157

Structural Maintenance

Unit and Engine Mounting Bolts

Periodically check and tighten all unit and engine

mounting bolts. Torque the unit mounting

bolts to 60 ft-lb (81.3 N•m). Torque the engine

mounting bolts to 50 ft-lb (68 N•m).

Figure 182: Mounting Bolts

Unit Inspection

Inspect the unit during unit pretrip inspection and

scheduled maintenance inspections for loose or

broken wires or hardware, compressor oil leaks,

or other physical damage which might affect unit

performance and require repair or replacement of

parts.

Condenser and Radiator Coils

Clean the coils during scheduled maintenance

inspections. Remove any debris (e.g., leaves or

plastic wrap) that reduces the air flow. Clean dirty

coils with compressed air or a pressure washer. Be

careful not to bend the fins when cleaning a coil.

If possible, blow the air or water through the coil

in the direction opposite the normal air flow.

Repair bent fins and any other noticeable damage.

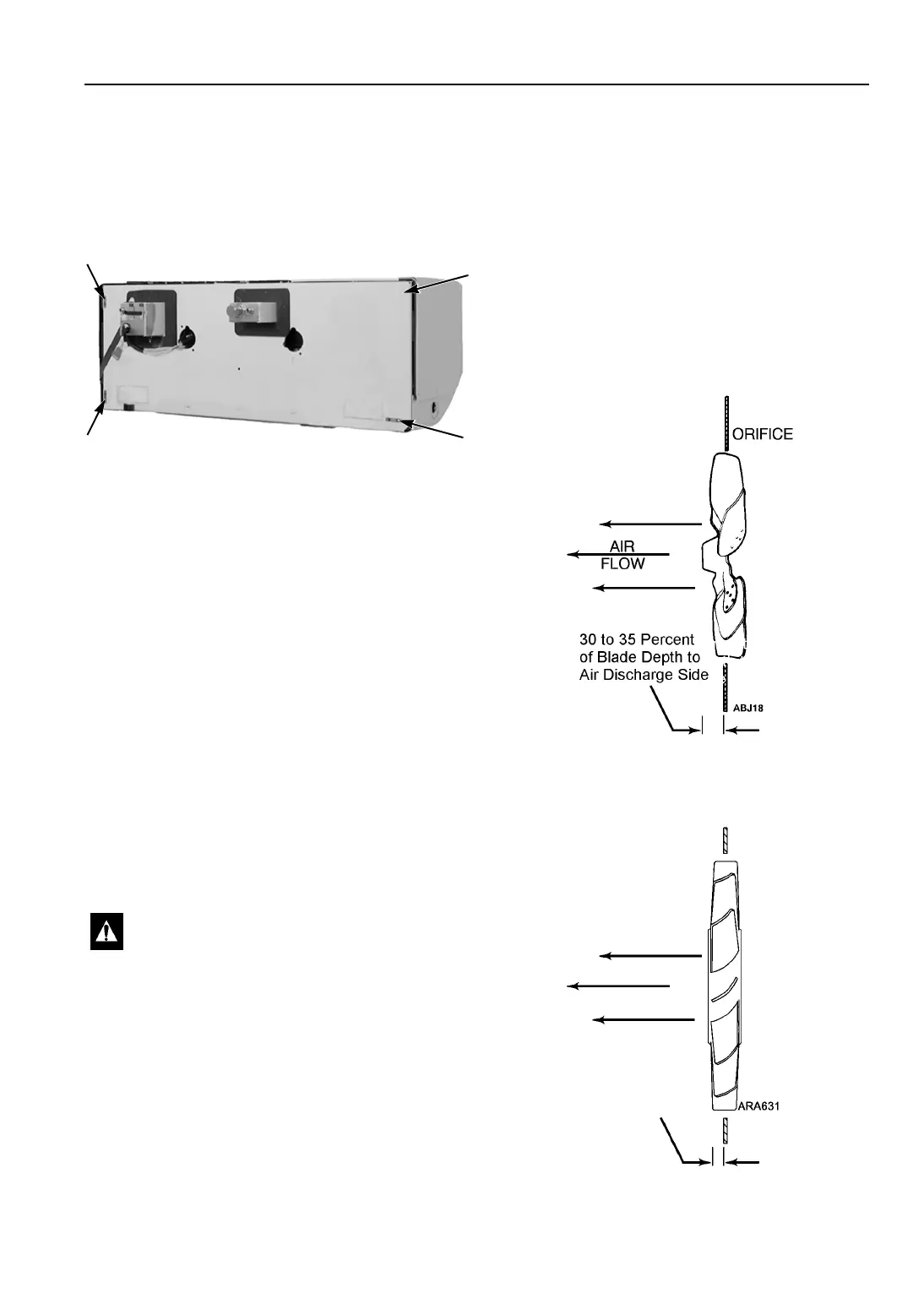

Fan Location

When mounting the fan and hub assembly on the

fanshaft, position the assembly in the orifice as

follows for proper fan performance:

• For all fans except the ten-blade condenser

fan, position the fan with 30 to 35 percent of

the blade width to the air discharge side.

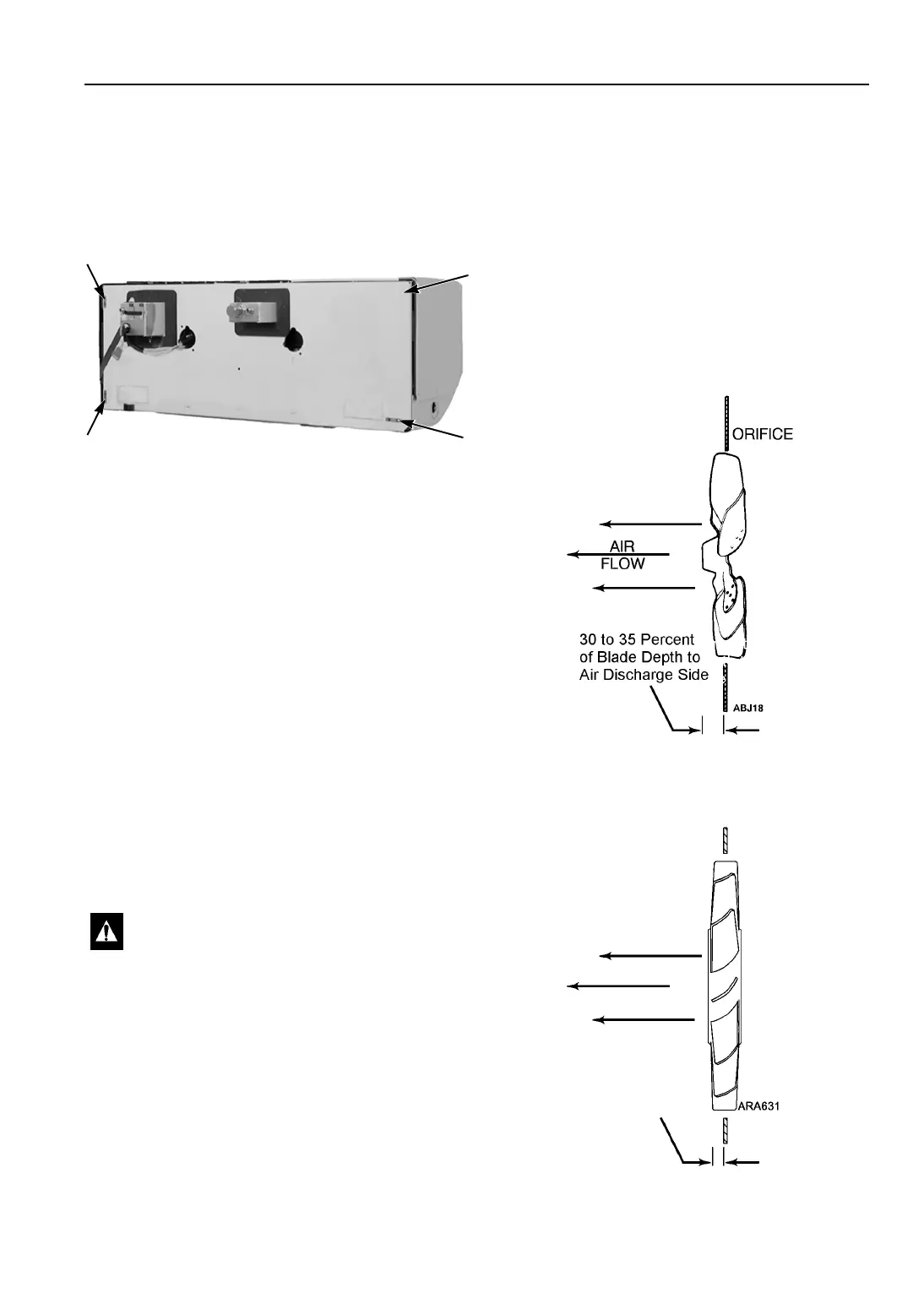

• For the ten-blade condenser fan, position the

fan with 50 percent of the blade width to the

air discharge side.

Figure 183: Fan Blade Position in Orifice

for All Except Ten-Blade Fan

Figure 184: Fan Blade Position in Orifice

for Ten-Blade Fan

CAUTION: Air pressure should not be

high enough to damage coil fins.

ORIFICE

AIR

FLOW

50 Percent

of Blade Depth to

Air Discharge Side

Loading...

Loading...