91

Engine Maintenance

Engine Change

In the first quarter of 2005 the engines in these

units changed from a TK 3.95 to a TK376 to meet

EPA Tier 2 requirements.

The TK 3.95 is an EPA Tier 1 engine.

The TK376 is an EPA Tier 2 engine.

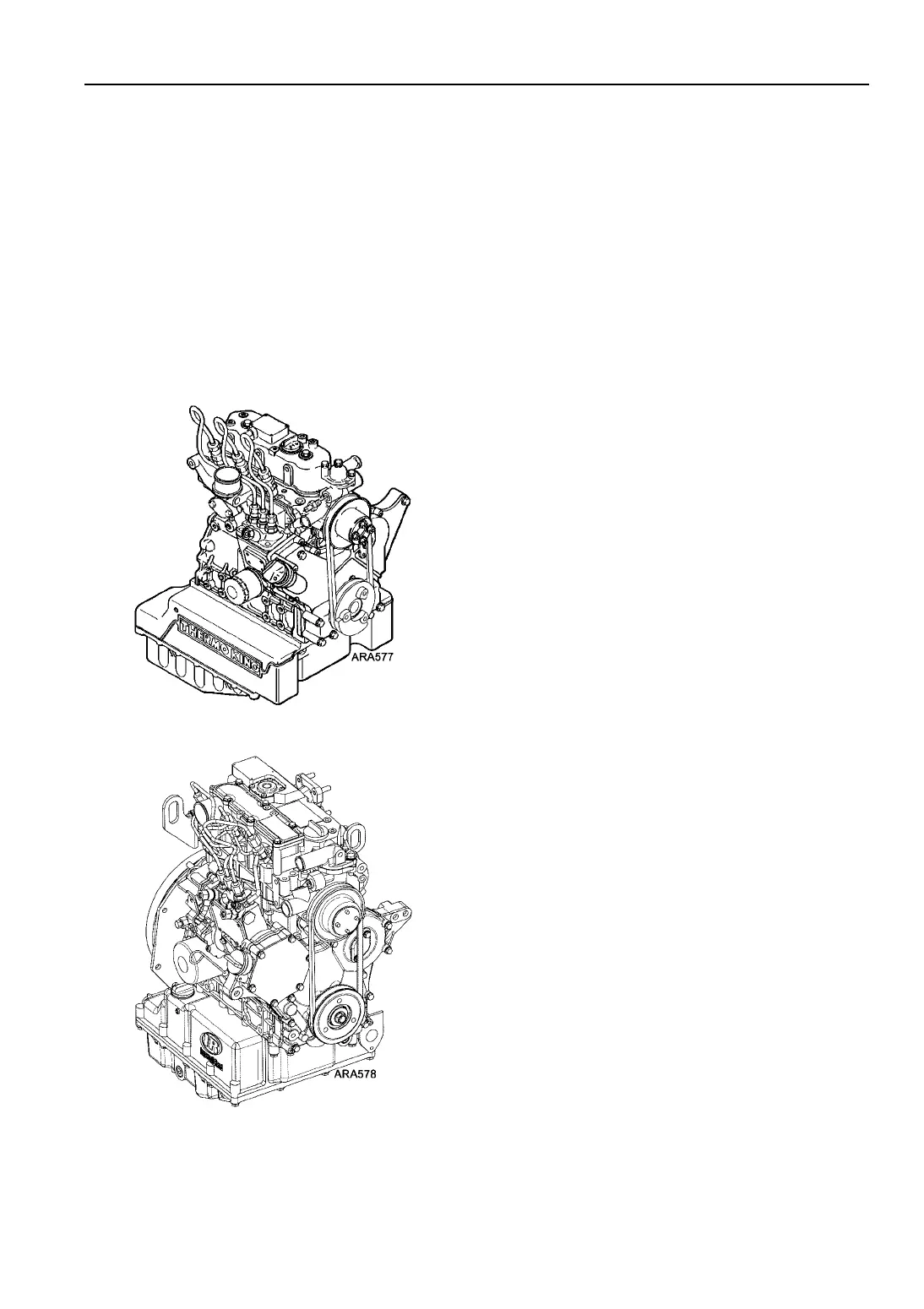

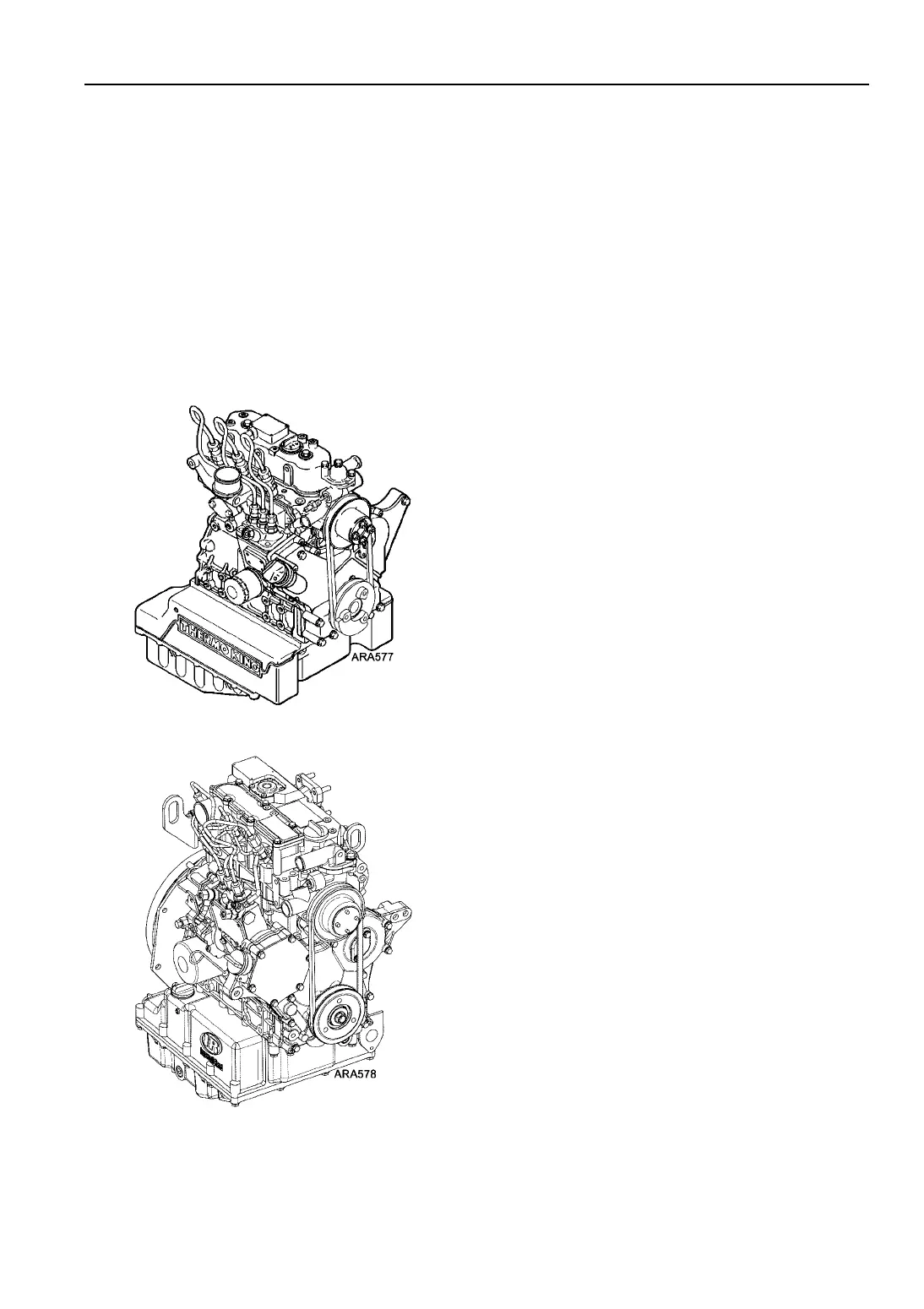

The most noticeable difference is that the valve

cover and intake manifold are separate on the

TK 3.95, but are an assembly on the TK376 (see

the following illustrations).

Figure 119: TK 3.95 (Tier 1)

Figure 120: TK376 (Tier 2)

EMI 2000

EMI 2000 is an extended maintenance interval

package. The EMI 2000 package consists of the

following key components:

• New EMI 2000-Hour Cyclonic Air Cleaner

Assembly and Air Cleaner Element (Standard

equipment on all TS units)

• New EMI 2000-Hour Fuel Filter (black with

gold lettering)

• New EMI 2000-Hour By-Pass Oil Filter

(black with gold lettering)

• API Rating CI-4 Mineral Oil (ACEA Rating

E3 or better for Europe)

• Five Year or 12,000 Hour ELC (Extended Life

Coolant).

The EMI package allows standard maintenance

intervals to be extended to 2,000 hours, or 1 year,

whichever occurs first.

NOTE: Units equipped with the EMI 2000

package do require regular inspection in

accordance with Thermo King's maintenance

recommendations.

Engine Lubrication System

The engine has a pressure lubrication system. See

the appropriate Engine Overhaul Manual for a

detailed description of the engine lubrication

system.

Oil pressure is affected by oil temperature,

viscosity and engine speed. Subnormal oil

pressures usually may be traced to lack of oil,

faulty relief valve or worn bearings. The use of

improper viscosity oil will also produce low oil

pressure shutdowns.

Loading...

Loading...