Engine Maintenance

98

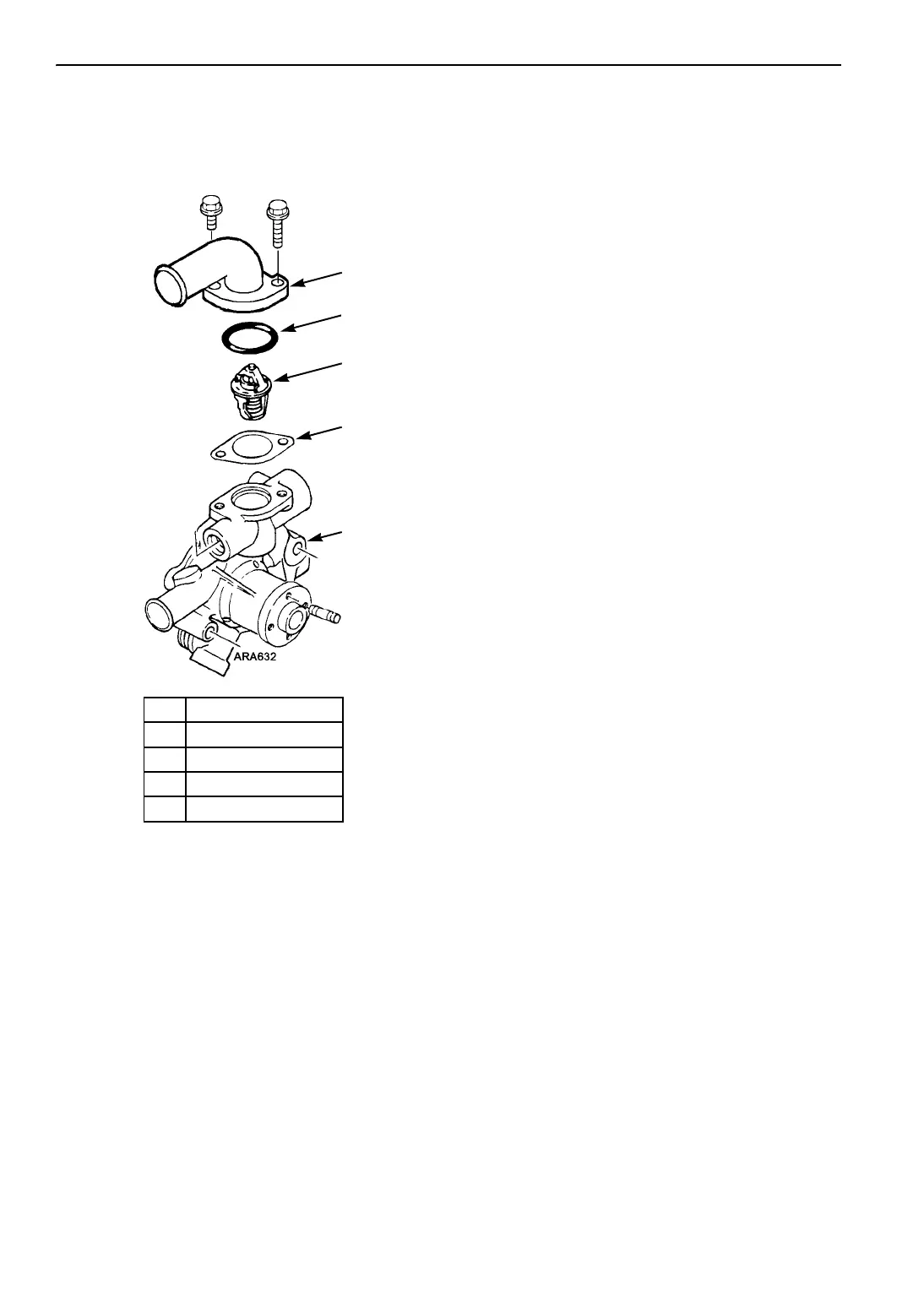

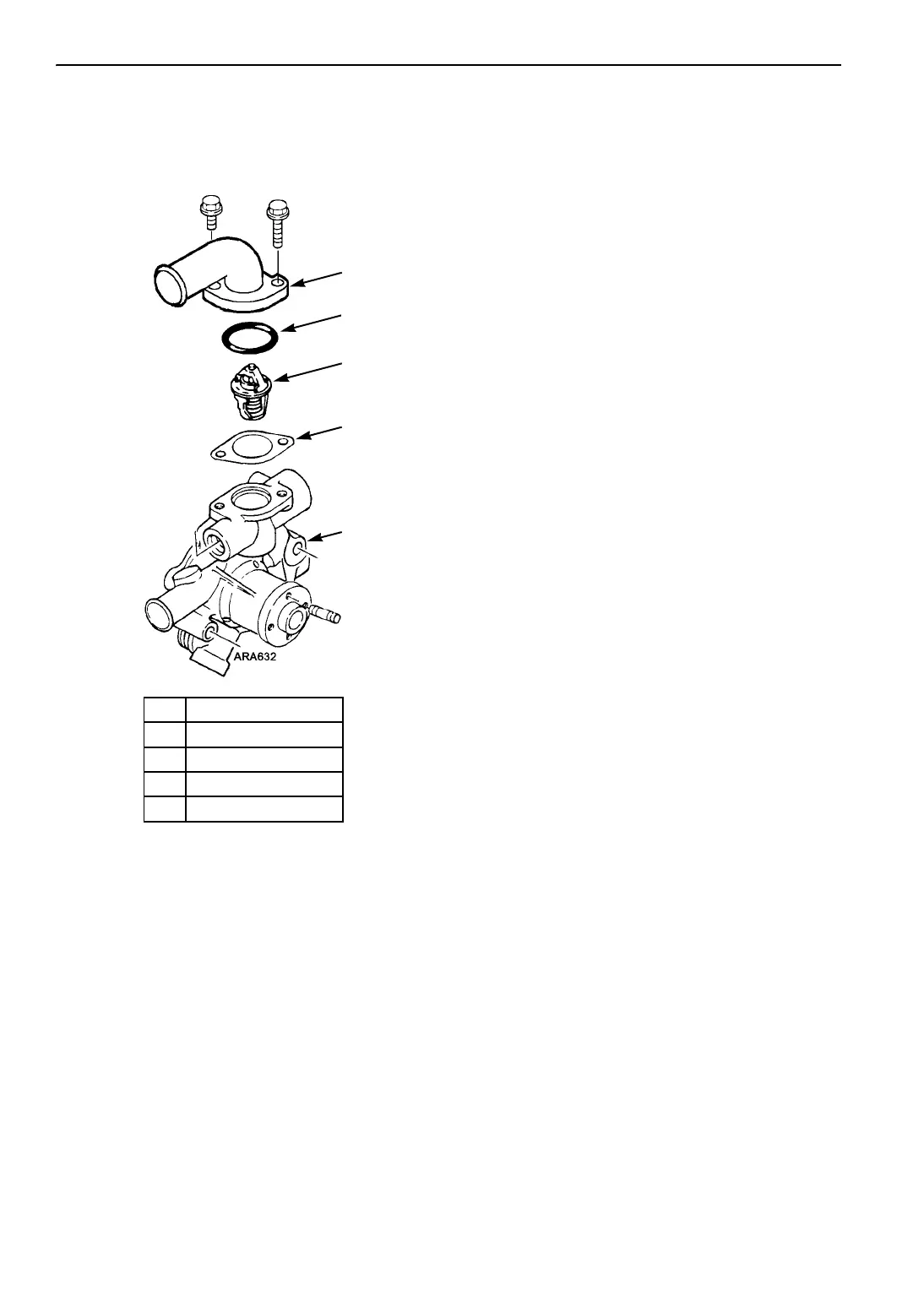

Engine Thermostat

For the best engine operation, use a 180 F (82 C)

thermostat year round.

Engine Fuel System

The fuel system used on these diesel engines is a

high pressure system used in conjunction with a

prechamber.

The components of the fuel system are:

• Fuel tank (may be the truck fuel tank)

• Electric Fuel pump

•Fuel filter

• Injection pump

• Injection nozzles.

A 10 psig (69 kPa) electric fuel pump pulls fuel

from the fuel tank through a fuel pump filter, then

pushes it to the fuel filter, and to the injection

pump. The prefilter is designed for diesel fuel and

is the only type that should be used.

The injection pump raises the pressure of the fuel

and meters the correct amount of fuel to the

nozzle at the correct time. The increased fuel

pressure will lift the spring loaded nozzle to admit

fuel into the combustion chamber.

The fuel system is relatively trouble free, and if

properly maintained will usually not require major

service repairs between engine overhauls.

The most common cause of fuel system problems

is contamination. It cannot be stressed enough that

the fuel must be clean, fuel tanks must be free

from contaminants, and the fuel filter must be

changed regularly. Any time that the fuel system

is opened up, all possible precautions must be

taken to keep dirt from entering the system. This

means all fuel lines should be capped when open.

The work should be done in a relatively clean

area, if possible, and the work should be

completed in the shortest time possible.

1. Thermostat Housing

2. Gasket

3. Thermostat

4. Gasket

5. Water Pump

Figure 127: Water Pump Assembly and Thermostat

1

2

3

4

5

Loading...

Loading...