Electrical Maintenance

85

NOTE: On installations where the unit is

connected to the truck battery and both units are

running—it is normal for the unit to indicate a

discharge condition while the truck engine is

running because of the truck’s higher voltage

charge rate.

Preheat Buzzer

The preheat buzzer module on the circuit board is

designed to indicate preheat is in operation.

RPM Sensor

The RPM sensor is in the engine bell housing

adjacent to, but not touching, the flywheel

(backed off 1/4 turn).

The RPM sensor is a device containing an

inductance coil and magnet. When the magnetic

field is distorted by the passing ring gear teeth, the

inductance coil generates an ac electrical signal

that has a voltage and frequency variation

proportional to the engine RPM.

By monitoring the frequency of this signal with

the microprocessor, the timing of the starter

disengagement can be precisely controlled.

If the RPM sensor fails, the starter may not

disengage or engage properly and a fault code will

be generated to the microprocessor.

Testing the RPM Sensor:

The following equipment is required:

• AC voltmeter capable of reading up to 10

volts

• Ohmmeter

The flywheel (RPM) sensor may be checked as

follows:

1. Install the flywheel (RPM) sensor into the

flywheel; bracket of the start-stop unit until it

contacts the ring gear. Back out the sensor 1/4

turn and tighten the locknut.

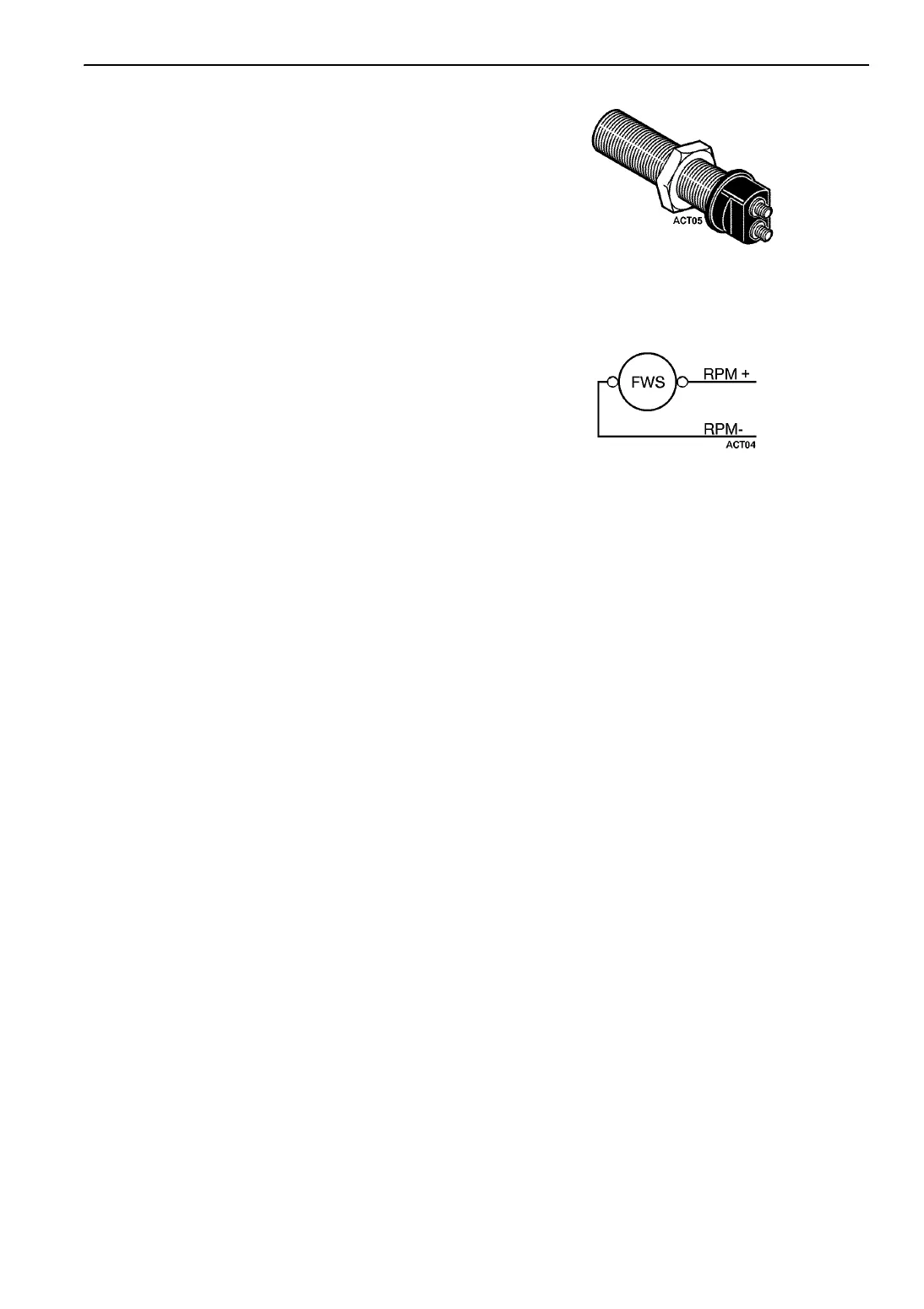

Figure 114: Flywheel (RPM) Sensor

2. Disconnect wires RPM+ and RPM- from the

sensor.

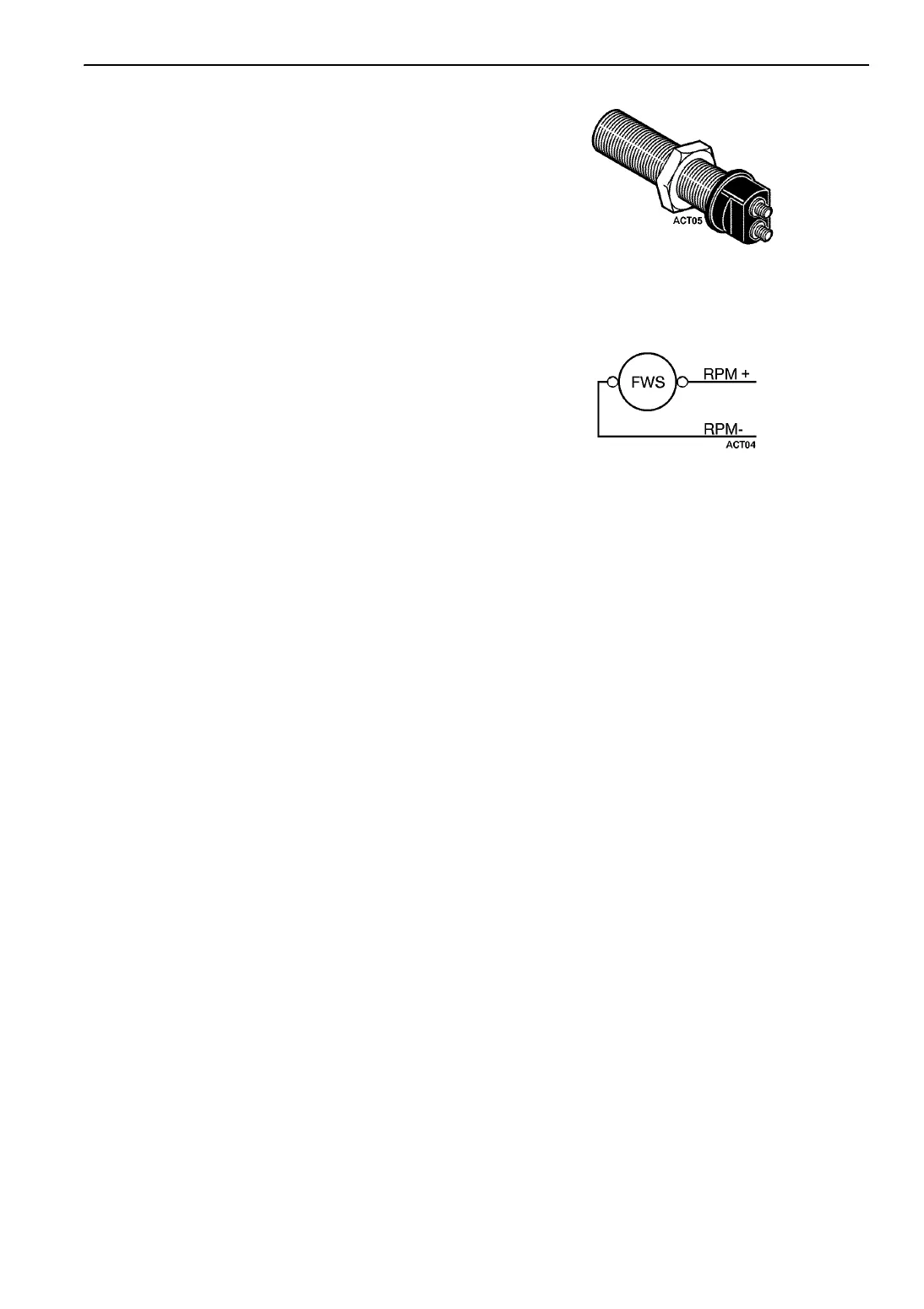

Figure 115: RPM+ and RPM- Wires

3. Place the unit in Continuous Run. Run the unit

on low speed and high speed. Check the AC

voltage output across the sensor terminals.

Use a meter with a high ohms per volt internal

resistance. A Simpson 260, Fluke digital or

any good VOM will work. However, an

automotive type meter may not give an

accurate reading because the meter may load

the circuit heavily and cause the voltage level

to appear lower than it actually is.

a. The output voltage should be 1.0 to

2.0 Vac on low speed.

b. The output voltage should be 2.0 to

2.5 Vac on high speed.

NOTE: If the voltage is slightly off, the

voltage may be increased by turning the

sensor in more, and the voltage may be

lowered by turning the sensor out more.

4. Reconnect RPM+ and RPM- wires on RPM

sensor.

If the RPM sensor passes the above test, the

sensor may be considered good.

If the unit is not available, an alternate less

reliable test may be performed as follows:

Disconnect the sensor from all wires, and measure

the resistance across the terminals and from each

terminal to the aluminum case. The resistance

Loading...

Loading...