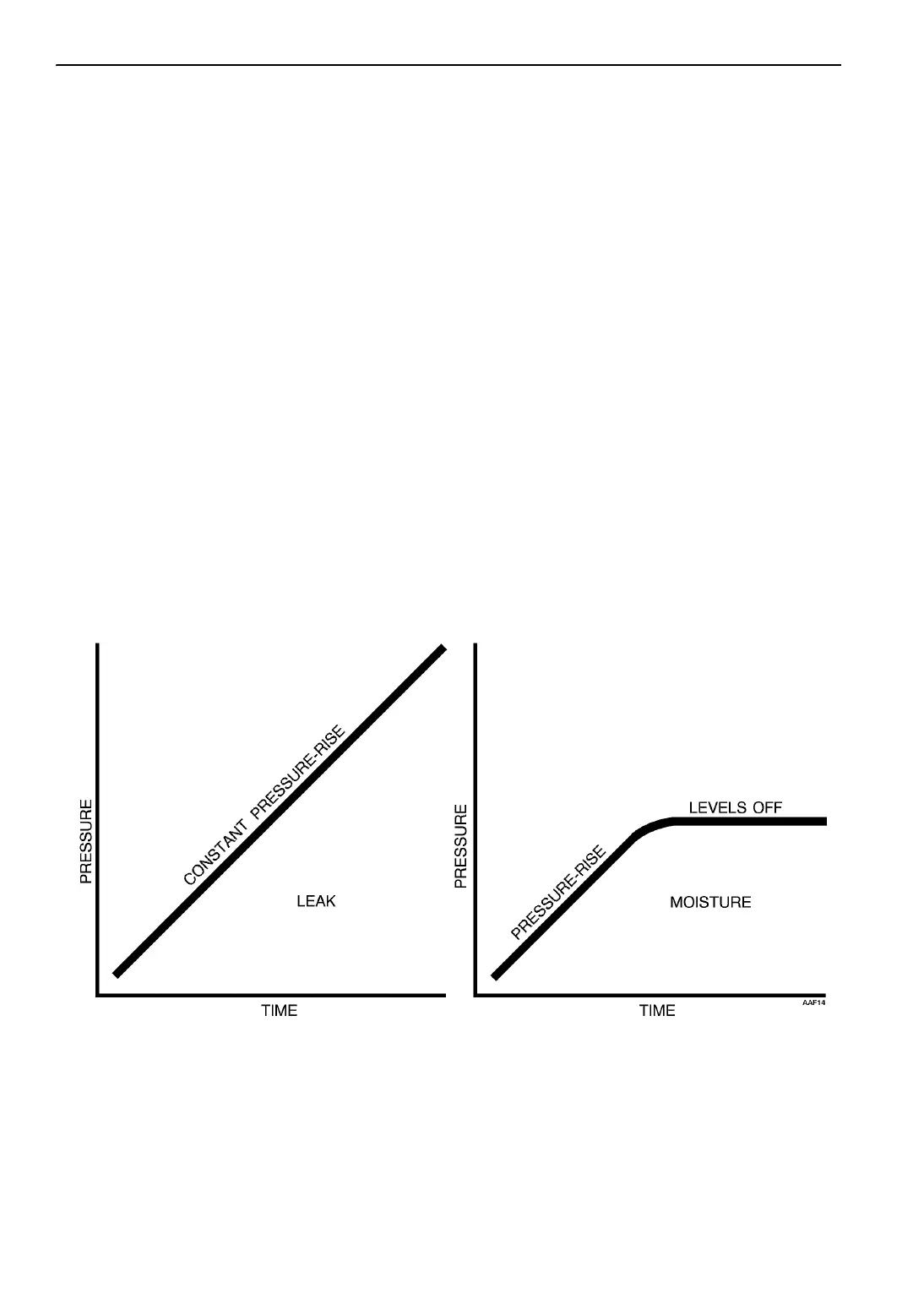

Figure 152: Pressure Rise Graphs

Leak

Isolate the pump from the system by closing the

proper valve. Watch the movement of the vacuum

gauge needle. If the needle continues to rise,

this is an indication that a leak exists in the unit

or the connecting line. The leak must then be

located and eliminated.

Moisture

Should the needle show a pressure rise but

finally level off to practically a constant mark,

this is an indication that the system is vacuum

tight but is still too wet, requiring additional

dehydration and pumping time.

Loading...

Loading...